Variable-displacement compressor

A compressor and capacity technology, which is applied in the direction of liquid variable capacity machinery, variable capacity pump components, mechanical equipment, etc., can solve the problems of reduced durability of rubber material components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

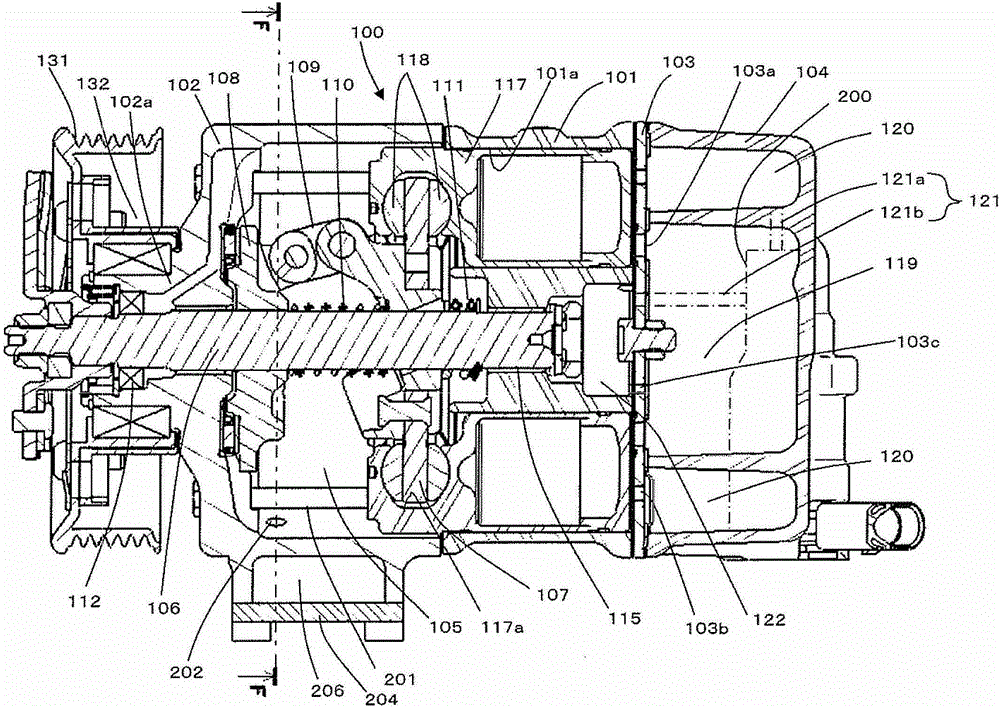

[0033] Figure 1 ~ Figure 4 It is a longitudinal sectional view showing a variable capacity compressor to which the present invention is applied.

[0034] The variable capacity compressor 100 used in the vehicle air conditioner includes: a cylinder block 101 having a plurality of (six in this embodiment) cylinders 101a around the outside of the central axis; 102; and the rear shell 104 which is arranged on the other end of the cylinder body 101 through the valve plate 103.

[0035] The front case 102, the cylinder block 101, the valve plate 103, and the rear case 104 constituting these cylindrical storage members are fastened to each other by a plurality of (six in this embodiment) through bolts 201 penetrating the peripheral portions of the members.

[0036] A drive shaft 106 is provided so as to traverse the inside of the crank chamber (inner space of the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com