A method for preparing a transparent wear-resistant film suitable for watch parts

A wear-resistant film and transparent technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of non-wear resistance, anti-corrosion performance decline, low hardness of stainless steel, etc., and achieve remarkable ductility and combination Good strength and low film brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

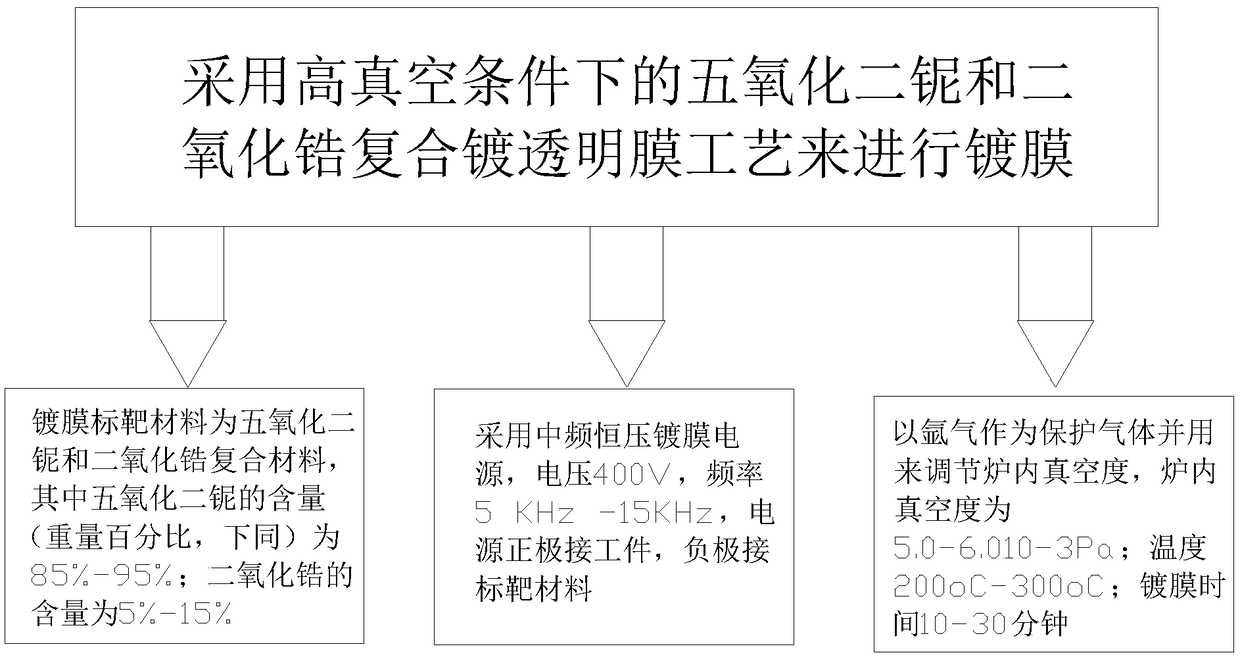

[0018] Using niobium pentoxide and zirconium dioxide composite coating transparent film technology under high vacuum conditions: the coating target material is niobium pentoxide and zirconium dioxide composite material, wherein the content of niobium pentoxide (weight percentage, the same below) 85%-95%; the content of zirconia is 5%-15%; using intermediate frequency constant voltage coating power supply, coating voltage 400V, frequency 5KHz-15KHz, the positive pole of the power supply is connected to the workpiece, and the negative pole is connected to the target material; Argon gas is used as the The protective gas is used to adjust the vacuum degree in the furnace, and the vacuum degree in the furnace is 5.0-6.0×10 -3 Pa; temperature is 200°C-300°C; coating time is 10-30 minutes.

Embodiment 2

[0020] Adopt niobium pentoxide and zirconium dioxide composite transparent film coating technology under high vacuum conditions: directly apply niobium pentoxide and zirconium dioxide transparent composite film on the infiltrated layer, and the content of niobium pentoxide in the target material is 85% %; the content of zirconia is 15%; the coating voltage is 400V, the frequency is 15KHz, the positive electrode of the power supply is connected to the workpiece, and the negative electrode is connected to the target material; argon is used as a protective gas to adjust the vacuum degree in the furnace. 6.0×10 -3 Pa; the temperature is 300°C; the coating time is 30 minutes, and a transparent film layer with a thickness of about 2 microns can be formed.

Embodiment 3

[0022] Niobium pentoxide and zirconium dioxide composite coating transparent film technology under high vacuum conditions: apply niobium pentoxide and zirconium dioxide transparent composite film on the rose gold plating (film) layer, and the target material is niobium pentoxide The content of zirconium dioxide is 95%; the content of zirconia is 5%; the coating voltage is 400V, the frequency is 5KHz, the positive electrode of the power supply is connected to the workpiece, and the negative electrode is connected to the target material; argon is used as a protective gas to adjust the vacuum in the furnace. The degree is 5.0-6.0×10 -3 Pa; the temperature is 200°C; the coating time is 10 minutes, and a transparent film layer with a thickness of about 0.5 microns can be formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com