Method for designing oscillating tooth transmission speed reducer

A technology of movable tooth transmission and design method, which is applied in instruments, calculations, special data processing applications, etc., can solve the problems of inability to meet the needs of industrialization, long development cycle of reducers, etc., to shorten development time, reduce production costs, and make reasonable Effects of Tolerance Assignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in combination with specific embodiments.

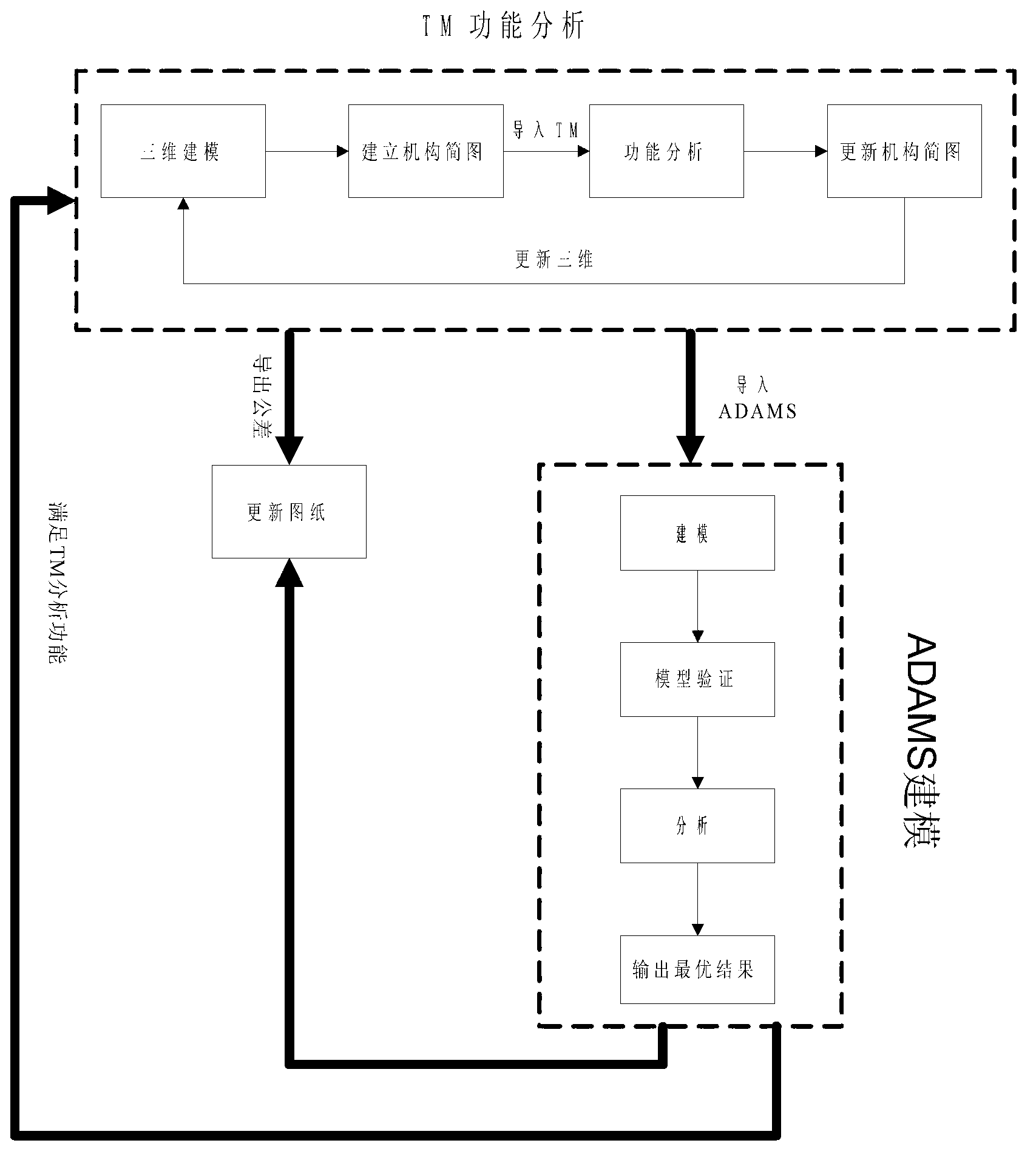

[0020] In this embodiment, a roller movable tooth transmission reducer is taken as an example for illustration, and the design process is realized based on ADAMS dynamic simulation analysis software.

