Method and equipment for producing aluminum pigment having metal effect

A technology of aluminum pigment and effect, applied in the direction of fibrous filler, dyeing physical treatment, etc., can solve the problems of over-grinding of coarse particles, failure of fine particles to form flakes, insufficient concentration of aluminum pigment particle size distribution, etc., and achieve the effect of strong metal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

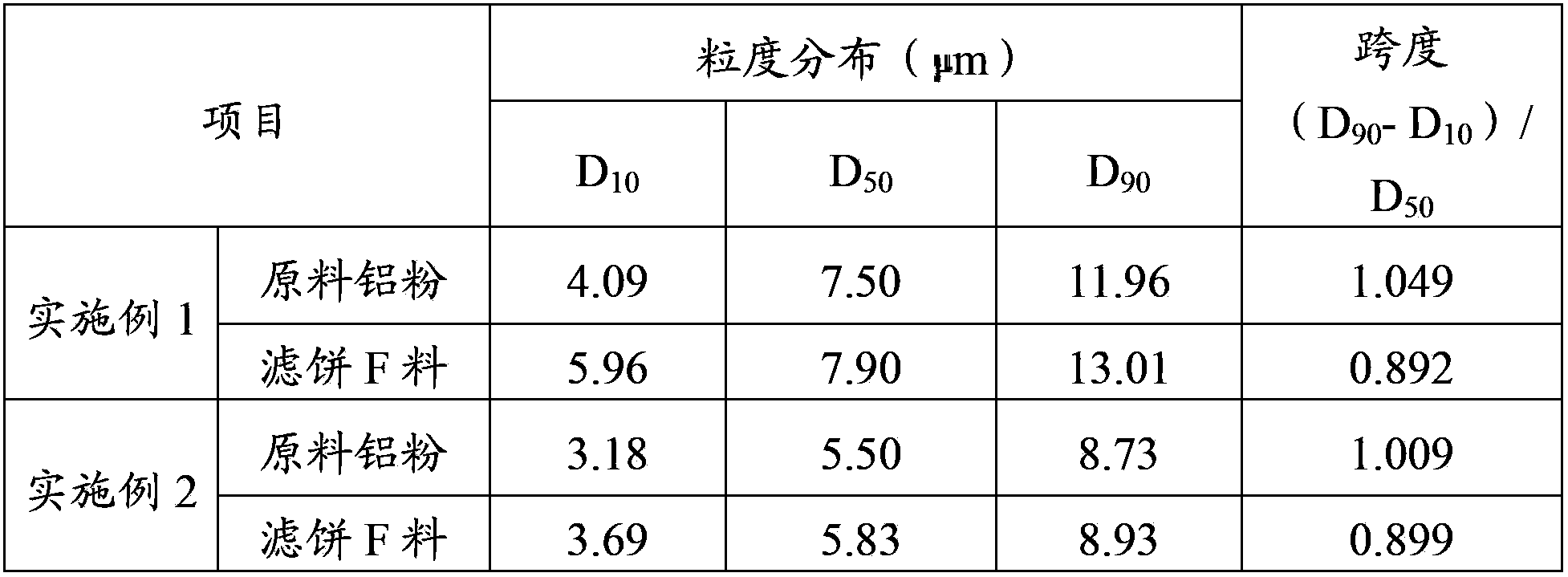

[0029] a.D 50 100kg of nitrogen atomized fine spherical aluminum powder of 7.5μm, add D 80 Solvent oil 1900kg, oleic acid 2.0kg, stir evenly. The above-mentioned materials are classified using, for example, a hydrocyclone with a diameter of 10 mm. Grading pressure control is 0.3-0.5mpa. The overflow material is filtered by the filter press and dried, the filter cake is A material, and the filtrate is reused; the grit material is filtered by the filter press, blown dry, the filter cake is B material, and the filtrate is reused.

[0030] b. Make material B into a mixture of aluminum powder: solvent oil = 5:95 (weight ratio). Mix well with a mixer. Use a hydrocyclone with a diameter of 25mm for classification. Grading treatment pressure control is 0.3-0.5mpa. The overflow material is filtered by the filter press, blown dry, the filter cake is C material, and the filtrate is reused; the grit material is filtered by the filter press, blown dry, the filter cake is D material, ...

Embodiment 2

[0037] Same as Example 1, except that the fine spherical aluminum powder atomized by nitrogen gas is different, and the data are shown in Tables 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com