Copper member having hybrid joint structure for forming sealed space, and joining method thereof

A closed space, mixed bonding technology, applied in the direction of connecting components, instrument parts, electrical equipment structural parts, etc., can solve the problems of weakened bond strength between adhesive and copper plate, copper plate deformation, oxidation, etc., to achieve Improves heat dissipation, prevents wear and oxidation, and improves durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In describing the embodiments with reference to the drawings, the same reference numerals used in different drawings denote the same or similar components, and repeated description will be omitted.

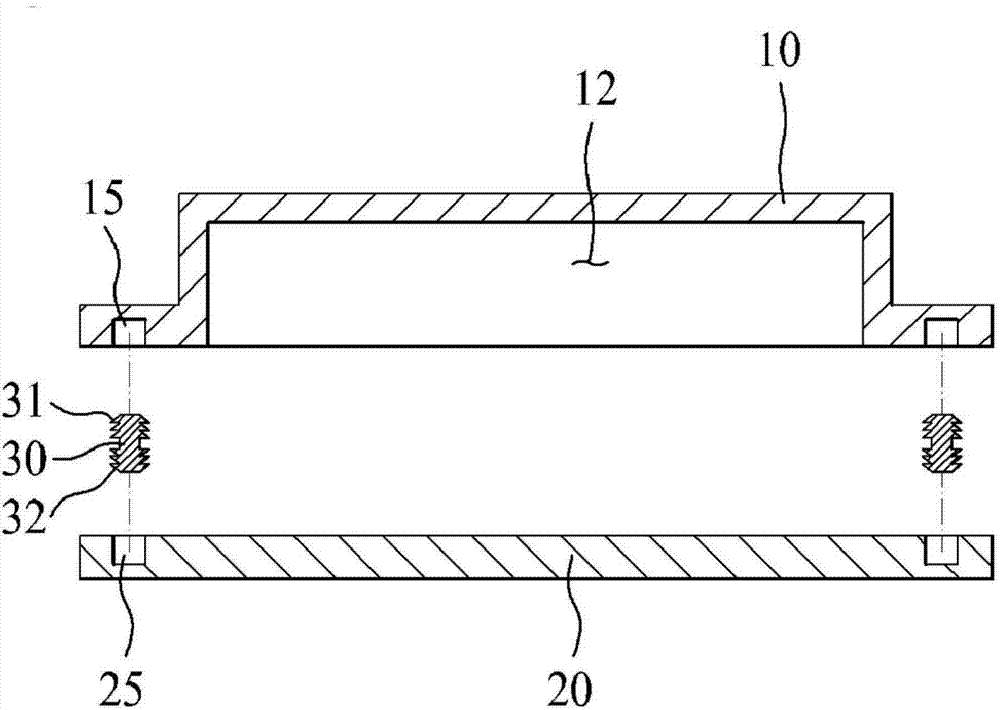

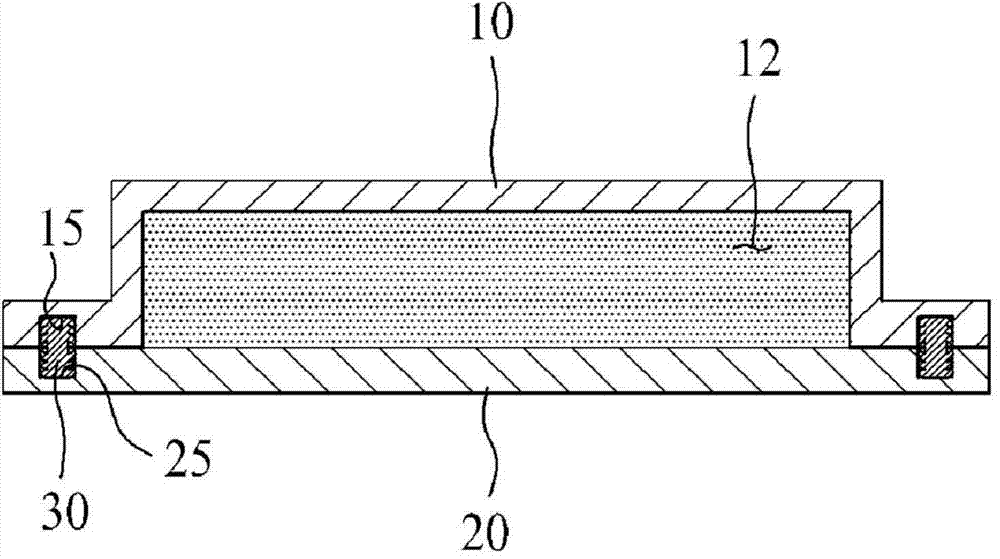

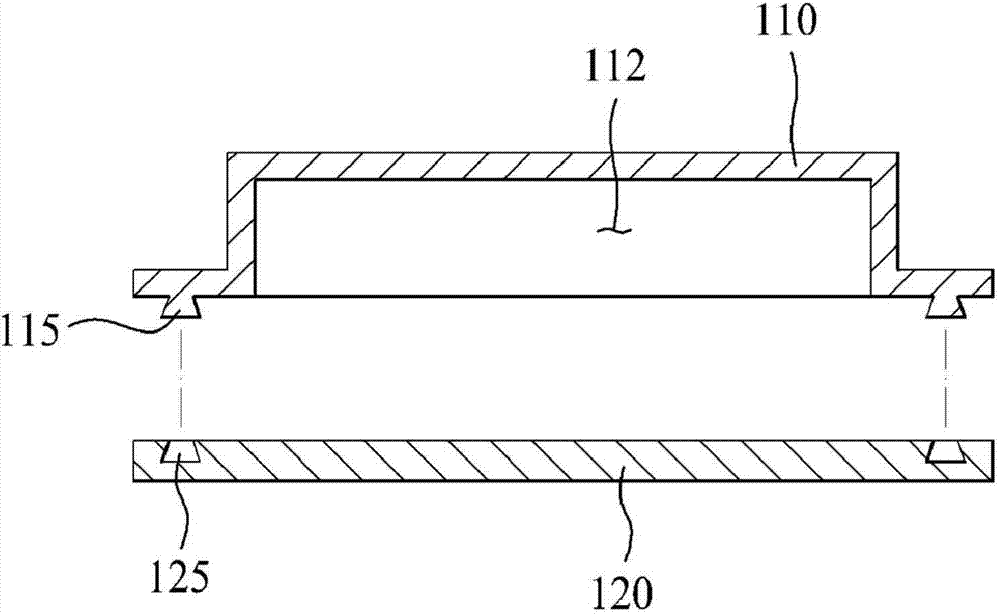

[0047] Such as figure 1 As shown, the copper component with a closed space according to the first embodiment of the present invention includes a main body including an upper connection plate 10 and a lower connection plate 20 .

[0048] The upper connecting plate 10 is located on the upper part of the copper component and has an exposed surface exposed to the outside, so that the upper connecting plate 10 conducts heat to the outside to release the heat generated by the circuit board. In addition, the upper gusset 10 has, on the opposite side of its exposed face, a first adhesive face which is in direct contact with and fastened to the lower gusset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com