vacuum capacitor

一种电容器、真空的技术,应用在电容器、电容器制造、改变电极间距离的电容器等方向,能够解决低效热传递、增加冷却需求、消耗等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

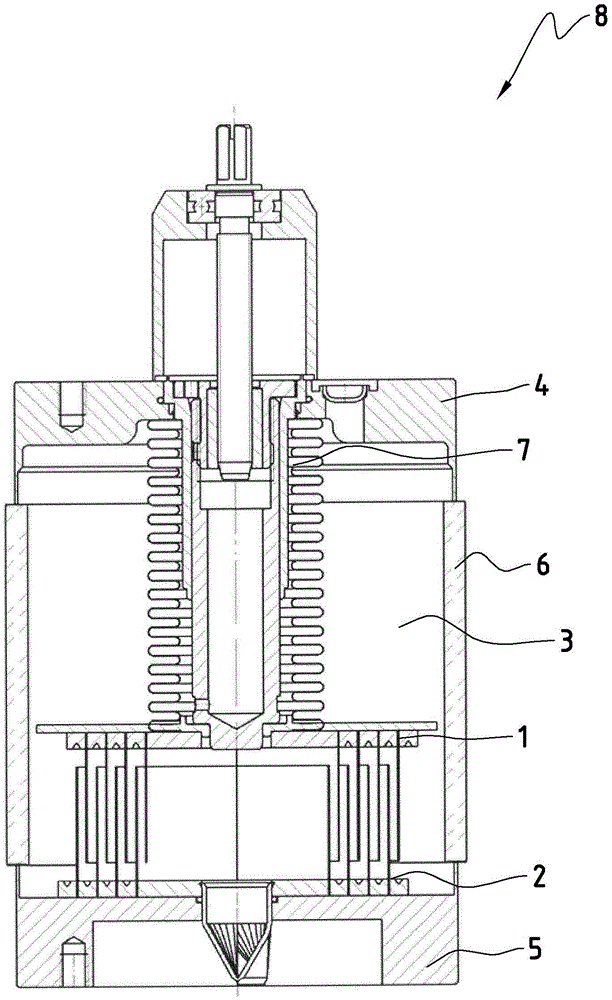

[0026] The present invention will refer to the attached figure 1 described, with figure 1 A typical variable vacuum capacitor arrangement is shown. The figure shows a device in which a set of stationary cylindrical electrodes (2) is spaced apart from a set of movable cylindrical electrodes (1) in a vacuum dielectric (3). The bellows (7) allow relative movement of the movable electrodes while maintaining the integrity of the vacuum dielectric (3) in the housing (4, 5, 6). The housing may comprise a ceramic housing wall (6) vacuum-tight bonded or otherwise secured to an end element, which may be made of an electrically conductive material. Here, it is pointed out that the end elements correspond to the conductive parts (4, 5) according to the invention.

[0027] As described above, selecting an electrode surface material of greater hardness and / or melting point may have the effect of limiting or slowing the development of avalanche breakdown if electrons or ions are ejected f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com