Infrared marker for detecting heating of electric equipment

A live equipment, infrared technology, applied in the field of infrared marking, can solve the problems of the surface conditions of the heating parts of electrical equipment vary greatly, reduce the accuracy and efficiency of measurement, and cannot cover all phenomena, etc., to achieve easy detection range, convenient storage and reference, and improve monitoring efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will be described in conjunction with the accompanying drawings and specific embodiments.

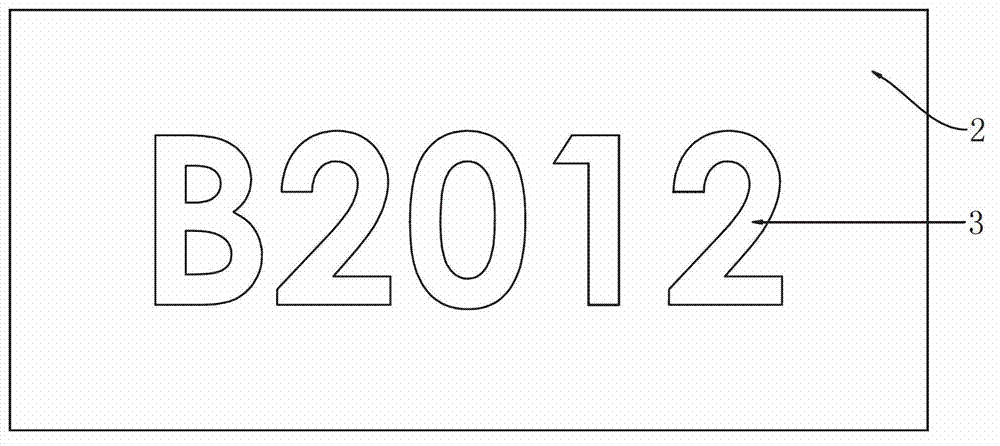

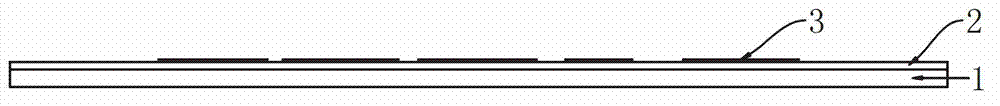

[0012] see figure 1 and figure 2 . The infrared marking used for heating detection of charged equipment described in the present invention has a structure as follows: an infrared material layer 2 is coated on a PET film 1, and an anodized aluminum foil mark 3 is also attached on the PET film 1, and the infrared material layer 2 and The anodized aluminum foil mark 3 is on the same side of the PET film 1 . The infrared material layer 2 is an infrared material layer with a matte gloss of 5-7 and a surface emissivity of not less than 0.95. Anodized aluminum foil mark 3 is an anodized aluminum foil text mark with a surface emissivity of 0.02. The text mark can be a letter number, a number number, or a combination of letters and numbers.

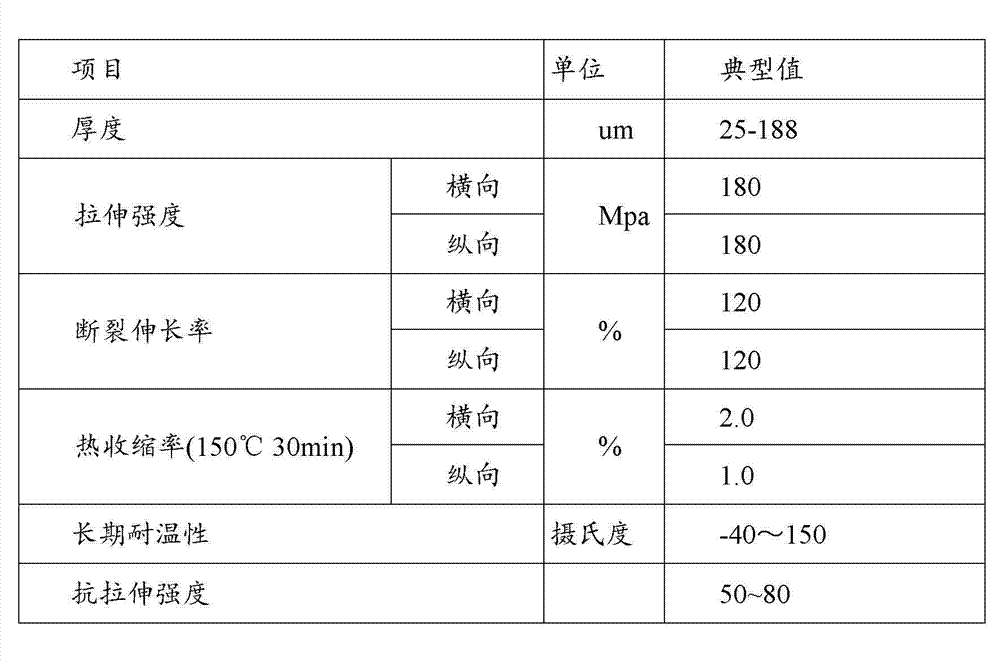

[0013] The emissivity of the PET film product used in the present invention is 0.87, and the emissivity is fixed at 0.95 after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com