Installation structure of small size veneer building materials

An installation structure and small-scale technology, which is applied in the direction of building structure, construction, covering/lining, etc., can solve the problems of high cost of finished product protection, difficult quality control, cross-contamination, etc., to improve construction quality and work efficiency, reduce Chance of cross-contamination, effect of reducing common quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

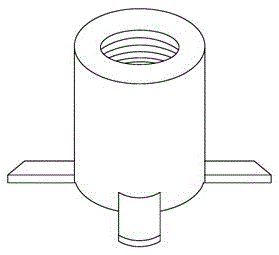

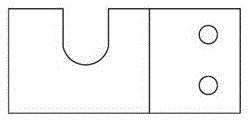

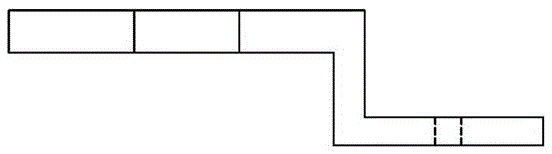

[0022] Example: such as Figure 1 to Figure 6 As shown, a small-sized veneer building material installation structure includes a veneer stone plate and a Z-shaped pendant 4. The veneer stone plate includes a small-size veneer stone 1, embedded nuts 2, bolts 3, and templates 5 Formwork 5 is provided with cement mortar 7, and embedded part nut 2 is arranged in cement mortar 7. Bolt 3 passes through formwork 5 from the back of formwork 5 and is threadedly connected with embedded part nut 2. The outside of cement mortar 7 is paved with several pieces of small specifications. The veneered stone 1 constitutes the overall outer surface of the veneered stone slab; the Z-shaped pendant 4 is fixed to the wall, and the Z-shaped pendant 4 has a notch for coupling with the bolt 3, and the veneered stone slab passes through the bolt 3 set on its back Hang on the Z-shaped pendant 4.

[0023] The cement mortar 7 is provided with a reinforcement net 6, the reinforcement net 6 is glass fiber o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com