Device for measuring dynamic change of friction static electricity and friction property of insulating material

A tribostatic and frictional performance technology, applied in measuring devices, measuring electrical variables, using electrical devices, etc., can solve problems such as no measurement of tribostatic voltage or electrostatic charge, low friction coefficient and wear rate, and incompetent tribostatic mechanism. , to achieve a wide measurement range, overcome cumulative drift, and select a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

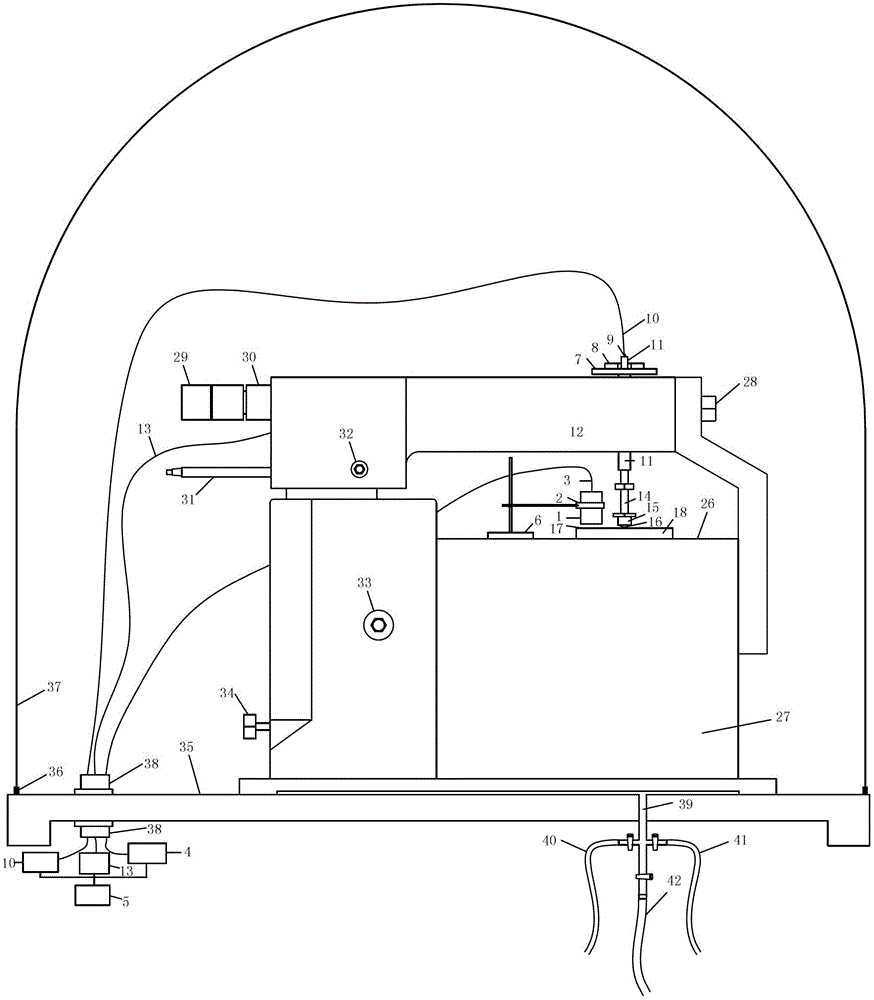

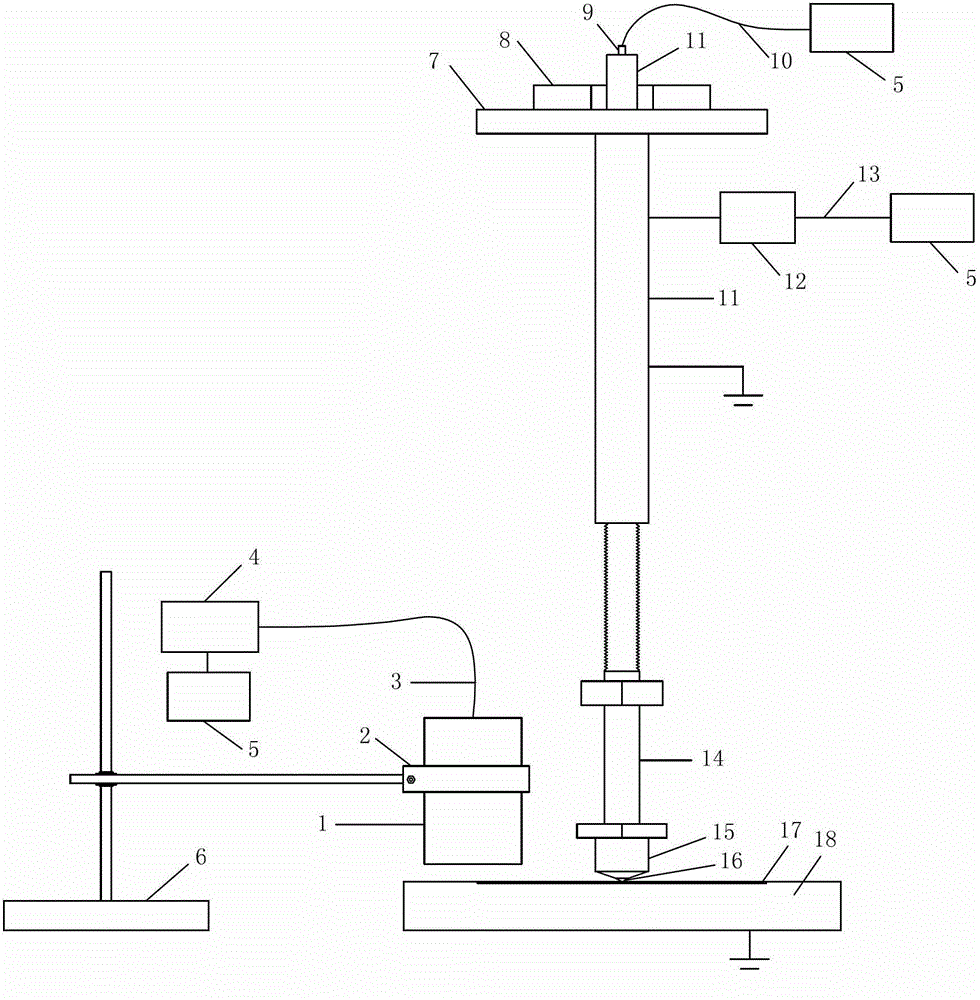

[0033] Such as figure 1 and figure 2 As shown, in this example, the electrostatic potential induction head 1 of the vibrating capacitive electrometer 4 is placed horizontally on the horizontally rotating friction and wear testing machine 27, and the electrostatic potential induction head 1 is adjusted at will by the clamp 2 installed on the openable magnetic table base 6. The distance between the head 1 and the working platform 26 of the friction and wear testing machine, the signal obtained by the electrostatic potential induction head 1 is input into the computer through the transmission line 3 and converted by the A / D data acquisition card 5, and the electrostatic potential signal is processed by software to obtain Excel files, Word documents and JPEG pictures.

[0034] The measurement range of the vibrating capacitive electrometer 4 is 0 to ±1999V, the display resolution is ±1 / 2000, the minimum display resolution can reach 1V, and the accuracy is better than 2% of readin...

