A preparation method of rare earth-cobalt permanent magnet particles with high remanence ratio

A technology of remanence ratio and rare earth, applied in the direction of magnetic materials, magnetic objects, inorganic material magnetism, etc., can solve the problems of not considering the remanence ratio of alloy particles, destroying crystallographic anisotropy, and low remanence ratio of alloy particles, etc. Achieve excellent comprehensive performance, reduce oxygen content and high coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

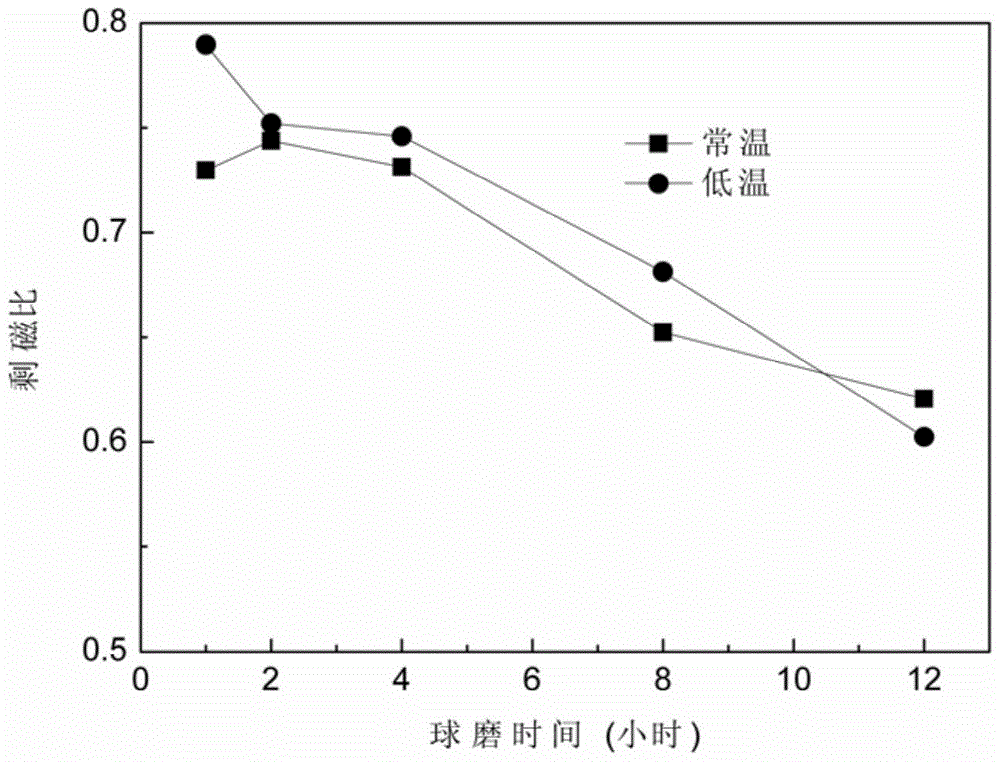

[0032] In this embodiment, the raw materials, selected ball mill, ball milling tank, organic solvent and dosage, ball size and ball-to-material ratio, and the sealing method of the ball milling tank are exactly the same as those of Comparative Example 1 above. The difference is that SmCo is prepared by low temperature ball milling. 5 Granules, prepared as follows:

[0033] After the ball mill jar is sealed well, perform the following operations to achieve low-temperature ball milling:

[0034] (1) is identical with the step (1) in the comparative example;

[0035] (2) Place the ball milling tank with raw materials, balls and organic solvents in liquid nitrogen for low-temperature cooling, take it out after the temperature of the ball milling tank is lower than -150°C, and install it on a ball mill for 5 minutes at normal temperature;

[0036] (3) Set the ball milling time, repeat step (2), until the total ball milling time reaches the set ball milling time, take off the ball...

