High-temperature alloy elastic seal piece processing technique and mould thereof

A technology of elastic seals and processing technology, applied in the field of sheet metal stamping, can solve the problems of difficulty in assembly of parts, difficulty in manufacturing, difficulty in processing, etc., and achieve the effects of perfect process technology, convenient production and operation, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

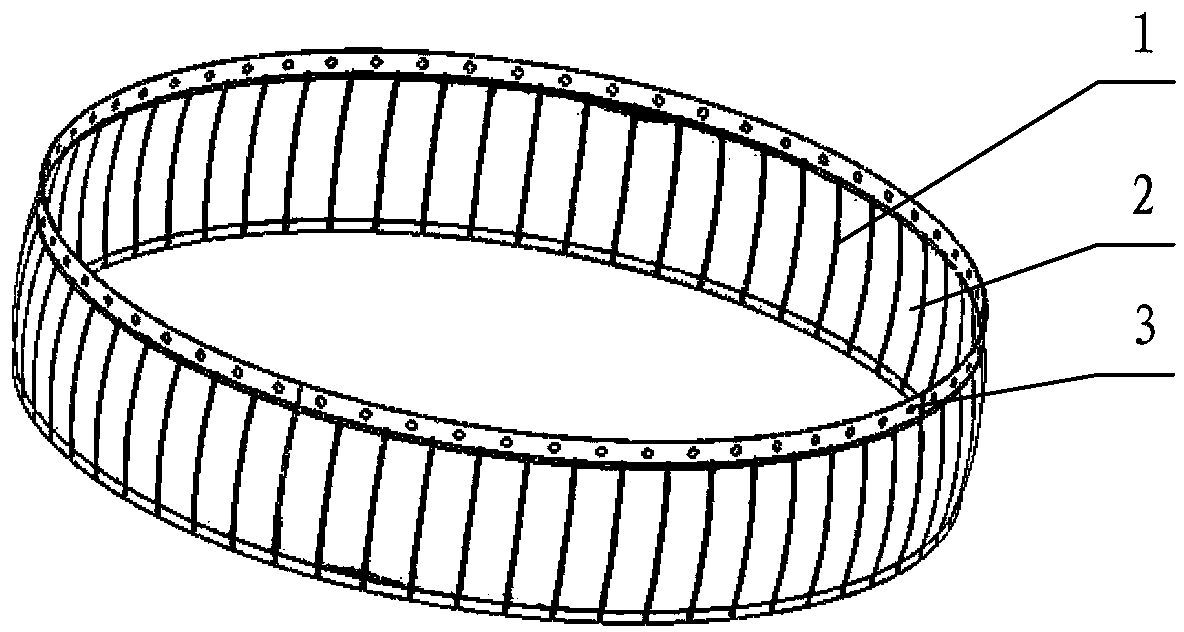

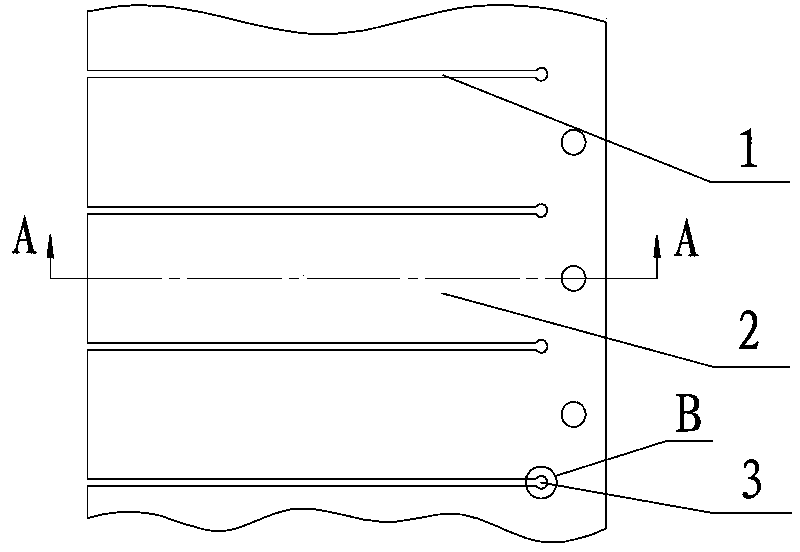

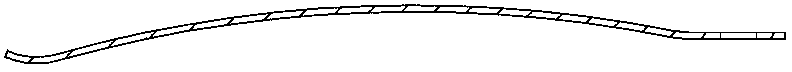

[0034] Such as figure 2 , image 3 , Figure 4 As shown, taking the elastic seal of a gas turbine runner bushing as an example, its structural feature is that dozens of plug welding holes 3 and telescopic grooves 1 are evenly distributed in the circumferential direction of the elastic seal, and the size and position of the holes and grooves are strictly required. , to ensure the accuracy of its relative position is a key technology in the processing of this part; in addition, the material of the part is high-temperature alloy spring steel, which has a large amount of springback, and the longitudinal section of the part is three sections of arcs and one section of straight line. It is another key technology in the process of processing the part to ensure that the contour shape of the part after forming is the same as that required b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com