Embodiment 2

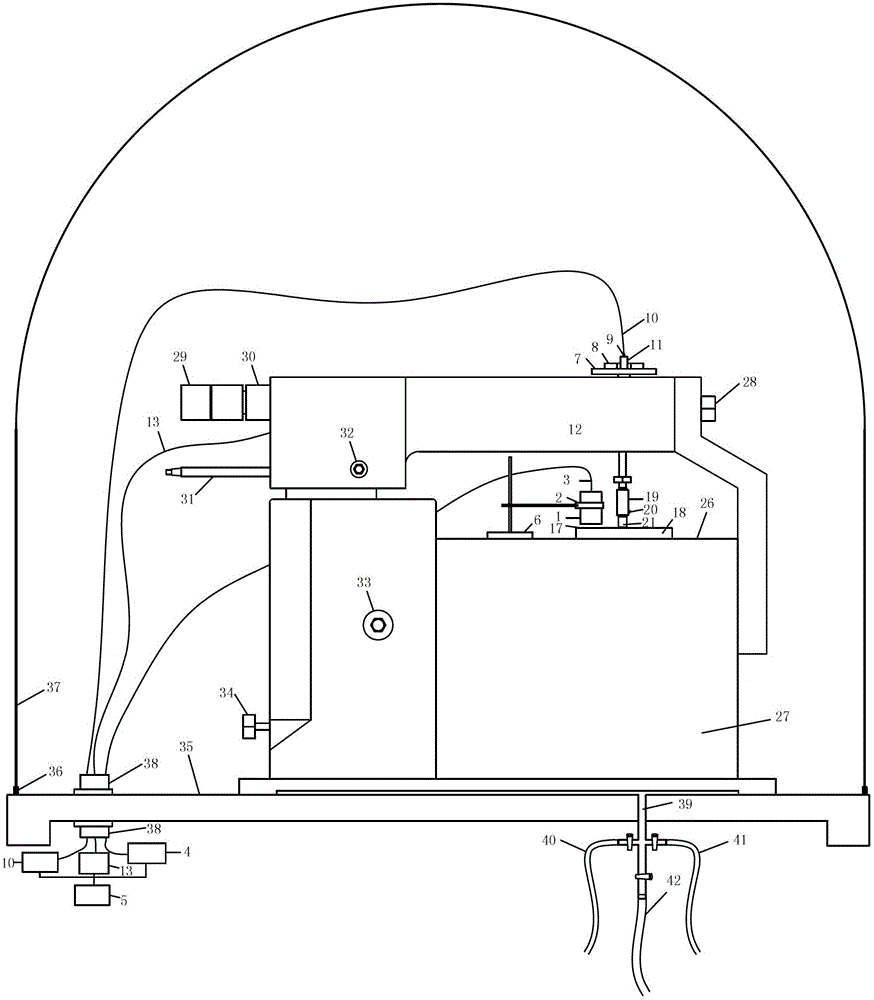

[0067] Such as image 3 and Figure 4 As shown, in this example, through the disassembly and conversion of the fixture, the ball-pack point contact sliding friction form can be changed to the pin-disk surface contact sliding friction form.

[0068] ball-pack contact sliding friction form (see Figure 4 ), in this example, by disassembling the fixed sleeve rod 14 and the steel ball fixture 15 and replacing them with a steel bolt fixture (inserted thermocouple) 19, the ball-package contact sliding friction form can be changed to the bolt-disk surface contact sliding friction form. One end of the steel bolt 21 processed into a tapered surface is inserted into the steel bolt fixture 19, and the steel bolt 21 is pressed and fixed by the first fastening nut 20 on the steel bolt fixture, and the steel bolt fixture 19 and the loading sleeve rod 11 are connected by threads . The thermocouple 9 is inserted into the hollow loading sleeve rod 11 up to the upper surface of the steel bol...

Embodiment 3

[0072] Such as Figure 5 , Figure 6 , In this example, the form of sliding friction can be changed to the form of rolling friction through the removal and conversion of the fixture. Figure 6 Is the ball bearing - disk wire contact rolling friction form, such as Figure 5 , Figure 6 As shown, in this example, the fixed sleeve rod (inserted thermocouple) 14 and the steel ball clamp 15 or the steel bolt clamp (interpolated thermocouple) 19 are disassembled and replaced with the cage clamp 22, the second fastening nut 23 and the ball The bearing cage 24 can change the form of sliding friction into the form of ball bearing-disc line contact rolling friction. Install the ball bearing 25 in the ball bearing cage 24, then fix the cage 24 and the cage clamp 22 with the second fastening nut 23, and then install the cage clamp 22 on the loading sleeve rod 11. Insert the thermocouple 9 into the center shaft of the ball bearing 25 to measure the temperature change of the ball bearin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com