Herringbone gear shaft and production method thereof

A manufacturing method and gear shaft technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of not being able to meet the processing needs of herringbone gear shafts, mass production, and manpower Problems such as the word gear shaft, to achieve the effect of high detection efficiency, low manufacturing cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the specific drawings.

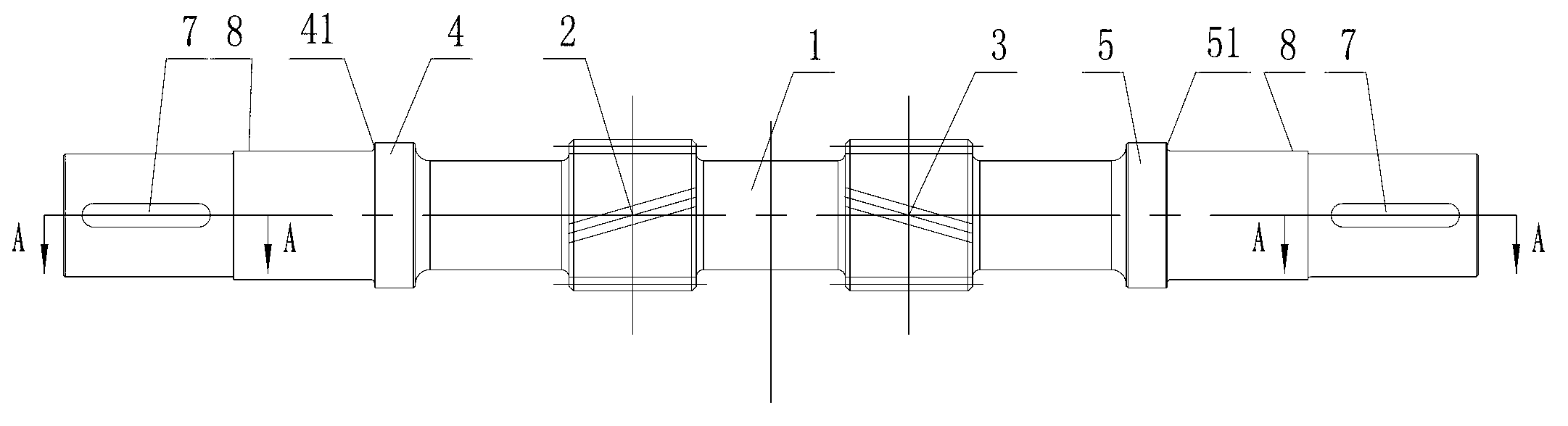

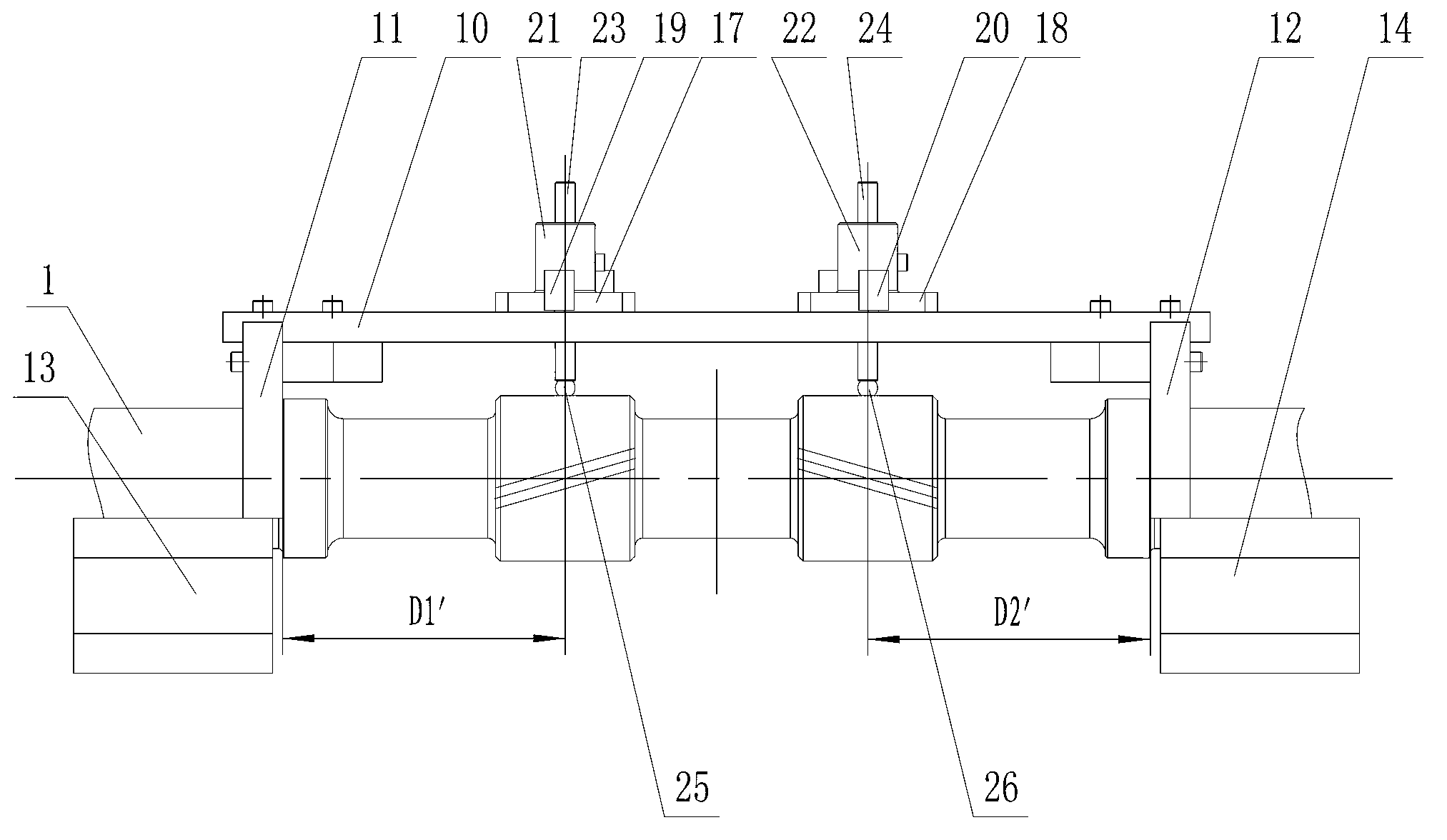

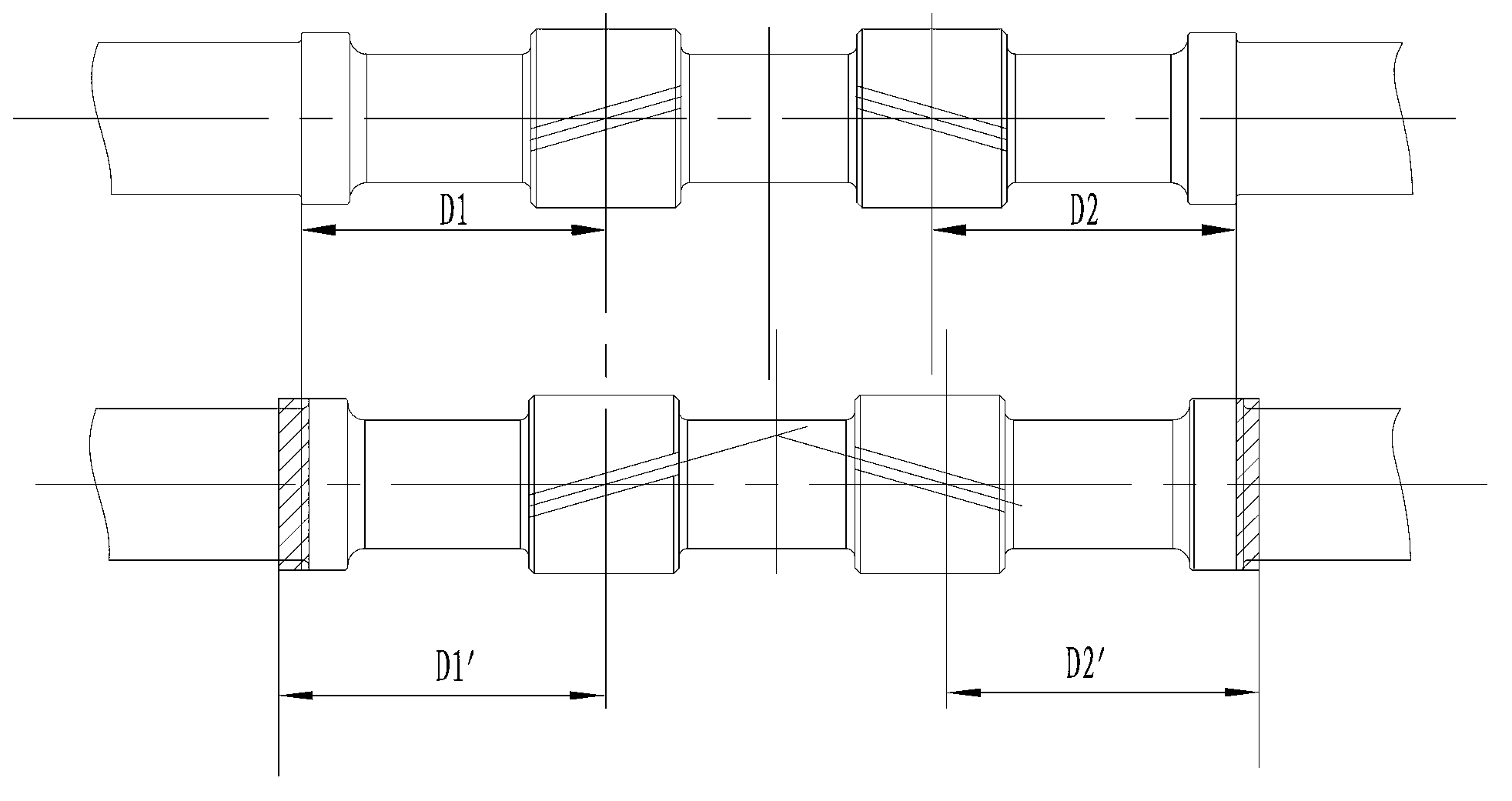

[0034] like figure 1 , Figure 4 As shown: the herringbone gear shaft includes a shaft body 1, a left-handed gear 2, a right-handed gear 3, a left positioning shoulder 4, a right positioning shoulder 5, a left positioning surface 41, a right positioning surface 51, a screw hole 6, and a keyway 7. Oil seal shoulder 8, etc.

[0035] like figure 1 , Figure 4 As shown, the herringbone gear shaft of the present invention includes a shaft body 1, a left-handed gear 2 and a right-handed gear 3 are fixed in the middle of the shaft body 1, and the left-handed gear 2 and the right-handed gear 3 are arranged symmetrically on the center line of the shaft body 1. Both sides; the left positioning shoulder 4 and the right positioning shoulder 5 are respectively fixed on the shaft body 1 on the outside of the left-handed gear 2 and the right-handed gear 3, the outer end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com