Processing method for roller sleeve of roller press

A processing method and technology of a roller press, applied in the field of roller press, can solve the problems affecting the wear resistance and service life of the wear-resistant layer, and achieve the effects of shortening downtime, good wear resistance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The process steps of the roller cover are as follows:

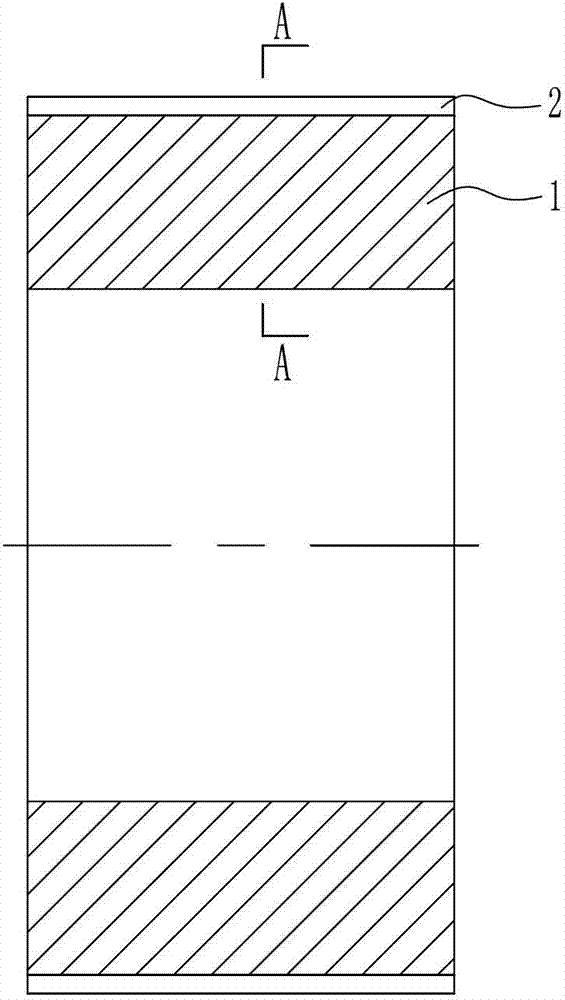

[0030] 1) Forging: the alloy steel ingot is processed into a blank sleeve body 1 by forging to form the basic shape of the roll sleeve, and the sleeve body 1 is a straight circular sleeve structure;

[0031] 2) The first heat treatment: the casing 1 is heated to 600°C at a rate of less than 50°C / h in the heat treatment furnace, and the temperature is maintained for 4 hours; And the heat preservation time is 8 hours; finally take it out of the oven and air cool;

