Bionic flytrap driven by shape memory alloy (SMA) wires

A technology of memory alloy wire and Venus flytrap is applied in the field of bionic Venus flytrap robots, which can solve the problems of high driving current, high battery requirements, inconvenient use, etc., and achieves the effects of light weight, good bionic effect and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

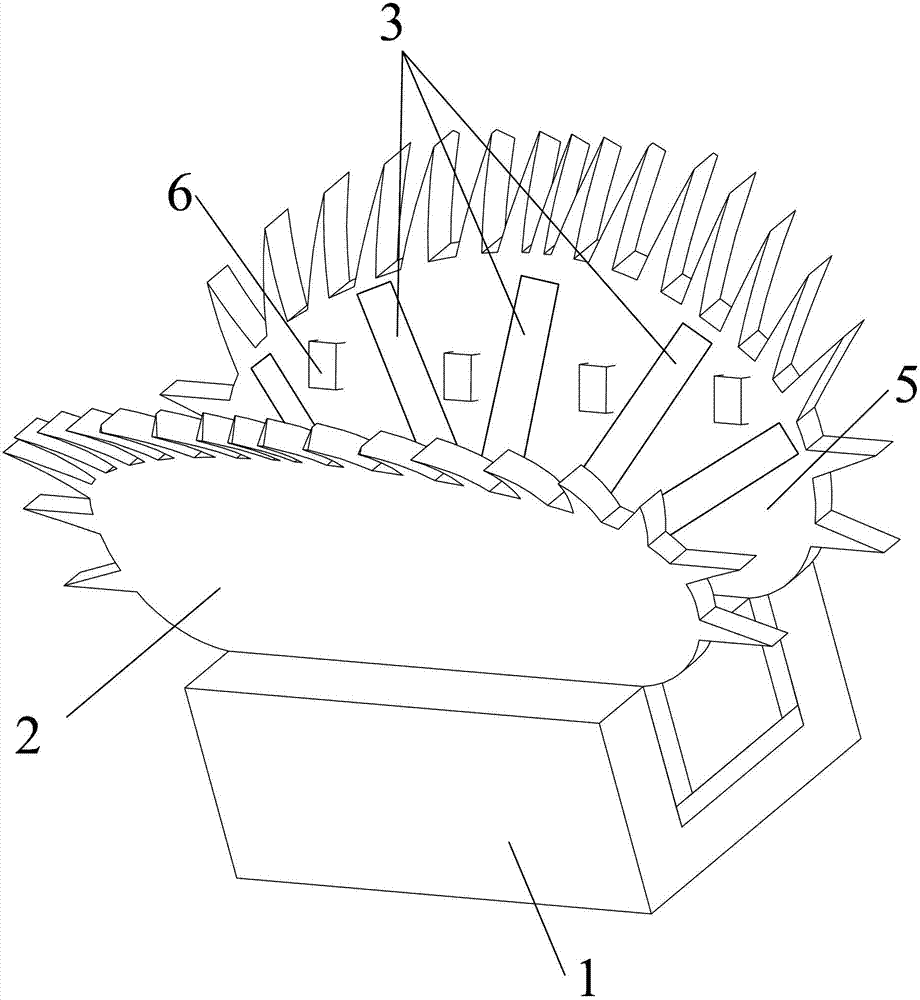

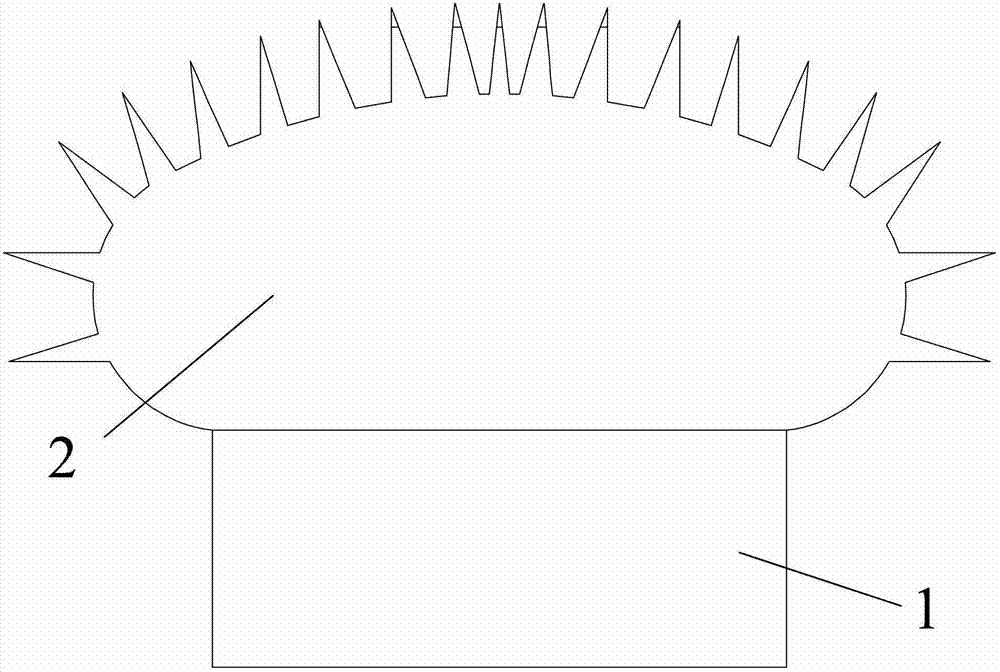

[0023] Specific implementation mode one: as Figure 1-7 As shown, a bionic flytrap driven by a shape memory alloy wire according to this embodiment includes a support 1, a left leaf 2 of the insect trap, a right leaf 5 of the insect trap, a fly sensing device 6 and two sets of shape memory alloy wires Driven reverse bending unit 3, the left blade 2 of the insect trap and the right blade 5 of the insect trap are all made of a material with certain elasticity and the shape of the two is consistent with the blade shape of the Flytraps, the left blade 2 of the insect trap, The right blade 5 of the insect trap is installed on the support 1, a group of reverse bending units 3 driven by shape memory alloy wires are respectively embedded in the left blade 2 of the insect trap, and the right blade 5 of the insect trap, and the fly sensing device 6 is arranged on the left side of the insect trap. Between the blade 2 and the right blade 5 of the insect trap, the reverse bending unit 3 dr...

specific Embodiment approach 2

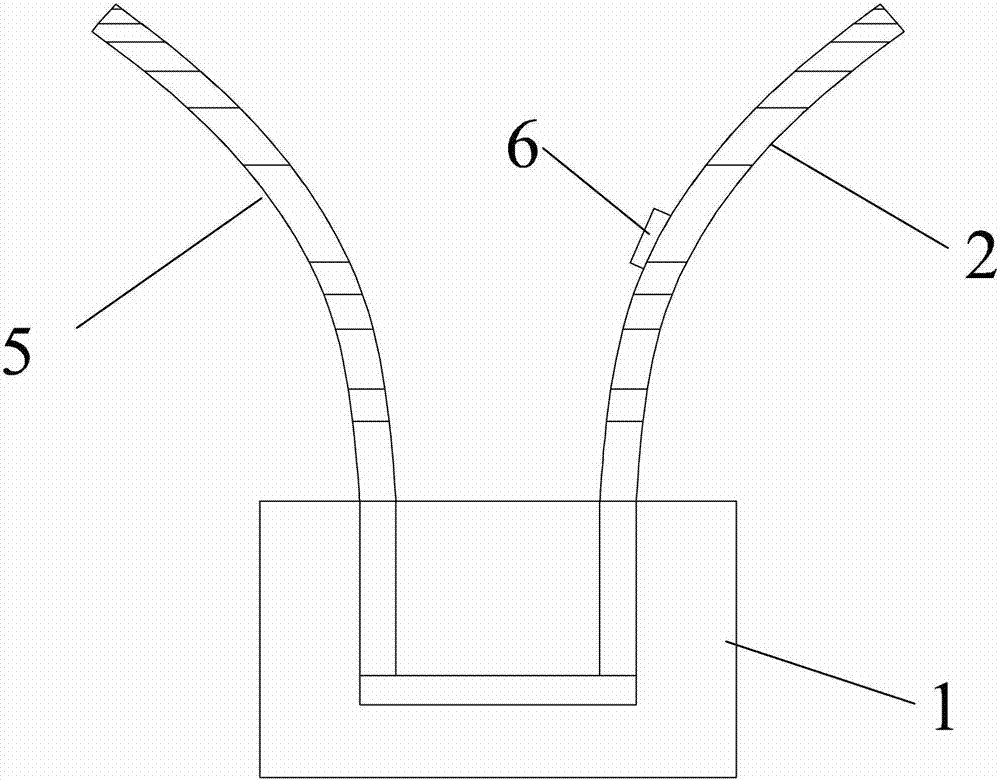

