Large plastic inspection well

A technology for plastic inspection wells and inspection ports, applied in the field of inspection wells, can solve the problems of water pollution inside or outside the pipeline, strength reduction, waste of clay resources, etc., and achieve the effects of shortening the construction period, strong earthquake resistance, and low construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

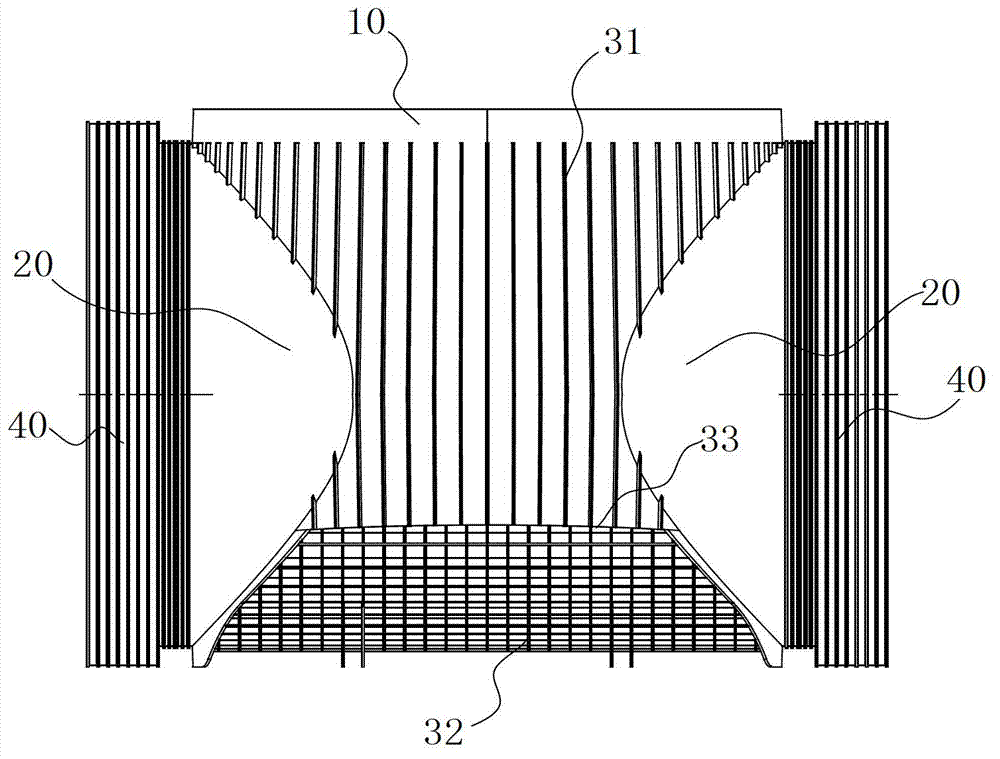

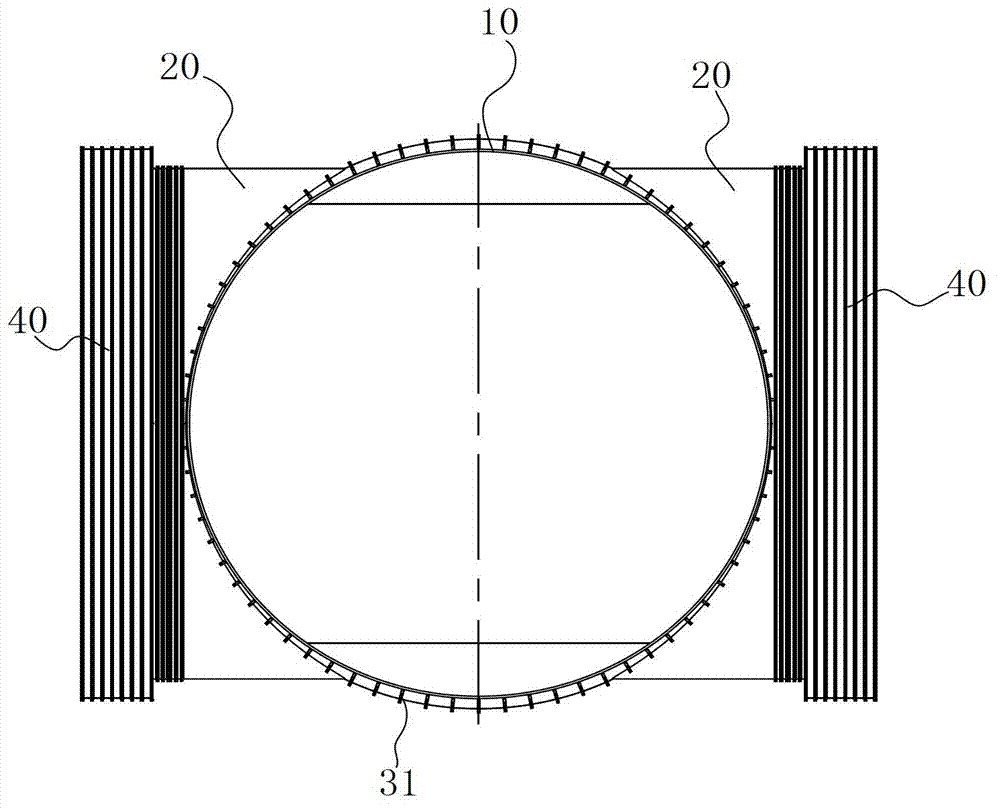

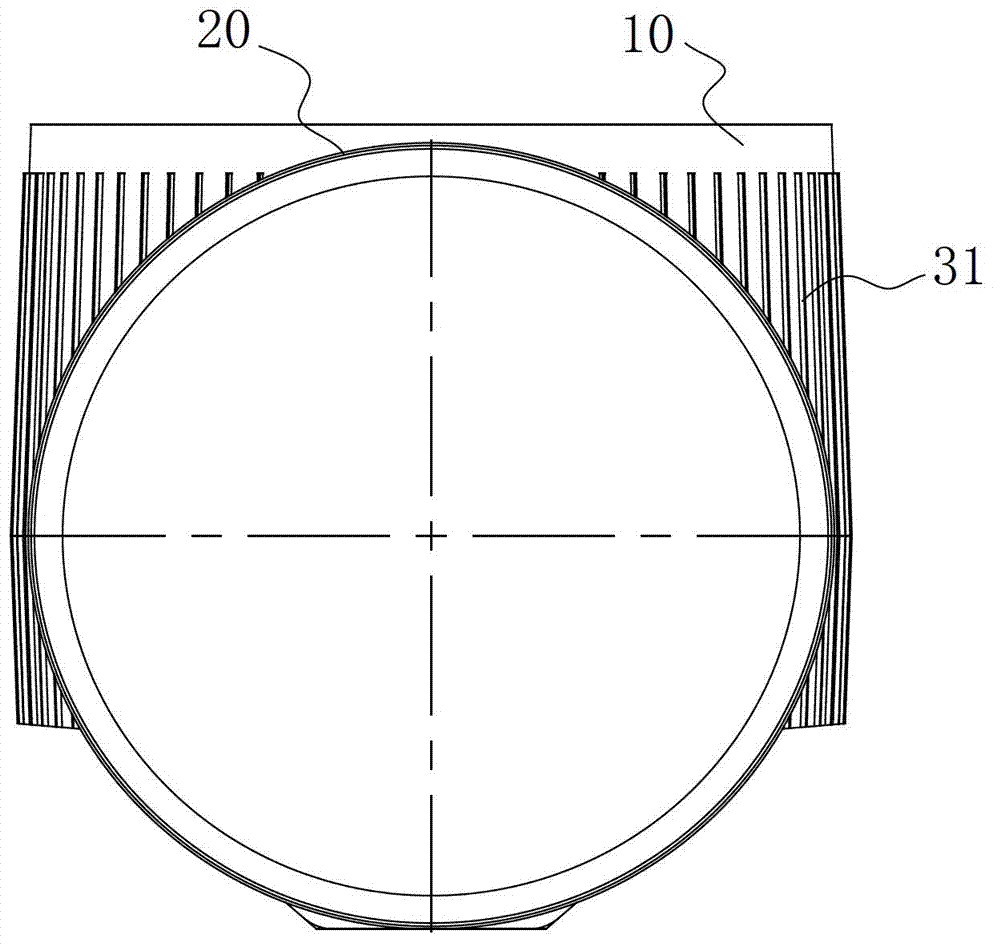

[0012] combine figure 1 , 2 . A plastic inspection well shown in 3 includes a body, which is integrally injection molded. The body includes an inspection port 10 for maintenance and a connecting port 20 connecting the pipe body. The inner cavity of the body between the inspection port 10 and the connecting port 20 is connected; in this way, the connecting port 20 is used to connect plastic pipes or metal pipes or concrete prefabricated Tube. The inspection port 10 and the nozzle port 20 are in the shape of a tube, and the body as a whole is in the shape of a plurality of intersecting tubes. Or it can also be that the whole body is in the shape of a square cube, and an inner cavity is arranged on it, and the inner cavity communicates with the inspection port 10 and the connecting port 20 . The inspection port 10 can be closed at ordinary times, and can be opened for personnel to enter for inspection and maintenance. The inspection port 10 is usually vertically upward, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com