Grain refinement machining process of hard aluminium alloy cast ingot

A hard aluminum alloy and processing technology, applied in the field of metal processing, can solve problems such as increasing cooling strength, and achieve the effects of refining as-cast grains, improving fatigue resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The fine-grain refinement processing technology of the hard aluminum alloy ingot of the present invention comprises the following steps;

[0019] (1) Dosing first: the base of the alloy is made of 99.85 grade aluminum ingot, and Mg and Zn elements are added in the form of pure metals. Considering that Cu, Cr, Ti, and Zr elements have high melting points and low content in the alloy, the middle added in the form of an alloy;

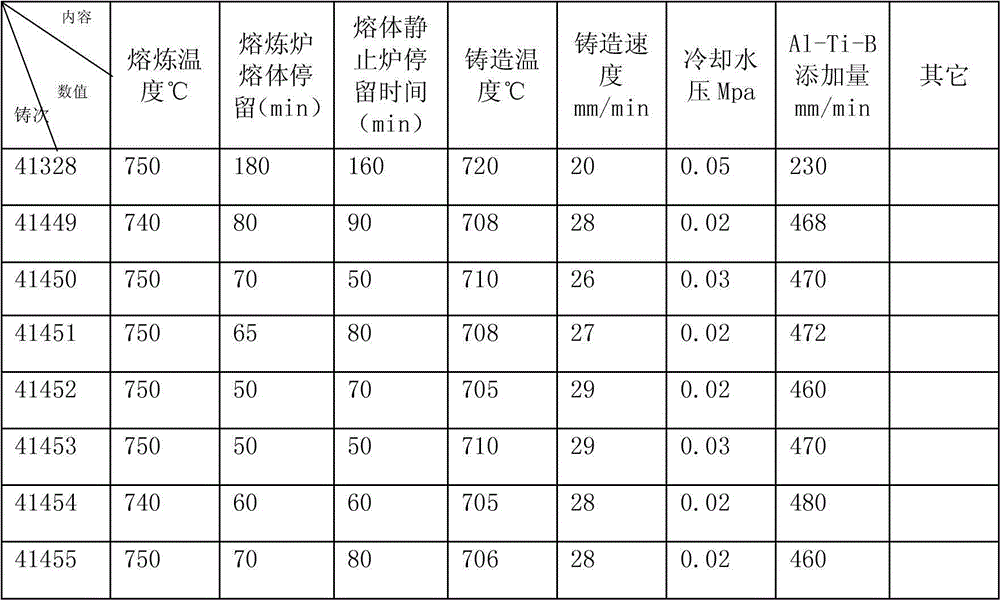

[0020] (2) Afterwards, the regenerative gas furnace is used for melting, the melting temperature does not exceed 750°C, and the residence time of the melt in the melting furnace does not exceed 2 hours;

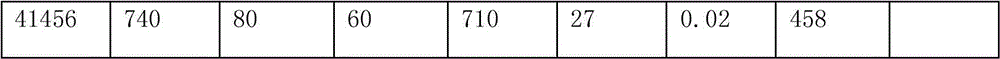

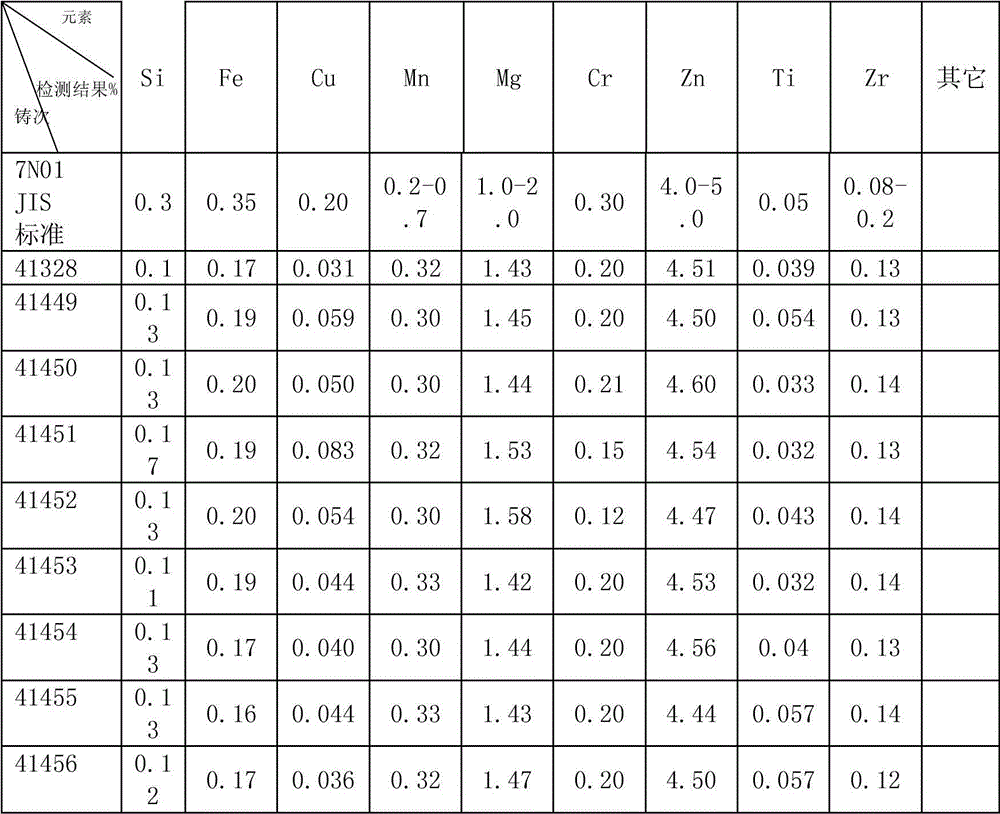

[0021] (3) In the smelting process, after the chemical composition and temperature have been adjusted by sampling and analysis, the furnace must be poured as soon as possible. The mass percentage of Si is controlled at 0.12%, the mass percentage of Fe is controlled at 0.18%, and the mass percentage of Mg is controlled at 0.18%. The content is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com