Production method of polyester/polypropylene double-layer woven sportswear fabric

A production method, polypropylene technology, applied in the direction of fabrics, textiles, multi-strand fabrics, etc., can solve the problems of affecting reasonable deployment, discomfort, easy threading, etc., and achieve the effect of reducing weight, good acid and alkali resistance, and feeling warm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

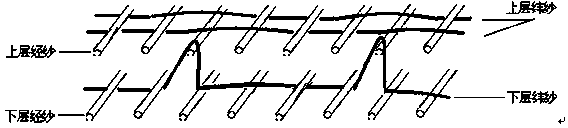

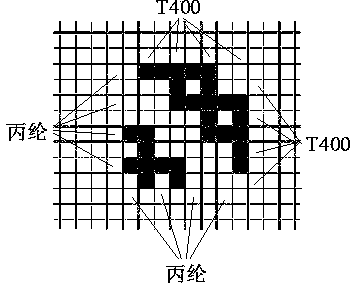

[0016] 63" (T75D / T400+PP 75D / 48F twisted) (1:1) X (T75D / T400+PP 75D / 48F twisted) (1:1), 200x160 double-layer gray fabric production. Fabric structure figure 1 .

[0017] 1. Selection of raw materials: T75D / T400 raw materials have good elasticity, and it is difficult to avoid inconsistencies in the bobbins (including winding tension and forming) during the production or handling of raw materials. When used as warp raw materials, it is especially not allowed to cause any discrepancies. The effect of fabric dyeing. Therefore, first of all, the raw material suppliers are required to carry out a sock dyeing test for each polyester T400 bobbin entering the factory, so as to ensure the consistency of the warp yarn raw material and the dyeing consistency of the subsequent fabric. There are differences. Defective bobbins are not allowed to be used, while polypropylene twisted yarn does not need to be dyed test, but it needs to be checked one by one to ensure that the bobbin quality w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com