Connecting structure and connection processing process of web plates of ferry glass reinforced plastic boat

A connection structure, fiberglass technology, applied in the direction of ships, hulls, ship weapons, etc., can solve the problems of angle material corner breakage, bottom plate or web plate and angle material disengagement, it is difficult to withstand high-frequency alternating loads, etc., to achieve resistance Improved tensile load capacity, easy construction, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

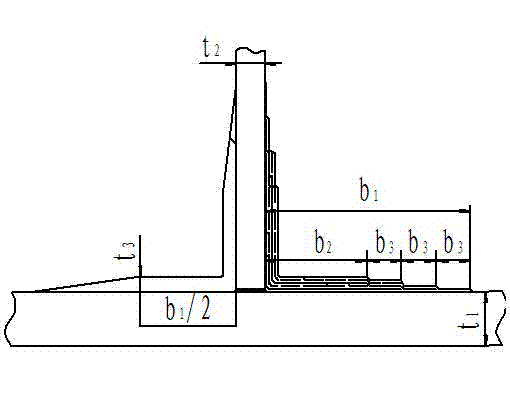

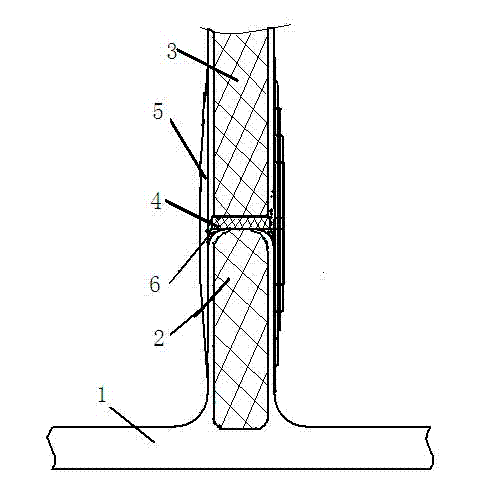

[0020] As shown in the figure, a connection structure of a fiberglass boat web is characterized in that a fiberglass bottom plate 1 with a lower web 2 is provided, the lower web 2 is perpendicular to the bottom plate 1, and an upper web 3 is arranged above the lower web 2, There is a plastic foam cushion 4 between the upper web 3 and the lower web 2, and the upper web 3 and the lower web 2 are connected by connecting plates 5 on both sides. The glass fiber reinforced plastic bottom plate 1, lower web 2 and upper web 3 are generally prefabricated parts, to improve production efficiency, the upper web 3 can be a plastic foam sandwich board, that is, a glass fiber reinforced plastic protective layer is pasted on the plastic foam core board, so that it has the advantages of light weight, good thermal insulation and sound insulation performance, and low cost. The gap be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com