Method for separating blend fibers from worn out clothes

A technology of blended fiber and separation method, which is applied in the directions of fiber treatment, decomposition of fiber-containing substances, decomposition and restoration of textiles, etc., which can solve the problems of fiber consumption, difficulty in reusing, and increase in the number of textiles, so as to reduce pollution and facilitate circular operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The waste clothes treated in this embodiment only contain polyester / cotton mixed fibers and have not been dyed.

[0032] Pre-treatment (steps (1) and (2)): Clean the waste clothes to be treated, remove solids and other impurities, dry them, and then fully separate them through a three-roller automatic opening machine (the diameter of the licker-in roller is 730mm) to obtain Cotton-like fibers are then combed by a carding machine to separate the fibers into a single fiber state and spread into a thin net state.

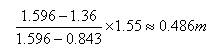

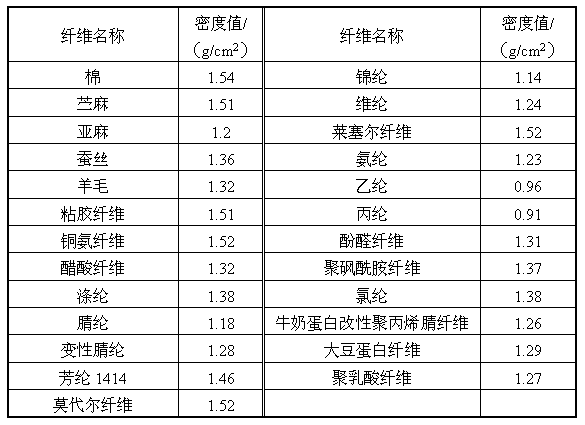

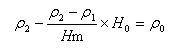

[0033] Separation (step (3)): Immerse the above-mentioned polyester / cotton mixed fiber in a thin net shape into the separation liquid of the separation tank, soak and let it stand for 24 hours, and the final solution height Hm is measured to be 1.4m, and the distance between the cotton and the bottom of the separation tank is H 01 for:

[0034]

[0035] Height H of polyester from the bottom of the separation cylinder 02 for:

[0036]

[0037] That is: t...

Embodiment 2

[0042] In this embodiment, the garment or fabric to be treated is made of polypropylene / cotton / wool blended fiber and is dyed.

[0043]Pre-treatment (steps (1) and (2)): Clean the waste clothes to be treated, remove solids and other impurities, and then put them in petroleum ether for further cleaning to remove dyes, pigments, pastes, coatings, etc. Inorganic matter, and then placed for 15 days, after the petroleum ether is fully volatilized and dried, it is fully separated by a three-roller automatic opener (the diameter of the licker-in roller is 730mm) to obtain cotton-like fibers, and then combed by a carding machine to separate the fibers into Single fiber state, and spread into a thin mesh state.

[0044] In the separation stage: immerse the thin mesh fiber after pretreatment into the separation liquid of the separation cylinder, and after soaking and standing for 48 hours, the final solution height Hm is measured to be 1.45m, and the distance between the cotton and the ...

Embodiment 3

[0055] In this embodiment, the clothes or fabrics to be treated are made of polyester / silk / wool blended fibers and are dyed.

[0056] Pre-treatment (steps (1) and (2)): Clean the waste clothes to be treated, remove solids and other impurities, and then put them in petroleum ether for further cleaning to remove dyes, pigments, pastes, coatings, etc. Inorganic matter, and then placed for 10 days, after the petroleum ether is fully volatilized and dried, it is fully separated by a three-roller automatic opener (the diameter of the licker-in roller is 730mm) to obtain cotton-like fibers, which are then combed by a carding machine to separate the fibers into Single fiber state, and spread into a thin mesh state;

[0057] In the separation stage: immerse the thin mesh fiber after pretreatment in the separation liquid of the separation cylinder, and measure after soaking and standing for 48 hours. The separation cylinder is a cylindrical glass container with a length scale, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com