Special fertilizer used for sterilizing and weeding

A special fertilizer, weight percentage technology, applied in fertilizer mixtures, applications, fertilization devices, etc., can solve problems such as loss, weakened crop protection against pests and diseases, and achieve the effect of inhibiting absorption and meeting demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

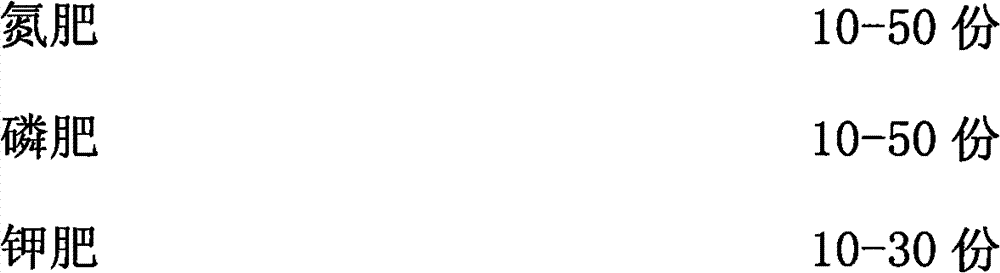

[0016] The present invention is made up of following weight percent components:

[0017]

[0018] The preparation method is to mix the above-mentioned raw material components, stir them evenly with a mixer, grind them into 80-120 mesh powders with a pulverizer, granulate them in a granulator, dry the granular materials, and the maximum temperature of the heat source of the dryer The temperature is 200°C, the outlet is 70°C, the water content of the material is less than 5% after drying, and finally sieved, the fertilizer with a particle size of 2-3mm is weighed, and the fertilizer is packaged.

Embodiment 2

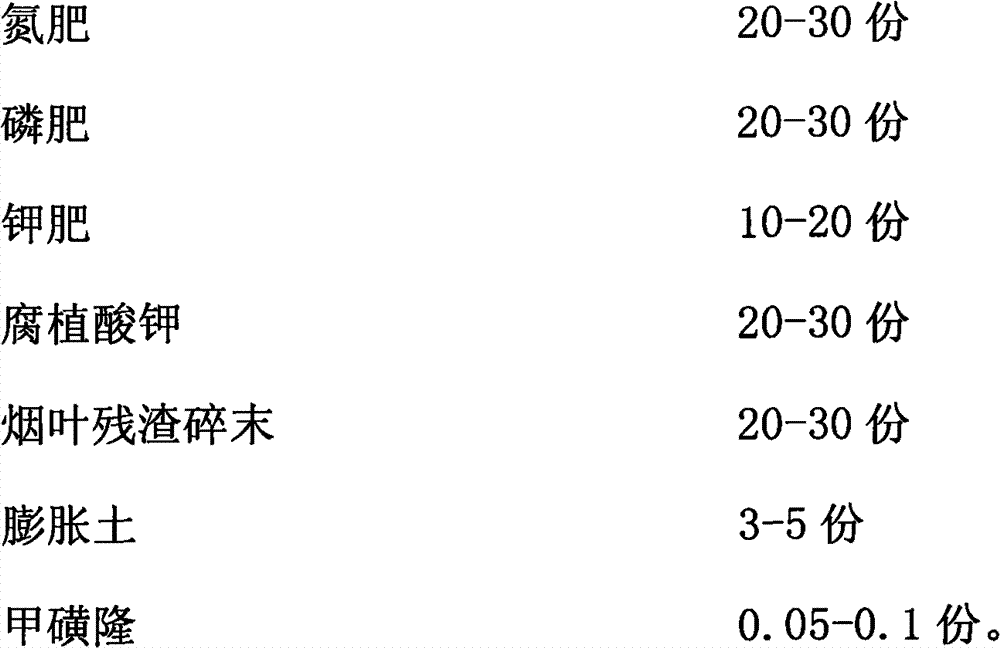

[0020] Consists of the following components by weight percentage:

[0021]

[0022]

[0023] The preparation method is to mix the above-mentioned raw material components, stir them evenly with a mixer, grind them into 80-120 mesh powders with a pulverizer, granulate them in a granulator, dry the granular materials, and the maximum temperature of the heat source of the dryer The temperature is 250°C, the outlet is 50°C, the water content of the material is less than 5% after drying, and finally sieved, the fertilizer with a particle size of 1-2mm is weighed, and the fertilizer is packaged.

Embodiment 3

[0025] Consists of the following components by weight percentage:

[0026]

[0027] The preparation method is to mix the above-mentioned raw material components, stir them evenly with a mixer, grind them into 80-120 mesh powders with a pulverizer, granulate them in a granulator, dry the granular materials, and the maximum temperature of the heat source of the dryer The temperature is 220°C, the outlet is 60°C, the water content of the material is less than 5% after drying, and finally sieved, the fertilizer with a particle size of 2-3mm is weighed, and the fertilizer is packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com