Flue-cured greenhouse seedling three-dimensional rotation automatic control device

An automatic control device and flue-cured tobacco technology are applied in the fields of agricultural gas emission reduction, botanical equipment and methods, soilless cultivation, etc., which can solve the problem of increasing the cost of seedlings, affecting the emergence speed of seedlings, and the quality of seedlings, and failing to make full use of seedlings. shed three-dimensional space and other problems, to achieve the effect of easy cleaning, improving space utilization, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings:

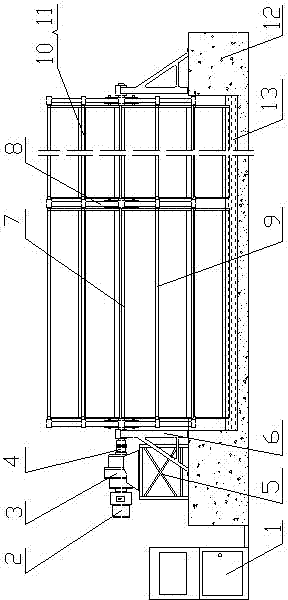

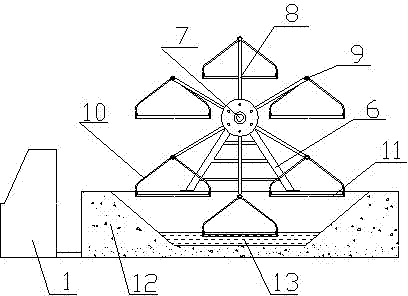

[0012] Set up a nursery pond (12) in the flue-cured tobacco nursery greenhouse, install an end bracket (6) at each end of the nursery pond (12), the nursery pond (12) is filled with seedling liquid (13), and two end brackets (6) ) The central rotating shaft (7) is connected in the middle, and eight groups of rotating arms (8) are hinged on the central rotating shaft (7) at intervals of 1.7m in the longitudinal direction. There are six rotating arms (8) in each group, and there are two rotating arms ( 8) The distance is 60°. The end of each pivot arm (8) is longitudinally connected to the tray shaft (9). The tray shaft (9) and the central shaft (7) are parallel to each other, and hinge on the tray shaft (9). Connect seven fence trays (9), place the seedling tray (11) in the fence tray (10), install the motor support (5) next to the left end support (6), the servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com