Loess foundation pit supporting method

A foundation pit support and loess technology, which is applied in soil protection, excavation, infrastructure engineering, etc., can solve the problems of excessive grading and excavation, poor drainage, and impact, and solve the problem of construction site occupation. , processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with specific embodiments.

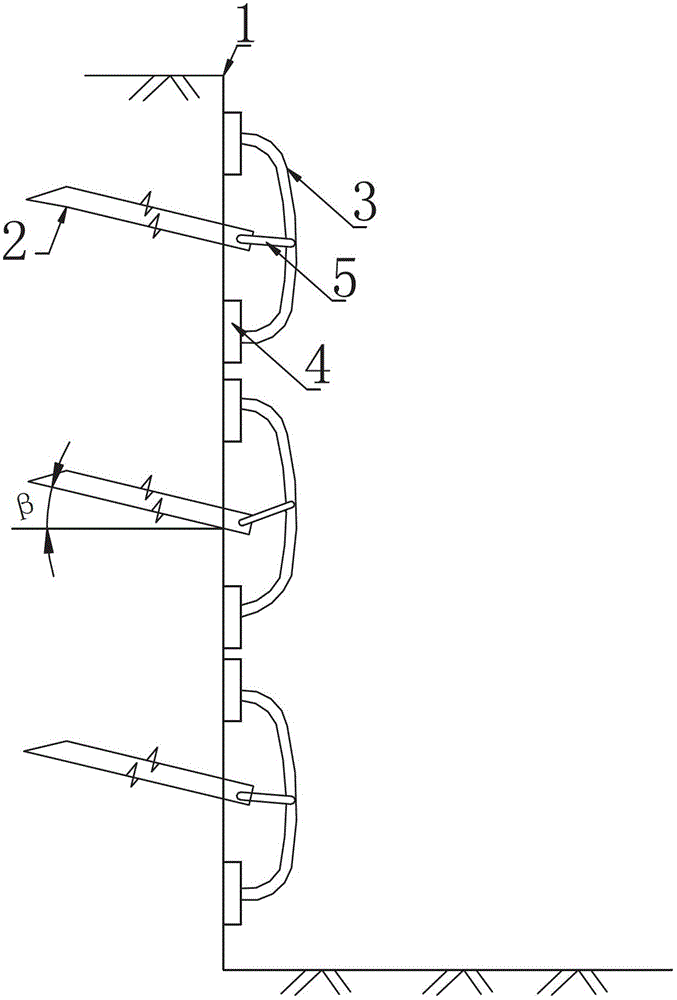

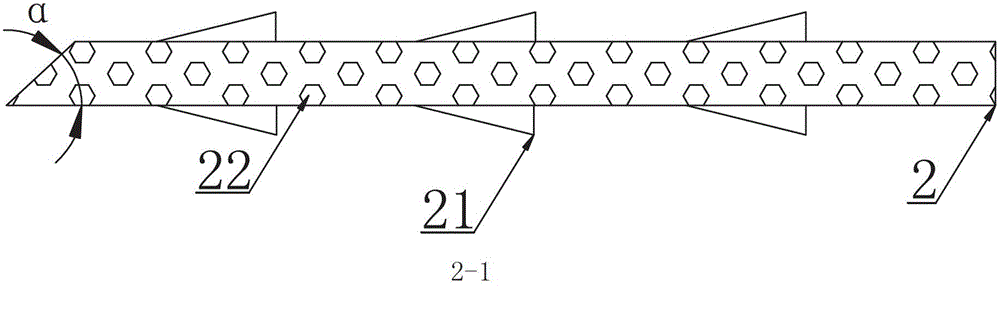

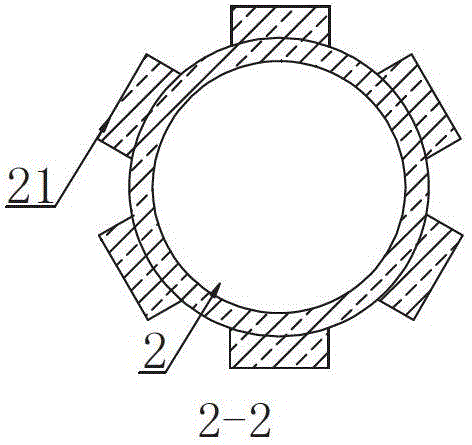

[0033] refer to figure 1 , on the side wall 1 that needs to be supported in the foundation pit, insert the drainage pulling pipe 2 at a certain inclination angle β=5-10°, the length of the drainage pulling pipe 2 left outside the side wall 1 is 20-30cm, and operate when connecting convenient. The density of the drainage pulling pipe 2 on the side wall is determined according to the size of the bow support 3, the upper and lower spacing is 2-4 m, and the horizontal spacing is 4 m. The tie rod 5 is fixedly connected to the top of the drainage pull pipe 2 through the connecting hole 31 at the midpoint of the bow 3 , and both ends of the bow 3 are in contact with the supporting side wall 1 through the support plate 4 . refer to Figure 4 , the pull rod 5 is a rigid part with a diameter of 1-2 cm. There is an adjustable screw rod 51 in the middle of the pull rod 5. The leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com