Humidifier filter and humidifier filter laminate body

A filter and laminate technology, applied in the direction of air humidification system, application, heating method, etc., can solve problems such as breakage, bending and damage of filter substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] (filter substrate)

[0122] A polyethylene terephthalate film (hereinafter referred to as "PET film") having a thickness of 250 μm was used.

[0123] (coating of hydrophilic layer)

[0124] The following materials were mixed with a mixer to prepare a coating liquid for a hydrophilic layer.

[0125] Colloidal silica

[0126] (manufactured by Nissan Chemical Industry Co., Ltd., trade name: Snowtex (registered trademark) 20, 20% liquid) 70 parts

[0127] Styrene-butadiene copolymer resin

[0128] (manufactured by JSR Corporation, trade name: 3600H, 50% liquid) 30 parts

[0129] Silane coupling agent (3-aminopropyldimethoxymethylsilane) 1 part.

[0130] After transferring to the above-mentioned PET film with a gravure roll to which the coating liquid for a hydrophilic layer adhered, it was dried and coated with a hydrophilic layer having a thickness of 3 μm on both sides.

[0131] (Preparation of filter for humidification)

[0132] A circular (diameter: 141 mm) punchin...

Embodiment 2

[0136] (Preparation of filter for humidification)

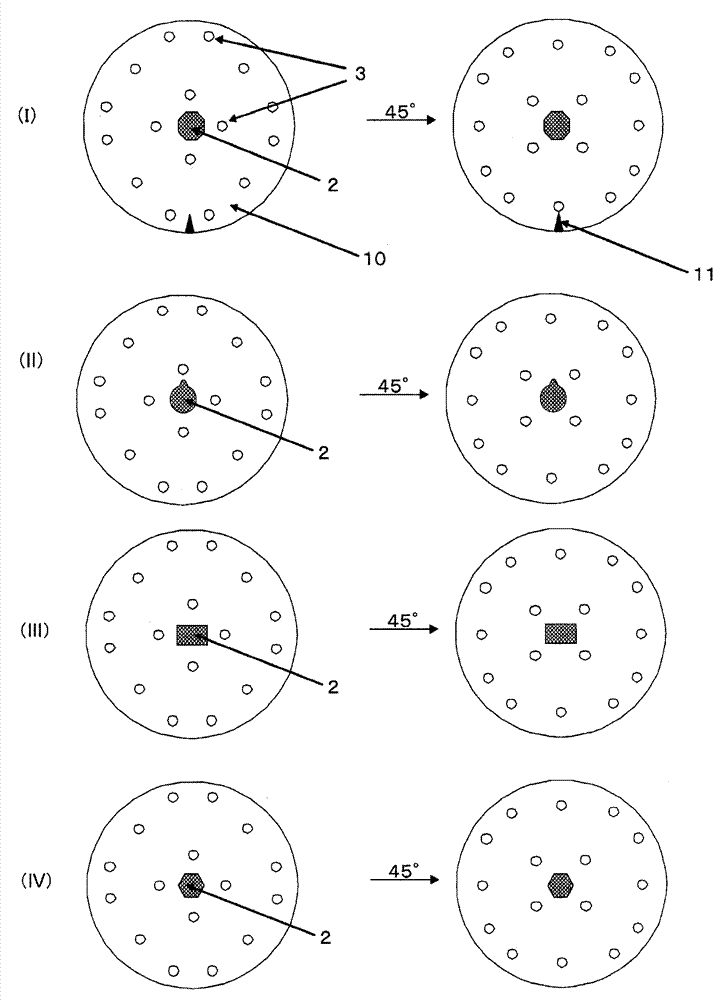

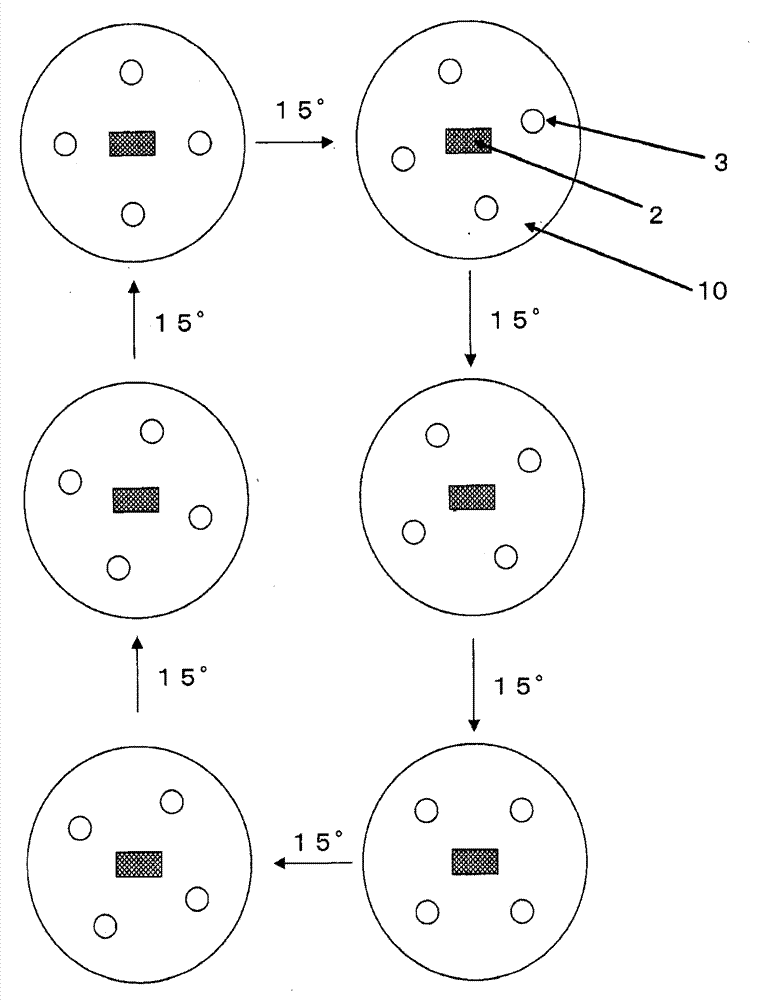

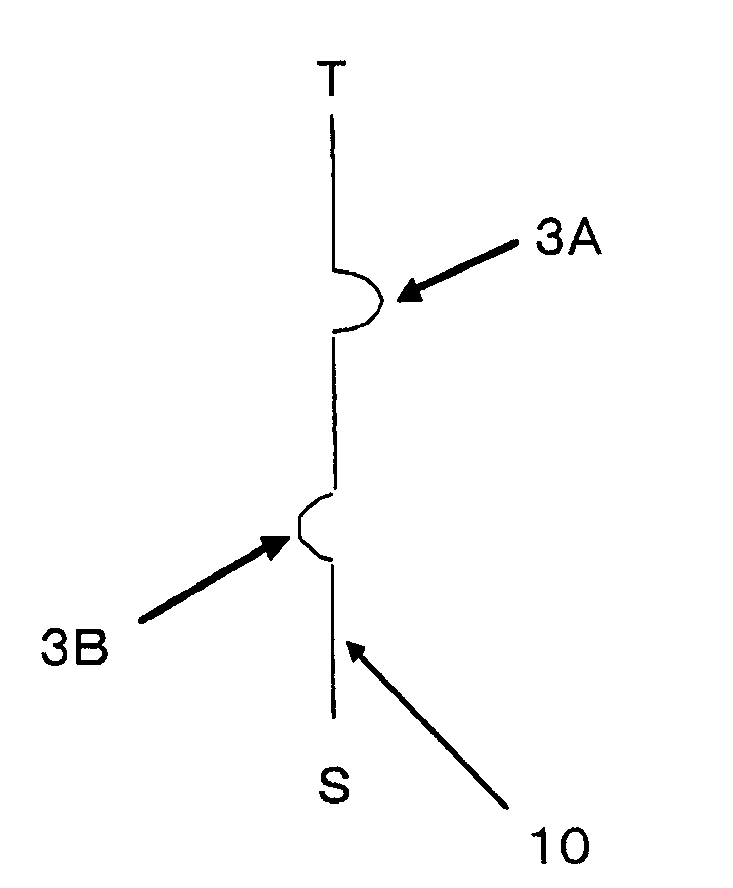