Embodiment 2

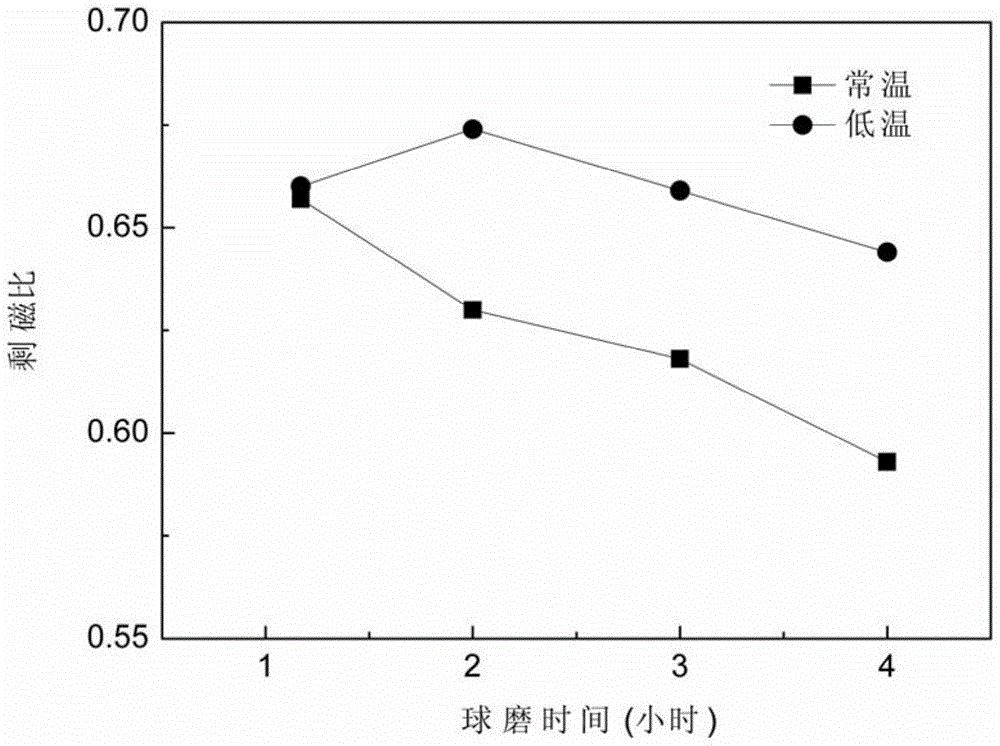

[0049] In this embodiment, the raw material is exactly the same as that of Comparative Example 2.

[0050] The raw material was prepared as SmCo by wet ball milling 5 The preparation method of the particles is basically the same as that in Example 1, except that in step (1), the ball-to-material ratio used is 8:1, and in step (2), the ball milling time is 4 minutes.

[0051] The ball milling product obtained in above-mentioned comparative example 2 and embodiment 2 is tested as follows:

[0052] (1) The ball milling product samples obtained in the above comparative example 2 and embodiment 2 are compared, the ball milling products are all suspended particles, and the lower particles are SmCo 5 Micron level, dense and precipitated at the bottom of the bottle, while the upper layer of particles is SmCo 5 Nanometer level, suspended in an organic solvent, the yield of nanoparticles milled at low temperature in Example 2 is significantly higher than that of nanoparticles milled a...

Embodiment 3

[0064] In this embodiment, the raw materials, the selected ball mill, the ball milling tank, the organic solvent and its dosage, the surfactant and its dosage, the ball size and the ball-to-material ratio, and the sealing method of the ball milling tank are exactly the same as those of Comparative Example 3 above. The difference is that PrCo is prepared by low temperature ball milling. 5 Granules, prepared as follows:

[0065] After the ball mill jar is sealed well, perform the following operations to achieve low-temperature ball milling:

[0066] (1) is identical with the step (1) in the comparative example;

[0067] (2) Place the ball mill tank containing raw materials, grinding balls, surfactants, and organic solvents in liquid nitrogen for low-temperature cooling, take it out after the temperature of the ball mill tank is kept below -90°C, and install it on the ball mill at room temperature Ball mill for 3 minutes;

[0068] (3) Set the ball milling time, repeat step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com