Coarse Copper Deposition Method for Full Board Cover Film Rigid-Flex Board

A soft-rigid combination board and cover film technology, which is applied in the direction of electrical connection formation of printed components, can solve the problems of excessive bite corrosion of the cover film, hidden dangers of quality and safety, and unsatisfactory effect, and achieve the effect of avoiding serious bite corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

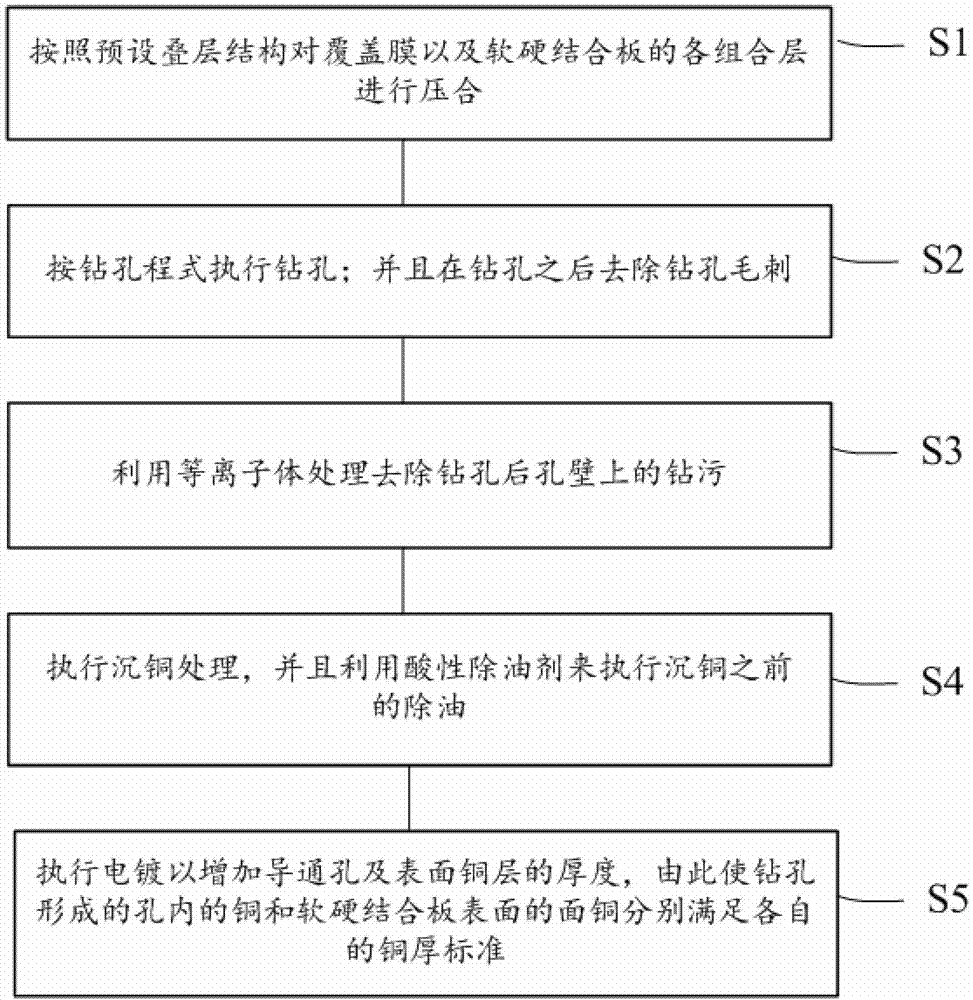

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0020] The full-board cover film rigid-flex board has a cover film exposed on the hole wall after drilling; among them, for example, the cover film is generally a double-layer structure composed of a carrier film layer and an adhesive layer; and among them, the adhesive layer material is generally acidic. Polyacrylate; carrier film layer is generally PI (polyimide) material. Acidic polyacrylate overlays are more susceptible to attack by alkaline solutions, including the roughening solution potassium permanganate and alkaline degreasers for copper wire.

[0021] In view of the fact that the acidic polyacrylate cover film cannot be roughened by a conventional potassium permanganate system, nor can it be subjected to an alkaline degreaser; Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com