Method for preparing orientated-state polylactic acid profile

A technology of polylactic acid and orientation, which is applied in the direction of coating, etc., can solve the problems of strict requirements on the purity of polylactic acid, difficult control of rolling mill line pressure and air nozzle, and complicated actual operation, so as to overcome unsatisfactory mechanical properties, excellent mechanical properties, The effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

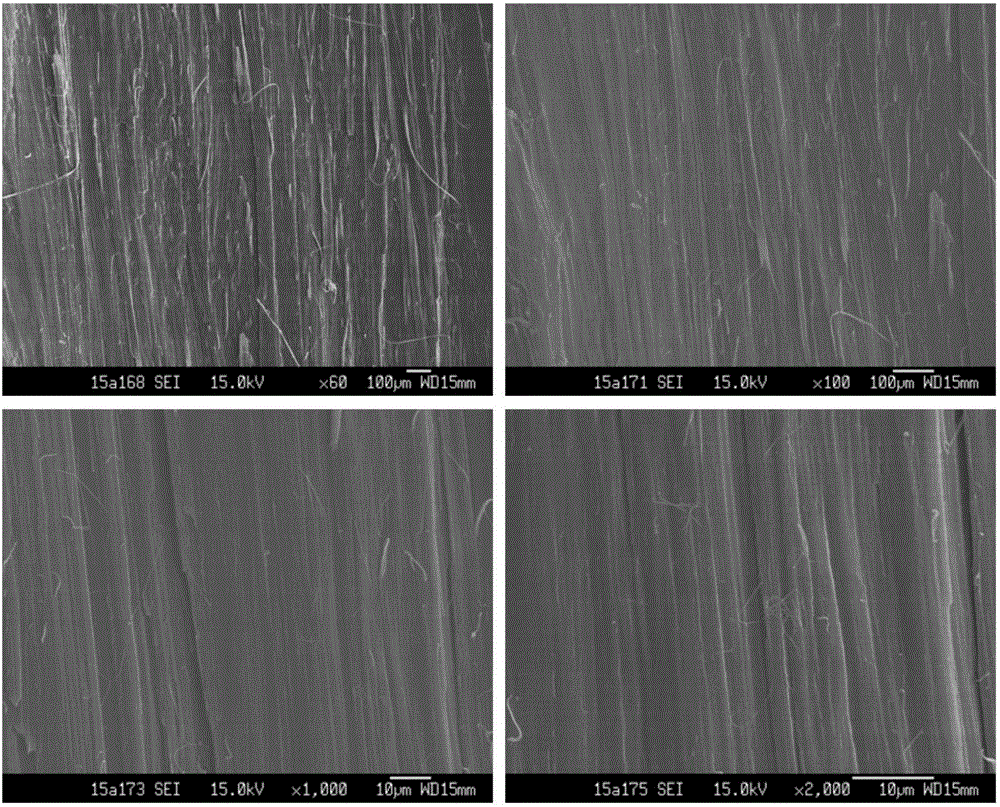

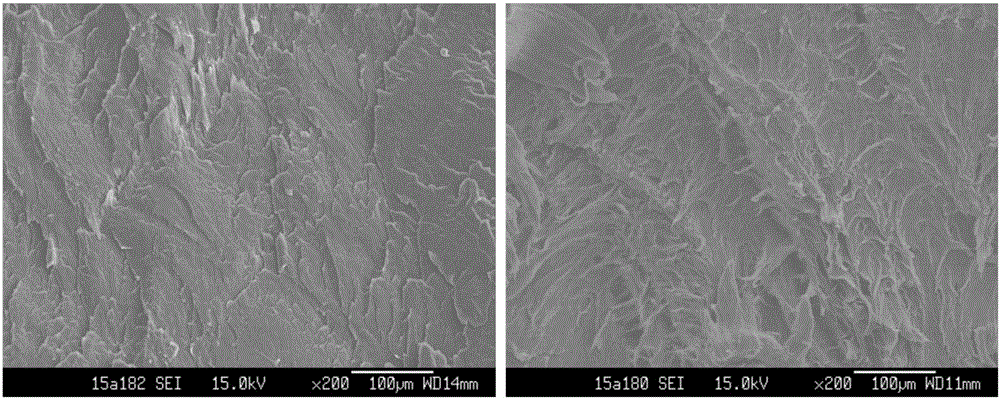

Image

Examples

Embodiment A

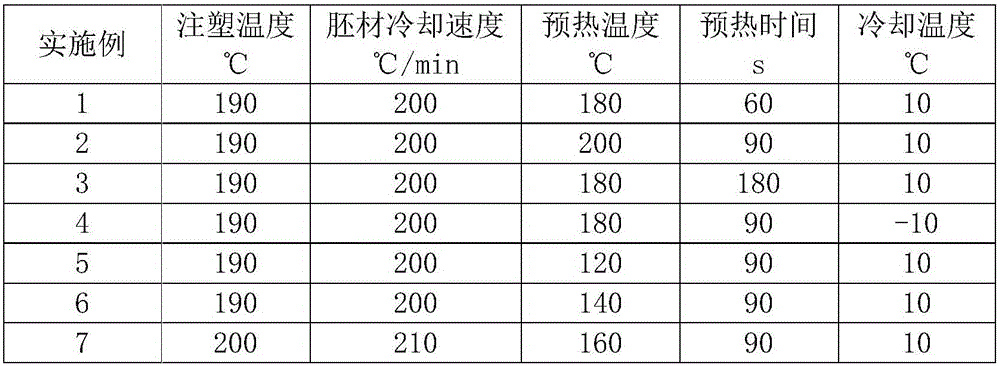

[0027] A method for preparing oriented polylactic acid profile, according to the following steps:

[0028] [1]. Vacuum-dry the L-polylactic acid fully before use.

[0029] [2]. After setting all the parameters of the injection molding machine, preheat it; after the preheating is completed, add the dried polylactic acid to start the injection molding process.

[0030] [3]. After demoulding, the injection-molded blank is rapidly cooled by a special cooling system to make a polylactic acid blank.

[0031] [4]. Heat the extrusion mold to 180°C. After stabilization, put the embryo into the cavity of the mold and heat for 2 minutes.

[0032] [5]. After the heating is completed, start the equipment to extrude the blank material into the molding cavity preheated to 120°C to prepare polylactic acid profiles in an oriented state.

[0033] [6]. After the extrusion is completed, the polylactic acid profile is rapidly cooled and quenched together with the molding cavity to obtain the fin...

Embodiment B

[0042] A method for preparing oriented polylactic acid profile, according to the following steps:

[0043] [1]. L-polylactic acid with a crystallinity of 8.5% is placed in a vacuum environment and fully dried before use.

[0044] [2]. Heat the embryo material processing mold to 200°C and keep the temperature constant. After the preheating is completed, put the polylactic acid particles into the mold and heat up and pressurize in a vacuum environment.

[0045] [3]. After the polylactic acid is heated in the mold for 3 minutes, forging is carried out. The forging pressure is 10 MPa and the time is 3 minutes to form a blank.

[0046] [4]. Heat the polylactic acid profile forming mold to 180°C and keep the temperature constant, then put the embryo into the mold and heat for 3 minutes.

[0047] [5]. After the heating is completed, start the equipment for forging, the forging pressure is 15MPa, and keep the pressure for 20s.

[0048] [6]. After the pressure holding is completed, q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com