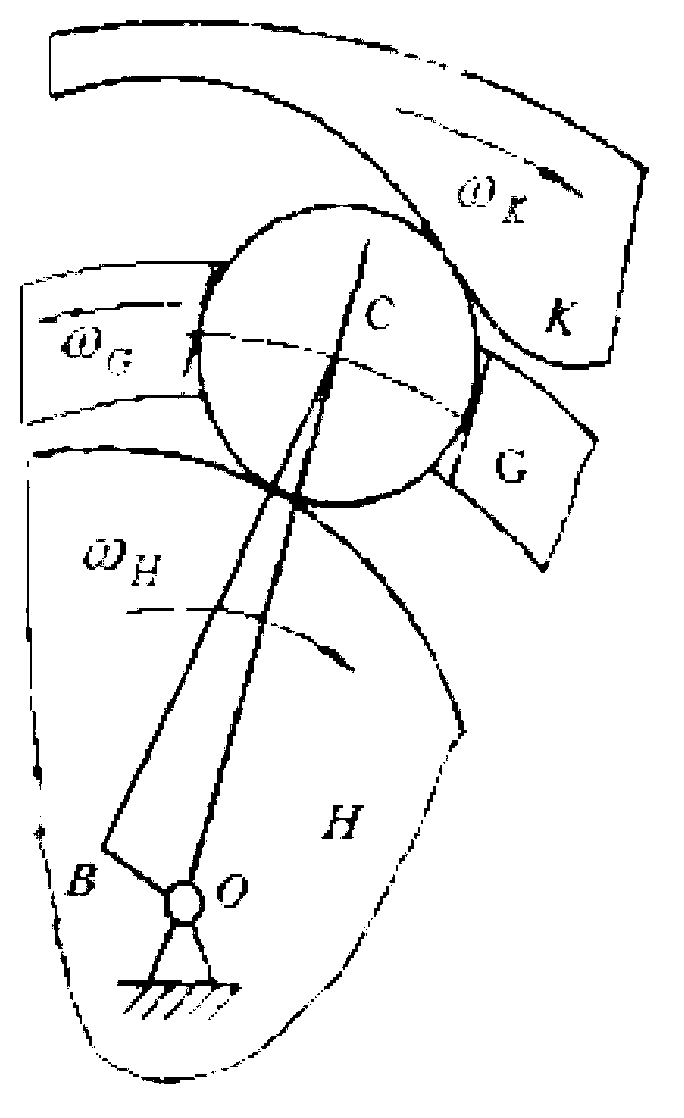

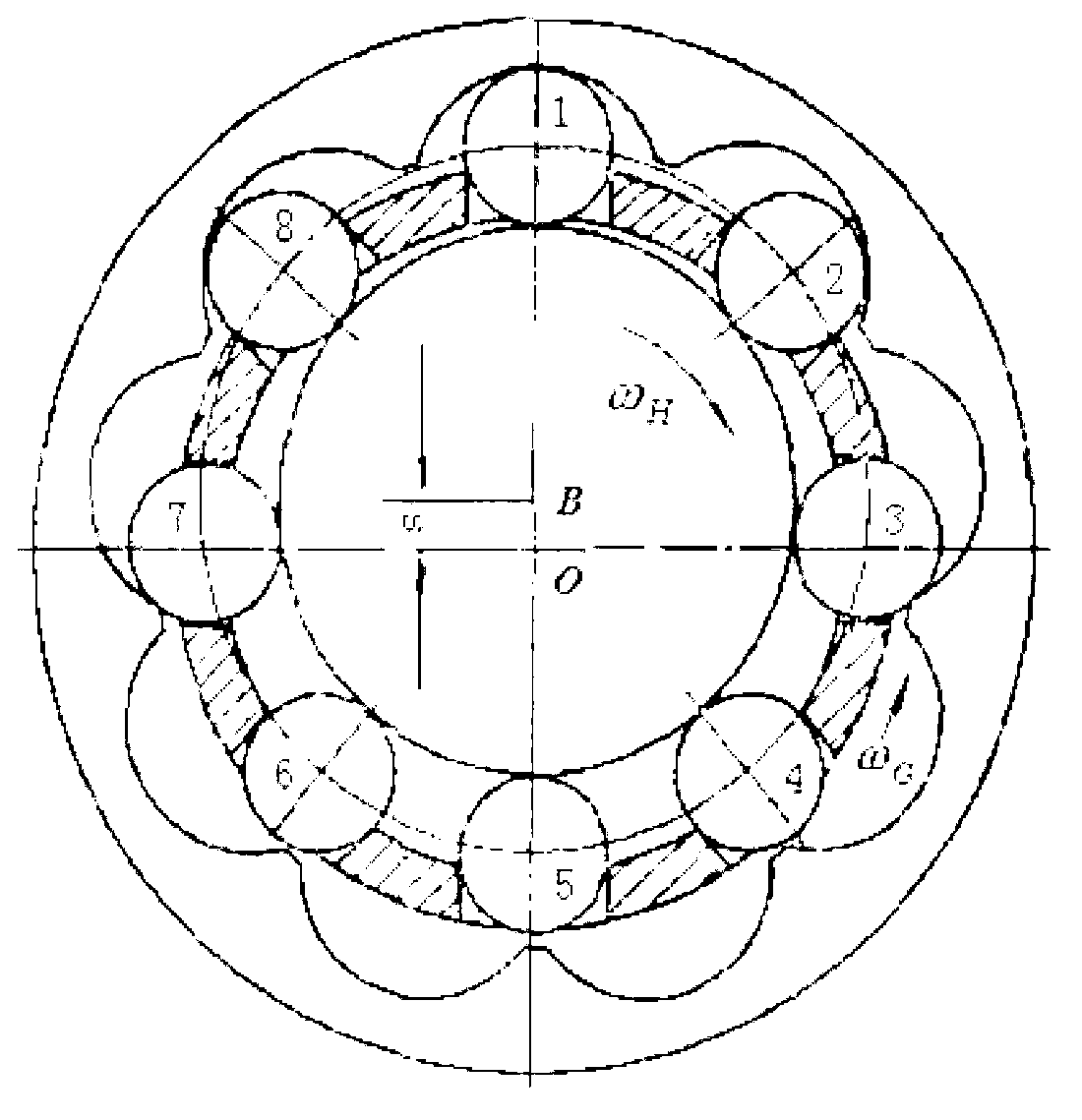

[0021] The structure of the roller movable tooth transmission reducer is as follows: Figure 1-2 As shown, the roller movable tooth transmission consists of three basic components: the center wheel K, the movable gear G and the shock wave device H. The geometric center of the shock wave H is B, and the rotation center is 0. The movable gear G is made up of a group of roller movable teeth (bearing rollers) in the movable rack and its radial guide groove. If the center wheel is fixedly connected with the base, the output of the movement is finally completed by the movable gear frame, and the connection between the movable gear frame and the output shaft can be integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com