Pulsing type dust-free non-discharge-water boiler cinder flushing system

A non-emission, pulse-type technology, applied in the direction of filtration separation, conveyor, separation method, etc., can solve the problems of air pollution, dust, water pollution, etc., and achieve the effect of reducing dust and improving the surrounding environment of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

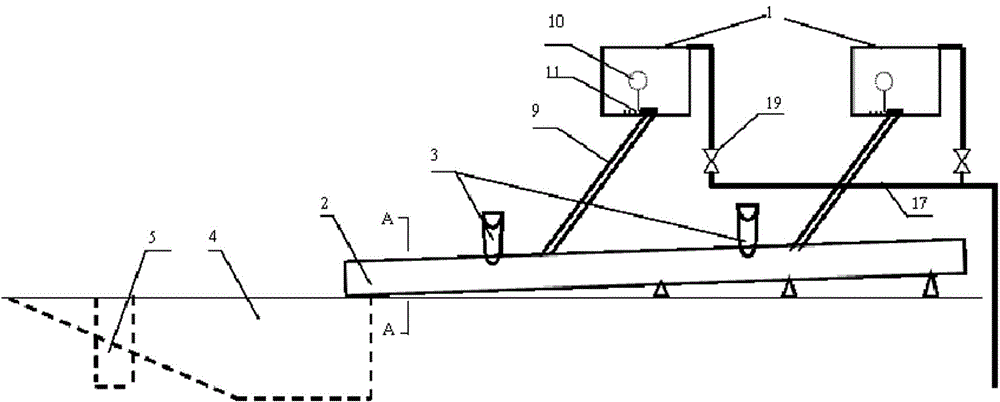

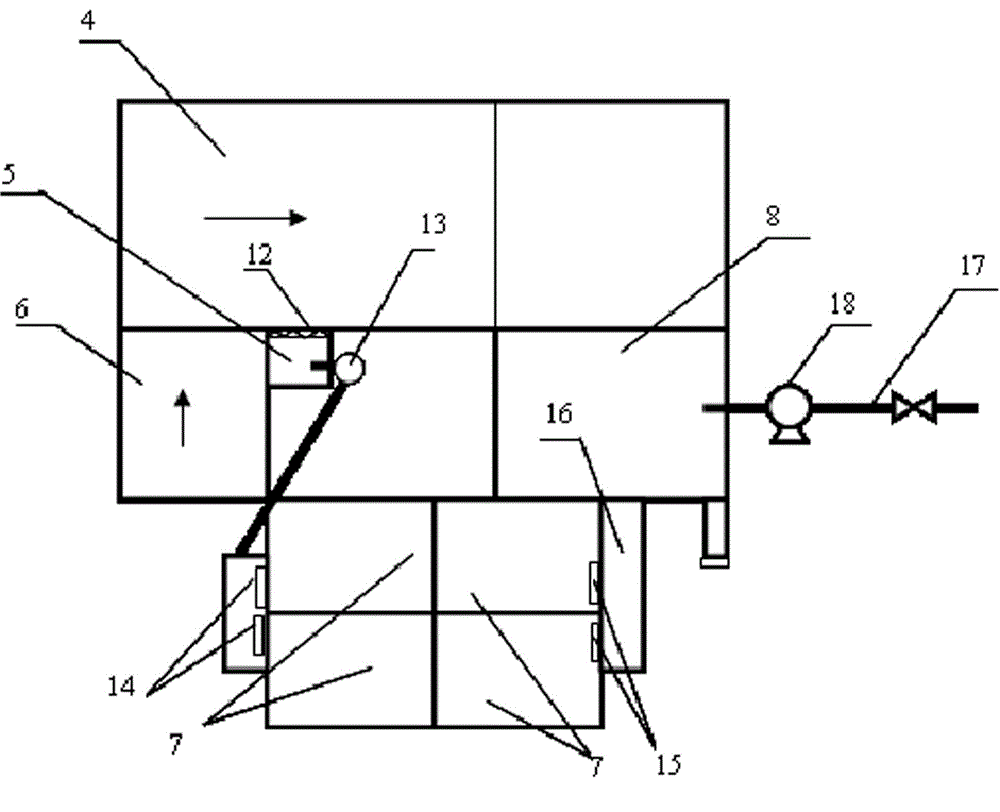

[0016] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a pulse-type dust-free and non-discharging water boiler slag flushing system, which consists of an energy storage water tank 1, a slag falling tank 2, a chute 3, a slag pool 4, a sewage well 5, a filter tank 6, and a sedimentation tank 7 It is composed of several parts such as clear water pool 8.

[0017] Wherein, the energy storage water tank 1 is arranged above the slag tank 2 , and is connected to the slag tank 2 through a sewer pipe 9 . A floating ball 10 and a valve plate 11 for controlling the water outlet thereof are arranged in the energy storage water tank 1 .

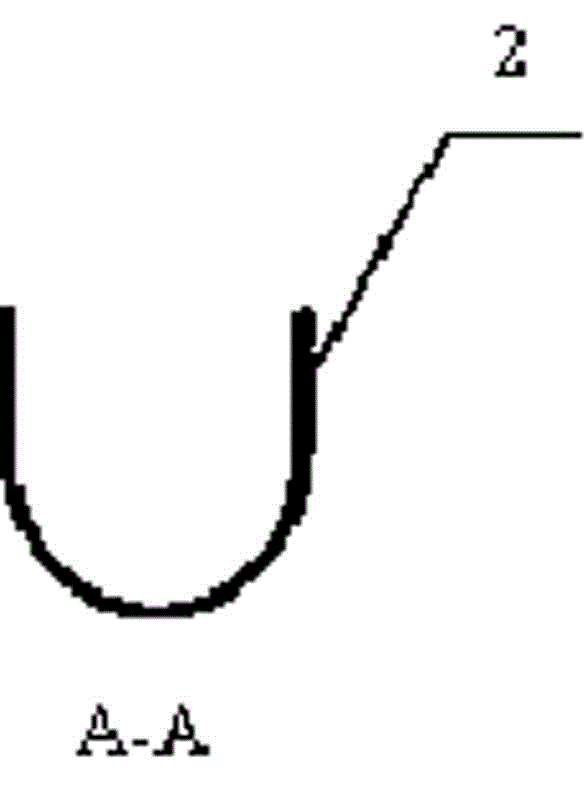

[0018] The slag tank 2 has a U-shaped structure, which is connected with the chute 3 .

[0019] The slag pool 4 is located at the bottom of one end of the slag tank 2, and the sewage well 5 is provided at the bottom. A filter screen 12 is provided between the slag pool 4 and the sewage well 5 .

[0020] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com