Motor-driven ring-cutting anastomat

A circumcision and electric technology, applied in the field of medical devices, can solve the problems of manual safety control device, increase in size, cost, unfavorable marketization, etc., and achieve the effect of improving the probability of success, reducing the processing cost, and improving the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

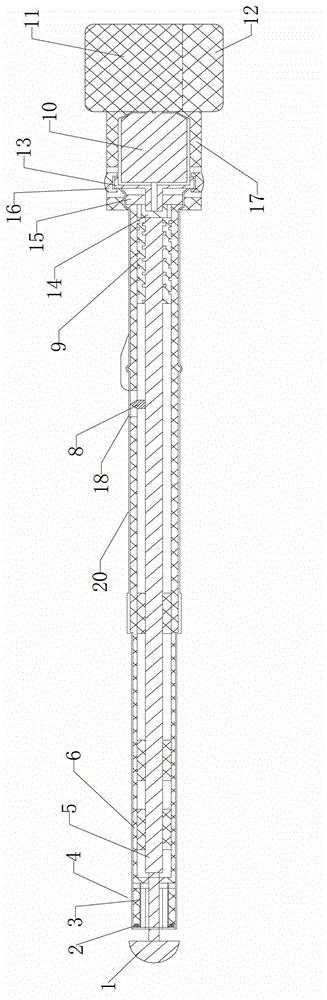

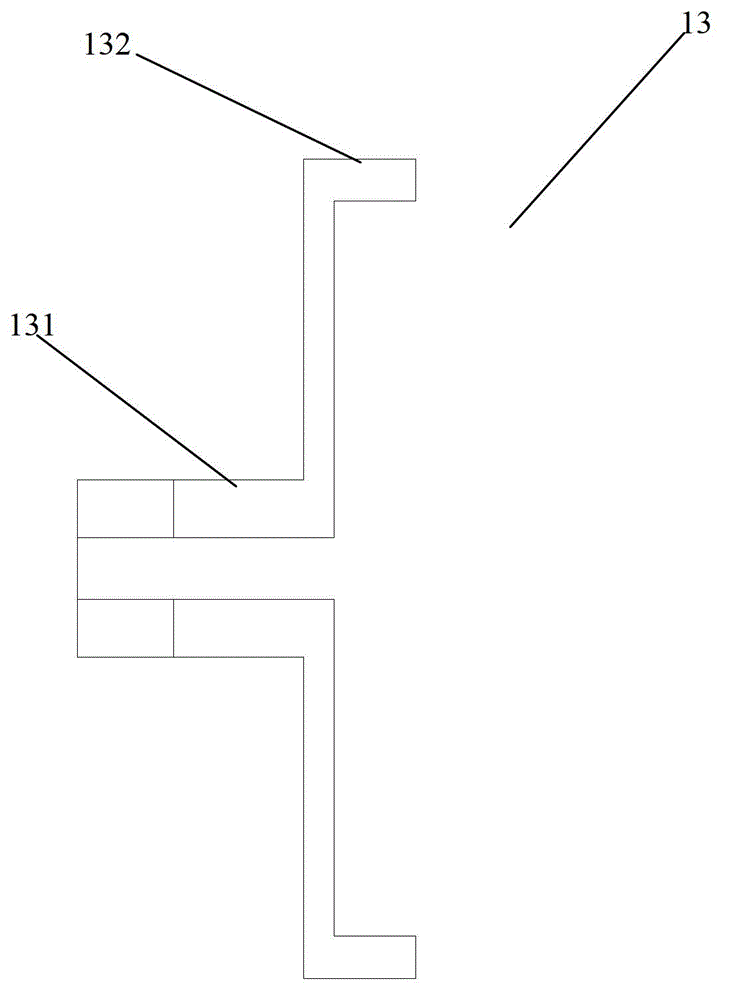

[0022] Such as figure 1 As shown, the electric circumcision kisser of the present invention includes a kiss-cutting mechanism 4 and a drive actuator. The drive actuator includes a cylindrical tube body 20, which is fixedly arranged at the inner rear end of the tube body and the inner and outer walls are respectively formed with A threaded transmission solenoid 9, a central rod 5 arranged inside the tube body and connected to the abutment seat at the front end and the rear end threadedly engaged with the inner part of the driving solenoid, arranged inside the tube body and after the front section is connected to the ring knife and the staple cartridge in transmission The push tube 6 whose end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com