Electric actuation of valve based on knowledge of closing time of valve

A technology of closing time and electric operation, which is applied in electrical control, engine control, fuel injection control, etc., can solve the problem of not being able to determine the exact timing of injection valve or injector closing, and achieve the requirement of reducing calculation power and a large amount of precision , Optimize the effect of valve control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] It is pointed out that features or components of different embodiments that are identical or at least functionally identical to corresponding features or components according to this embodiment are provided with the same reference numerals. In order to avoid unnecessary repetition, features or components which have already been explained with reference to the previously described embodiments will not be explained in more detail below.

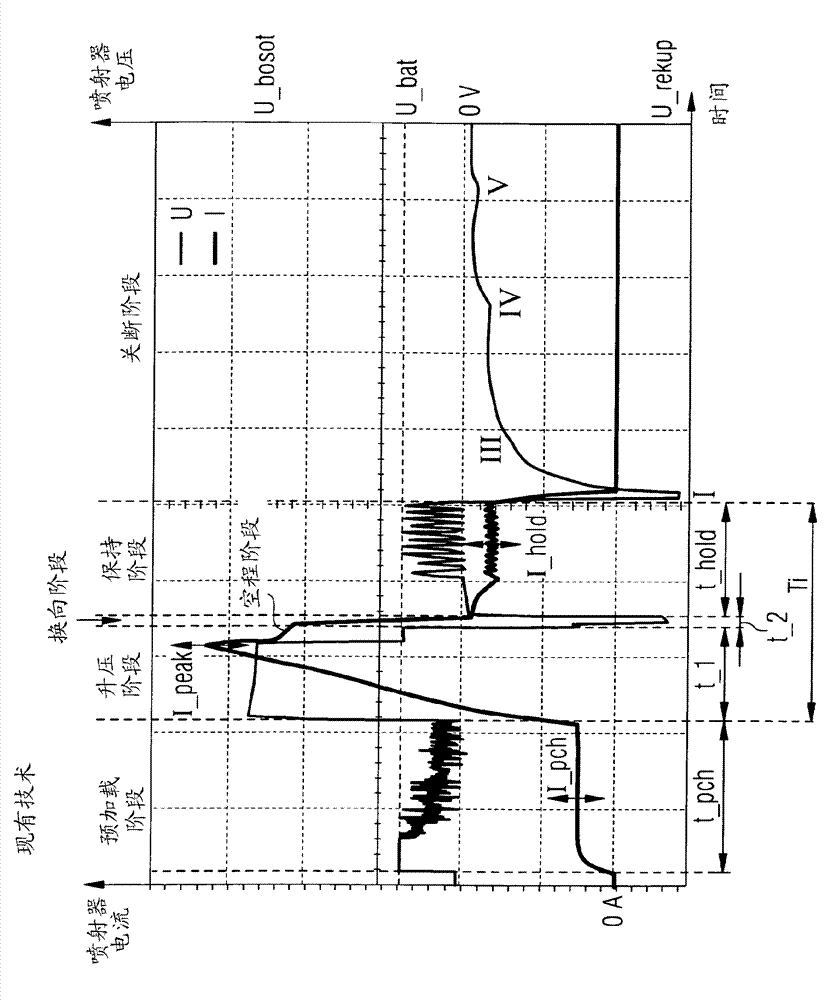

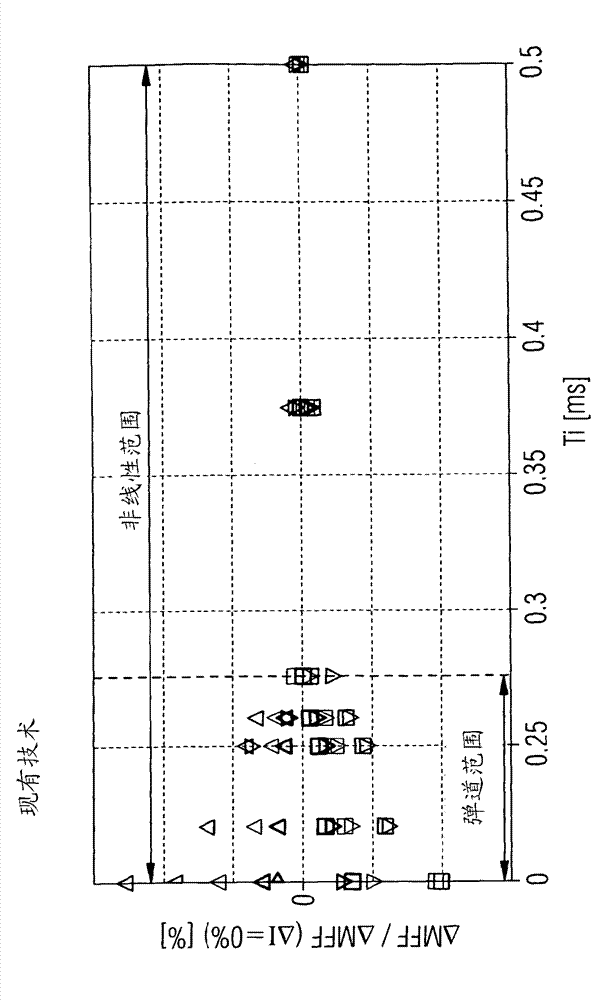

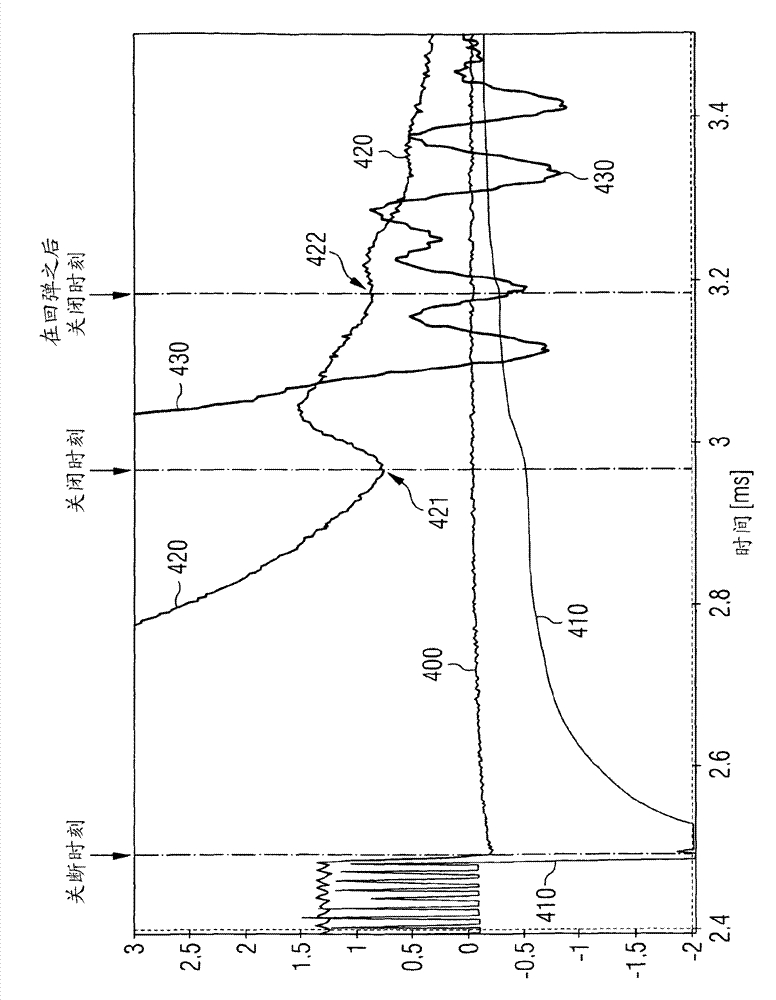

[0067] Figure 3a and Figure 1b The influence of the system tolerance on the injection accuracy as a function of the actuation duration Ti is consistently shown. The effect of a change in the current profile starting from the nominal control is shown in two steps each towards a higher and a lower current level. This change over five different current levels is carried out for the first injector with the smallest tolerance range and the second injector with the largest tolerance range. Altogether, 10 measurement points thus result for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com