[0025] Specific implementation mode two: as Figure 1-9As shown, in this embodiment, each reverse bending unit 3 driven by a shape memory alloy wire has a flat curved elongated structure, and each reverse bending unit 3 driven by a shape memory alloy wire includes a shape memory alloy wire 7, a Mongolian The skin 8, the wire 9, the elastic body 10 and the support body 11, the wire 9 and the shape memory alloy wire 7 are connected, the shape memory alloy wire 7 is attached to the elastic body 10, the elastic body 10 is in a curved arc in the initial state, and the shape memory alloy wire 7 The wire 7 is located outside the arc of the elastic body 10, and the skin is wrapped on the shape memory alloy wire 7. The support body 11 is used to fix the elastic body 10 and the shape memory alloy wire 7, and each shape memory alloy wire is fixed by the support body 11. The wire driven reverse bending unit 3 is fixed to the base of the left blade 2 of the insect trap or the right blade 5...

specific Embodiment approach 3

[0026] Specific implementation mode three: as Figure 8-9 As shown, when the shape memory alloy wires 7 in the plurality of reverse bending units 3 in this embodiment are energized and contracted at the same time, the multiple reverse bending units simultaneously produce a bending action, thereby driving the left blade 2 of the insect trap and the right blade of the insect trap 5. Close up and shrink like a Venus flytrap. By controlling the shrinkage and deformation of the shape memory alloy wire 7 through electrical parameters, the bending range of the reverse bending unit can be controlled, so that the left blade 2 of the insect trap and the right blade 5 of the insect trap can form a closed space. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com