Engine EGR (exhaust gas recirculation) system

A recirculation system and exhaust gas recirculation technology, applied in exhaust gas recirculation, engine components, combustion engines, etc., can solve the problem of reducing the durability of plastic intake manifolds, reducing the temperature of engine circulating water, and prolonging engine warm-up time, etc. problems, to achieve the effect of shortening the warm-up time, increasing the intake air volume, and reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

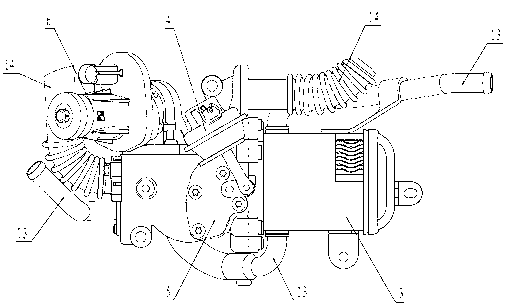

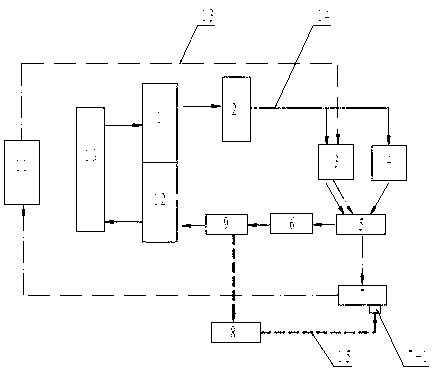

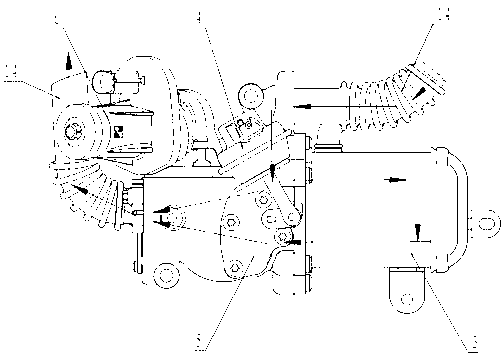

[0020] See Figure 1, figure 2 , the present invention includes a cooling water circulation mechanism and an exhaust gas recirculation mechanism, the cooling water circulation mechanism communicates with the vehicle radiator 11, the cooling water circulation mechanism adjusts the temperature of the recirculated exhaust gas under the control of the engine ECU 8, and the exhaust gas recirculation mechanism It is arranged between the engine exhaust manifold 2 and the exhaust gas intake channel 12 of the engine cylinder head. The present invention uses the electronic water pump 7 to control the cooling water flow rate of the electronic water pump 7 through the signal sent by the temperature sensor 9 to the engine ECU 8 (or the nitrogen oxide content detected by the emission detection system), so as to realize the control of the cooling capacity of the EGR system , when the recirculation exhaust gas temperature is higher than the actual demand temperature, adjust the electronic wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com