Directional arrangement method for nickel-supported multi-walled carbon nanotubes

A technology of multi-walled carbon nanotubes and directional arrangement, which is applied in the process of producing decorative surface effects, decorative arts, gaseous chemical plating, etc. Narrow scope, complex process and other problems, to achieve the effect of improving physical and chemical properties and mechanical properties, accurate and accurate data, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with accompanying drawing:

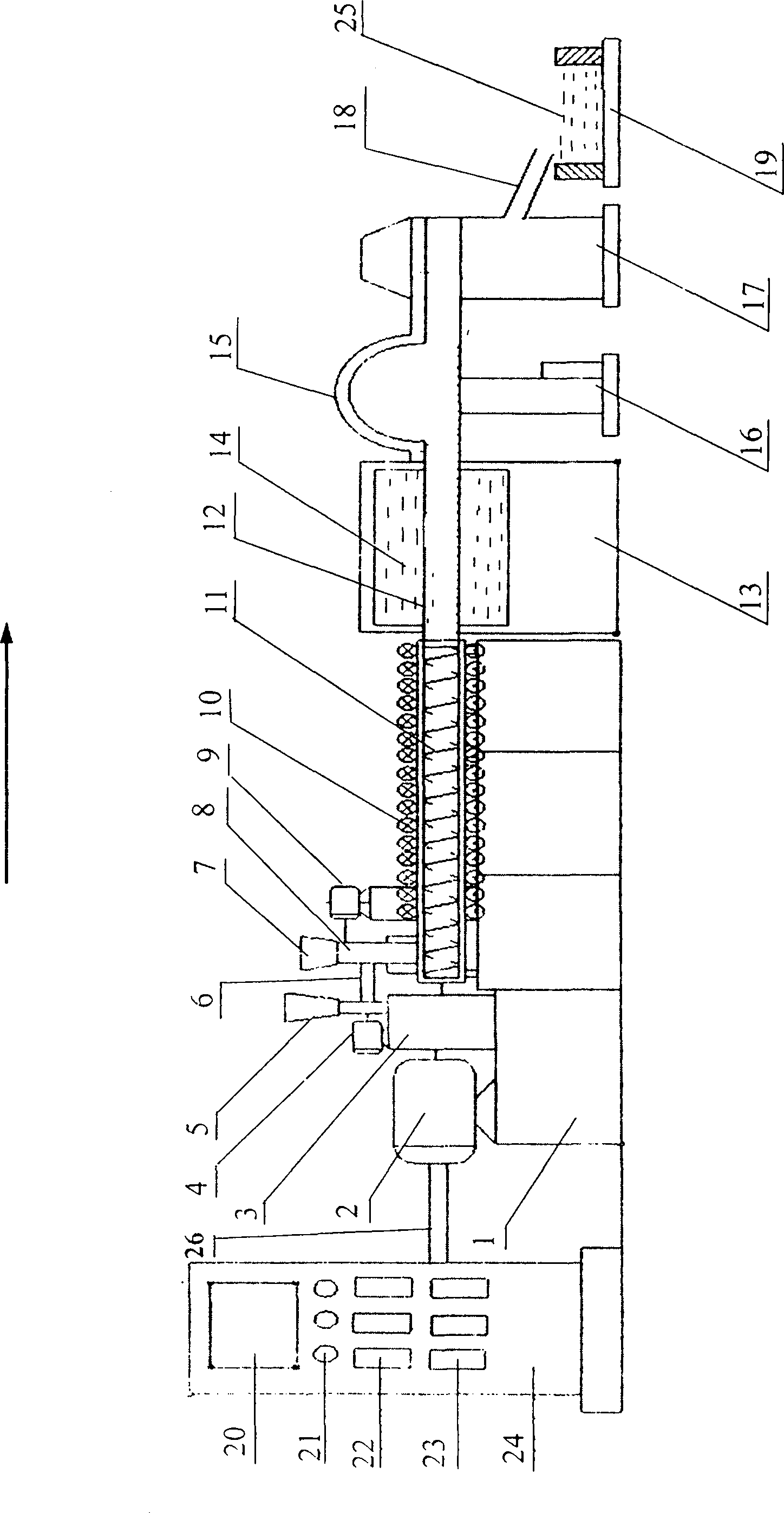

[0060] figure 1 As shown in the figure, it is the preparation state diagram of nickel-loaded multi-walled carbon nanotubes oriented arrangement. The preparation is carried out on a magnetic extruder.

[0061] The amount of chemical substances used in the preparation is determined according to a preset range, with grams and milliliters as measurement units.

[0062] The upper left part of the magnetic extruder base 1 is provided with a variable speed motor 2, the variable speed motor 2 is connected to the gearbox 3, the gearbox 3 is connected to the extrusion screw sleeve 11, and the right outer part of the extrusion screw sleeve 11 is connected to the cooling pipe 12, the cooling pipe 12 is placed in the cooling box 13, cooling water 14 is arranged in the cooling box 13, the cooling pipe 12 is connected with the drying box 15, and is driven by the drying motor 16, the dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com