Drying agent layer preparation method, OLED (organic light emitting diode) display screen and packaging method of display screen

A technology of light emitting diode and desiccant layer, which is applied in coating, vacuum evaporation plating, metal material coating process, etc., can solve the problem of high cost, and achieve the effect of improving packaging efficiency and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

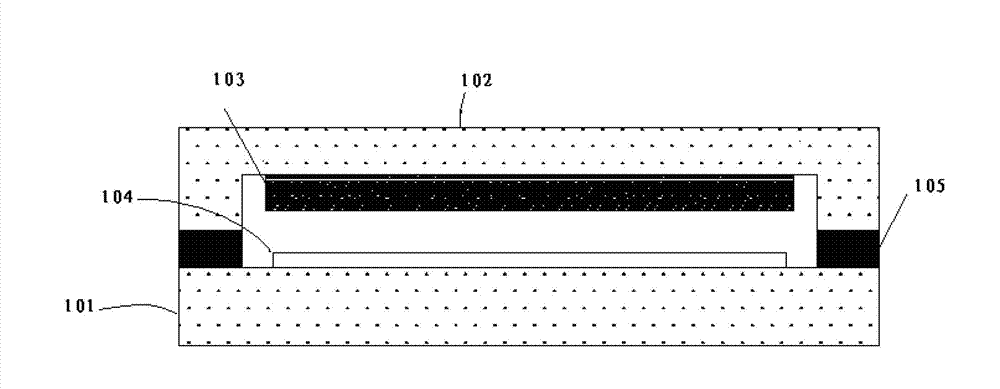

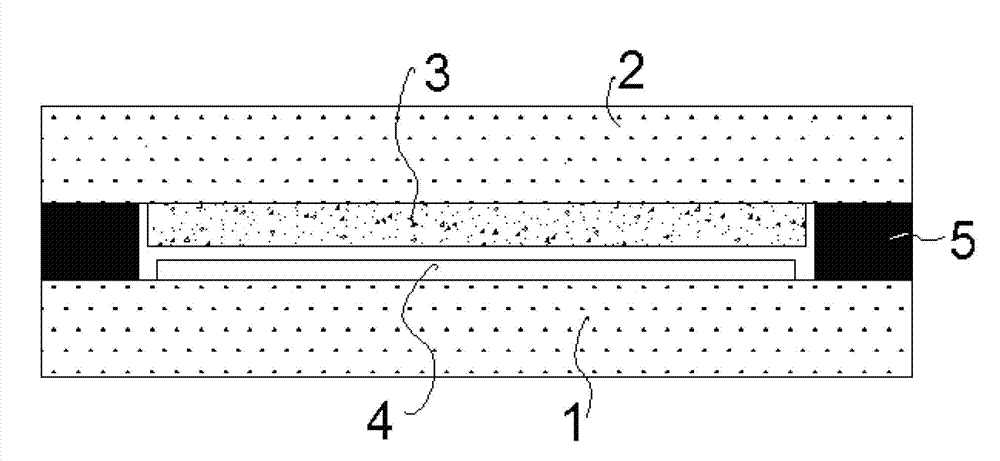

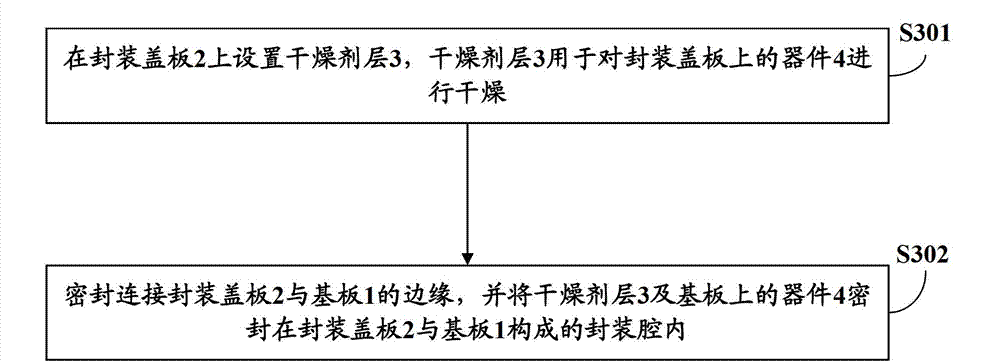

[0024] Embodiments of the present invention provide a method for preparing a desiccant layer, an organic light-emitting diode display screen and a packaging method thereof. A desiccant layer is provided on the packaging cover plate, and the desiccant layer can effectively absorb the infiltrated water and oxygen, and the packaging cover plate and The edge of the substrate is sealed and connected, and the desiccant layer and the device on the substrate are sealed in the sealed cavity. In the organic light-emitting diode display screen provided by the embodiment of the present invention, since the desiccant layer is used, and the desiccant layer can be directly arranged on the packaging cover plate, it is not necessary to use the traditional non-transparent sheet-shaped desiccant sheet and separate the desiccant sheet Layer by layer is attached to the groove of the packaging sheet, so there is no need to manufacture the packaging sheet with grooves, which improves the packaging ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com