Partitioning hole-arrangement energy-consumption steel sheet wall

A steel plate wall and steel plate technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of concentrated plastic distribution of energy-consuming steel plates, and achieve the effects of large lateral stiffness, improved seismic performance, and high bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

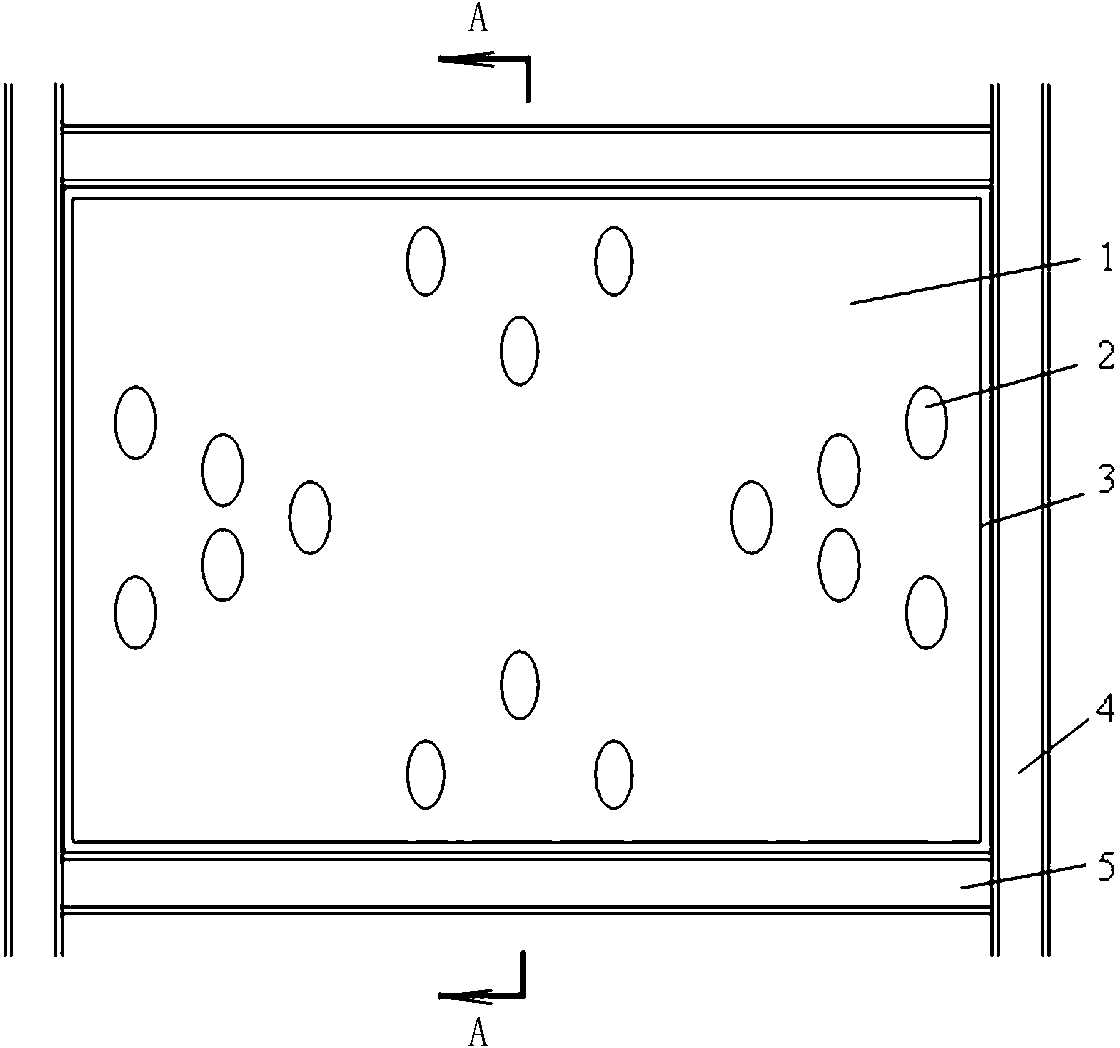

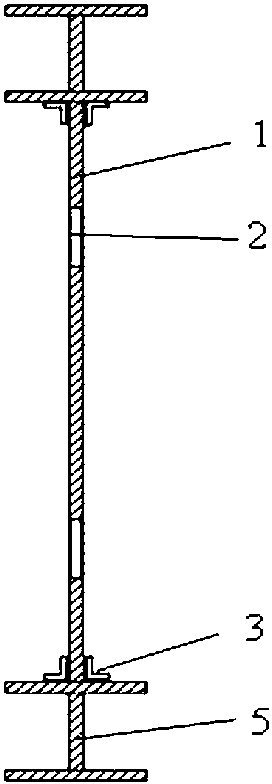

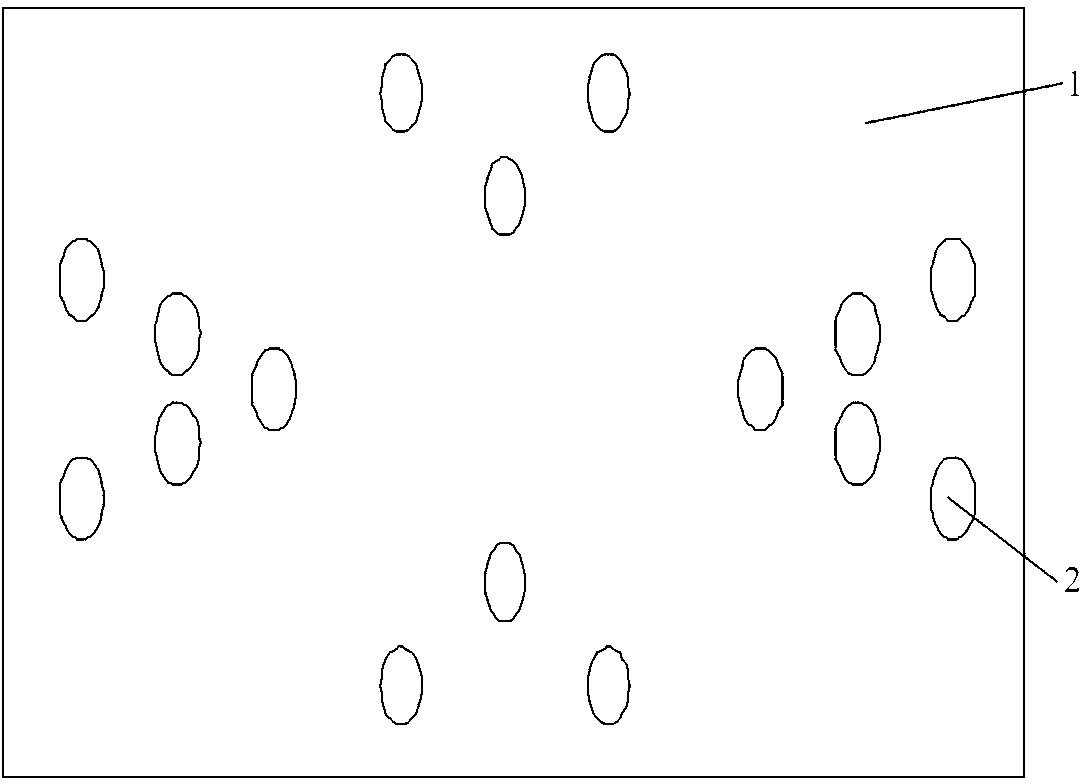

[0018] Such as figure 1 , 2 The energy-dissipating steel plate wall with partition holes of the present invention shown in . The two main diagonals of the steel plate 1 are set as non-arranged elliptical inner hole 2 areas, and the two main diagonals divide the inner filling steel plate 1 into four triangular areas, and the elliptical inner holes 2 in each area are triangular The elliptical internal holes 2 in the entire inner filling steel plate 1 are arranged at most two vertically and at most three horizontally, and the long axis of the elliptical internal holes 2 is vertically arranged. Determine the size of the inner filling steel plate 1 according to the actual project, the position and size of the inner hole 2, the inner filling steel plate 1, the steel column 4 and the steel beam 5 use angle steel as the connecting piece 3 and install the inner filling steel plate 1 on the steel beam 5 through bolts with steel column 4 on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com