[0137] The PET film coated with the hydrophilic layer prepared in Example 1 is subjected to circular (141 mm in diameter) punching, and an opening (16.1 mm×10.1 mm) is formed in the center as a shaft through the punching process. hole 2. Such as Figure 8 As shown, 58 sheets of humidification filters 1E and 1F in which 16 protrusions (bowl-shaped) were formed on the filter substrate by extrusion were prepared. Protrusions 3A indicated by solid lines and protrusions 3B indicated by dotted lines are respectively formed on opposite surfaces of filter base material 10 . In addition, the protrusions of the humidification filters 1E and 1F are shifted by 45° in the circumferential direction. In the protrusions 3A and 3B, the diameter of the lowermost part was 5.0 mm, and the height was 1.5 mm. The obtained humidification filter had no defects such as bending.

[0138] (Preparation of filter laminate for humidification)

[013...

Embodiment 3

[0141] (Preparation of filter for humidification)

[0142] The PET film coated with the hydrophilic layer prepared in Example 1 is subjected to circular (141 mm in diameter) punching, and an opening (16.1 mm×10.1 mm) is formed in the center as a shaft through the punching process. hole 2. Such as Figure 4 As shown, 58 sheets of humidification filters 1C and 1D in which eight protrusions 3 (bowl-shaped) were formed only on one side of the filter substrate 10 were prepared by extrusion. The protrusions 3 of the humidification filter 1C and the protrusions 3 of the humidification filter D are respectively provided in circular shapes with different radii, and the mutual protrusions 3 may not overlap even when adjacent to each other. In addition, the diameter of the lowest part of the protrusion part 3 was 5.0 mm, and the height was 1.5 mm. The obtained humidification filter had no defects such as bending.

[0143] (Preparation of filter laminate for humidification)

[0144] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com