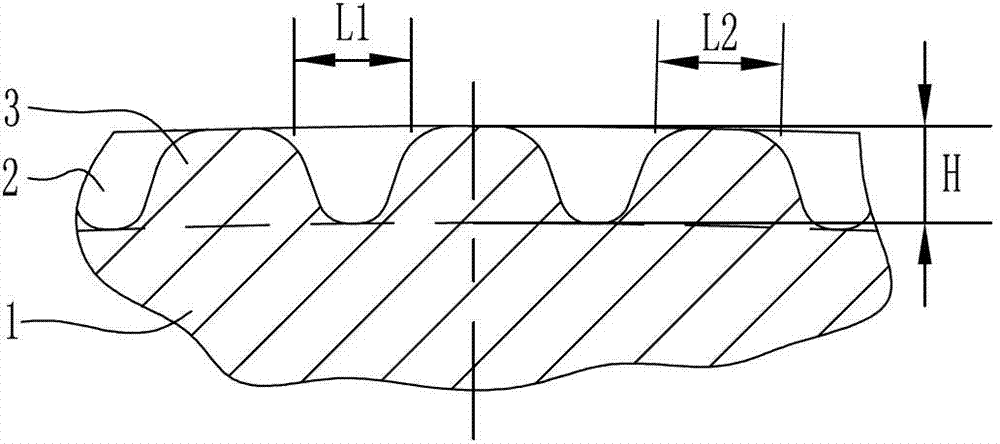

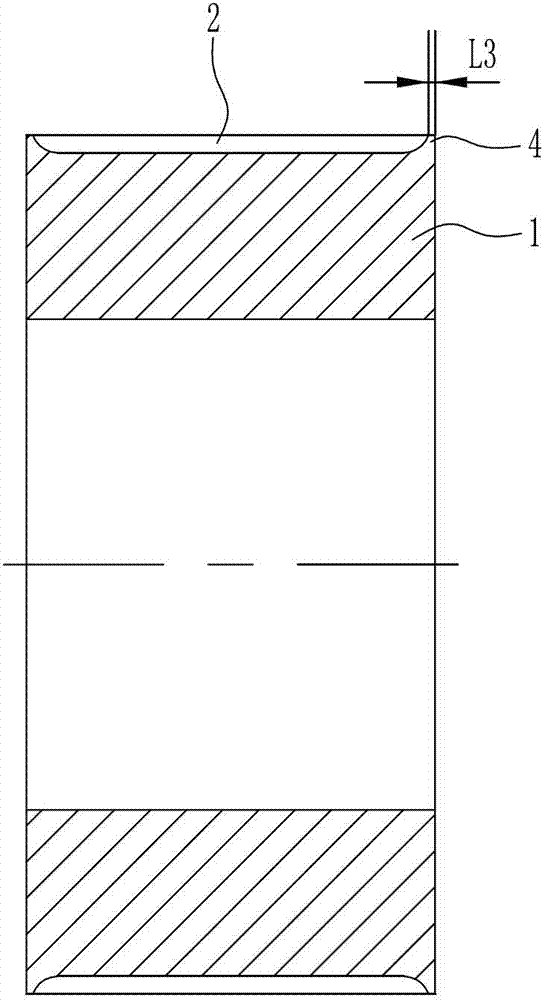

[0032] 3) The first machining: First, the shape of the sleeve body 1 is machined by turning, and then the grooves 2 are axially processed on the outer peripheral surface of the sleeve body 1 with a customized tool. The grooves 2 are evenly distributed on the circumference, and the two sides Inline ribs 3 are formed between adjacent grooves 2;

[0033] 4) The second heat treatment: heat the semi-finished product after the first machining to 600°C at a rat...

Embodiment 2

[0036] The process steps of the roller cover are as follows:

[0037] 1) Forging: the alloy steel ingot is processed into a blank sleeve body 1 by forging to form the basic shape of the roll sleeve, and the sleeve body 1 is a straight circular sleeve structure;

[0038] 2) The first heat treatment: the body 1 is heated to 650°C at a rate of less than 50°C / h in the heat treatment furnace, and the temperature is maintained for 5 hours; And the heat preservation time is 11 hours; finally take it out of the oven and air cool;

[0039] 3) The first machining: First, the shape of the sleeve body 1 is machined by turning, and then the grooves 2 are axially processed on the outer peripheral surface of the sleeve body 1 with a customized tool. The grooves 2 are evenly distributed on the circumference, and the two sides Inline ribs 3 are formed between adjacent grooves 2;

[0040]4) The second heat treatment: raise the temperature of the semi-finished product after the first machining...

Embodiment 3

[0043] The process steps of the roller cover are as follows:

[0044] 1) Forging: the alloy steel ingot is processed into a blank sleeve body 1 by forging to form the basic shape of the roll sleeve, and the sleeve body 1 is a straight circular sleeve structure;

[0045] 2) The first heat treatment: the casing 1 is heated to 700°C at a rate of less than 50°C / h in the heat treatment furnace, and the temperature is maintained for 6 hours; And the time of heat preservation is 14 hours; finally it is out of the oven and air-cooled;

[0046] 3) The first machining: First, the shape of the sleeve body 1 is machined by turning, and then the grooves 2 are axially processed on the outer peripheral surface of the sleeve body 1 with a customized tool. The grooves 2 are evenly distributed on the circumference, and the two sides Inline ribs 3 are formed between adjacent grooves 2;

[0047] 4) The second heat treatment: raise the temperature of the semi-finished product after the first mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com