High pressure forming method for increasing crystallinity of polylactic acid

A technology of high-pressure molding and polylactic acid, which is applied in the field of polymer materials, can solve problems such as unreported and uneven dispersion, and achieve the effects of broadening the application range, high production efficiency, easy control and popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

[0021] (1) Drying: first place the polylactic acid particles in a vacuum oven, evaporate and remove internal moisture under vacuum conditions, the oven temperature is 60°C, and the drying time is 12 hours until the moisture weight content is less than 0.01%;

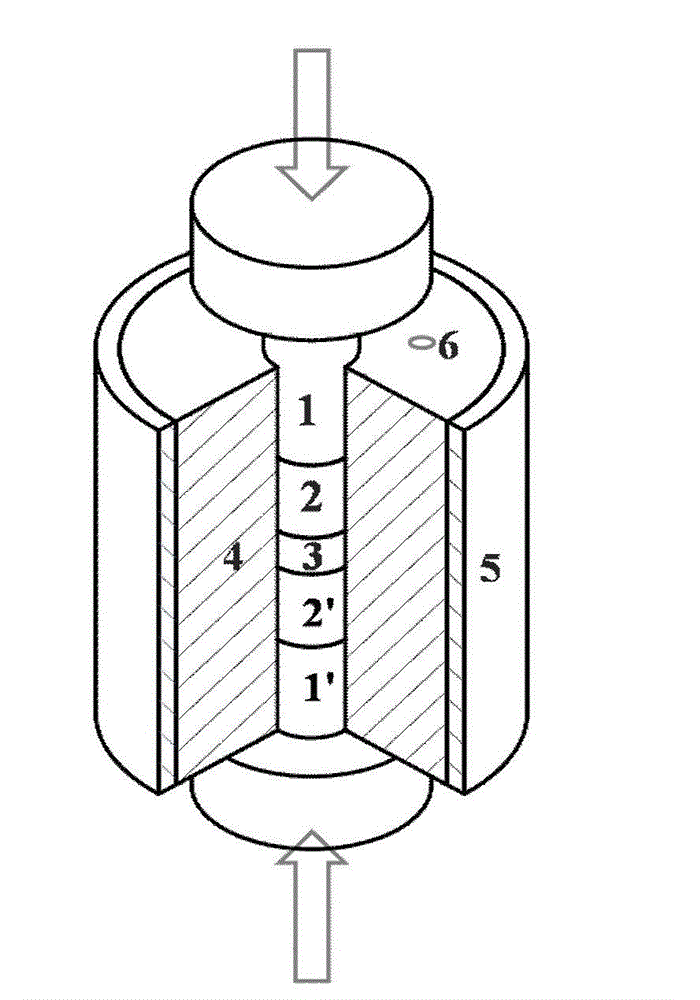

[0022] (2) High-pressure molding: first place the dried polylactic acid particles in a high-pressure mold, then raise the temperature to 185°C, and maintain it for a long enough time until the heat history is completely eliminated, and then slowly cool at a rate of 2.5°C / min until molding temperature (120-185° C.), and then apply a pressure of 300-1500 MPa and maintain it for 0.5-24 hours for isothermal crystallization, and finally release the pressure after the temperature drops to room temperature. In order to prevent polylactic acid from degrading under high temperature and pressure, the samples need to be molded in a nitrogen-protected environment. The specific molding temperature and pressure are shown in Table 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com