Ultrahigh-toughness flame-retardant polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of polypropylene composite materials and its preparation, can solve the problems of material mechanical properties, material rigidity reduction, impact performance reduction, etc., to achieve continuity, high flame retardancy, and maintenance The effect of completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

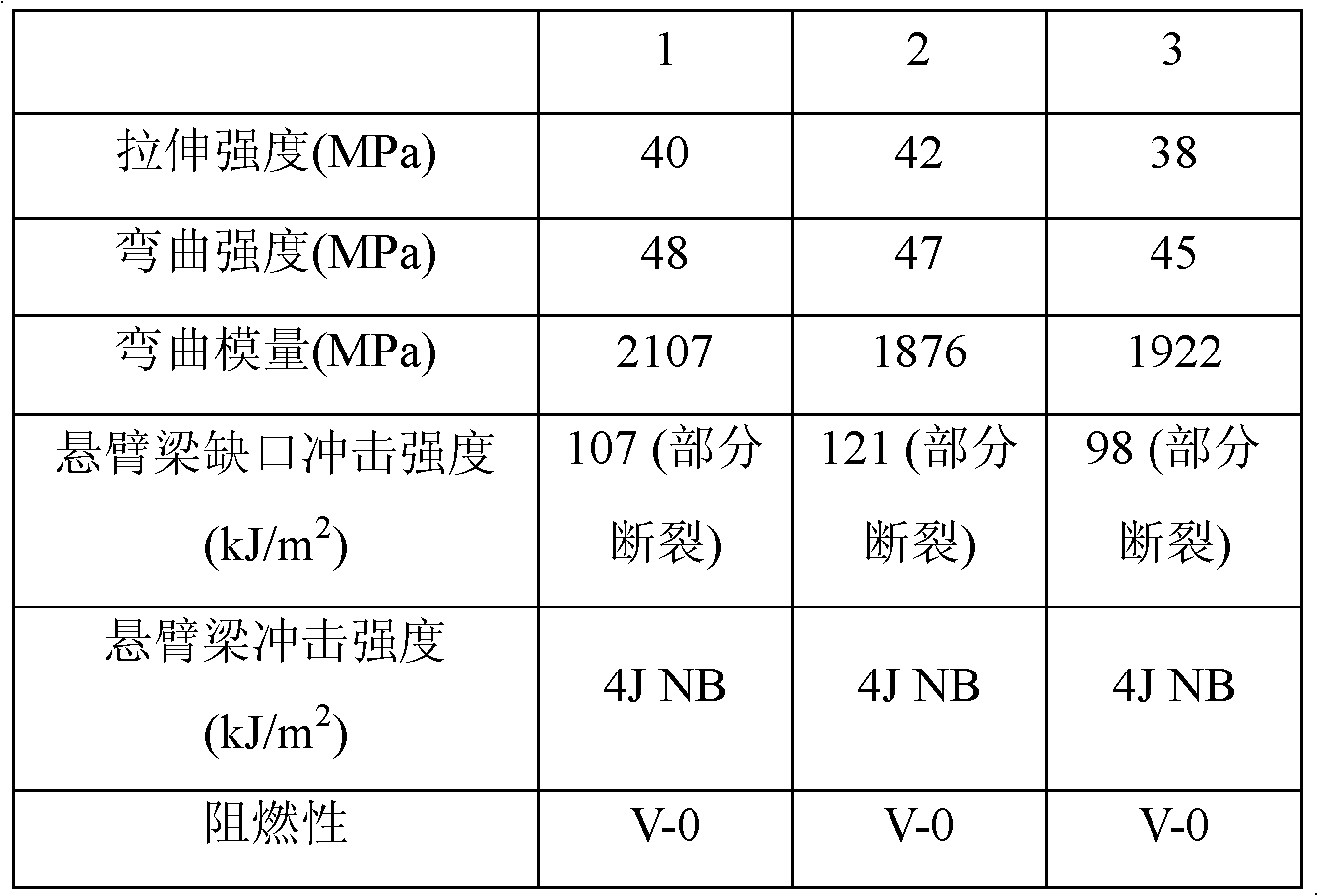

Embodiment 1

[0054] (1) Preparation of PET fiber reinforced toughened polypropylene composite material:

[0055] Polypropylene 66.1%, maleic anhydride grafted polypropylene 3%, antioxidant 10100.2%, antioxidant 1680.4%, lubricant amide wax 0.3% are plasticized and melted at a temperature of 180-200 ℃ to obtain a polypropylene resin Melt; continuous PET (polyethylene terephthalate) fibers are impregnated through the melt of the polypropylene resin such that the PET fibers are completely wetted out. Wherein, the continuous PET fiber is drawn from the creel, the tension is adjusted by the tension roller, and enters the melt impregnation die, and the dispersion and infiltration of the fiber are realized in the die, and the fiber content is controlled to be 30% by the outlet of the fiber of the die. %, cooled and solidified, and cut into 10mm length by pelletizer to obtain PET fiber reinforced toughened polypropylene composite material.

[0056] (2) Preparation of decabromodiphenylethane flame...

Embodiment 2

[0061] (1) Preparation of PET fiber reinforced toughened polypropylene composite material:

[0062] Plasticize and melt 66.4% polypropylene, 3% copolymer of glycidyl methacrylate and polypropylene, 10100.2% antioxidant, and 1680.4% antioxidant at a temperature of 180-200°C to obtain a polypropylene resin melt ; The continuous PET (polyethylene terephthalate) fiber is impregnated through the melt of the polypropylene resin, so that the PET fiber is completely soaked. Wherein, the continuous PET fiber is drawn from the creel, the tension is adjusted by the tension roller, and enters the melt impregnation die, and the dispersion and infiltration of the fiber are realized in the die, and the fiber content is controlled to be 30% by the outlet of the fiber of the die. %, cooled and solidified, and cut into 10mm length by pelletizer to obtain PET fiber reinforced toughened polypropylene composite material.

[0063] (2) Preparation of ammonium polyphosphate flame retardant masterbat...

Embodiment 3

[0068] (1) Preparation of nylon 66 fiber reinforced toughened polypropylene composite material:

[0069] Polypropylene 55.4%, maleic anhydride grafted polypropylene 4%, antioxidant 10980.2%, antioxidant 1680.4% are plasticized and melted at a temperature of 180-200°C to obtain a polypropylene resin melt; continuous nylon 66 The fibers are impregnated with the melt of the polypropylene resin so that the nylon 66 fibers are completely wetted. Wherein, described continuous nylon 66 fiber is drawn by creel, adjusts tension through tension roller, enters melt impregnation die head, realizes the dispersion and infiltration of fiber in die head, the content of controlling fiber by the outlet of the fiber of die head is 40%, cooled and solidified, and cut into 12mm length by pelletizer to obtain nylon 66 fiber reinforced toughened polypropylene composite material.

[0070] (2) Preparation of decabromodiphenylethane flame retardant masterbatch:

[0071] Add 59.7% polypropylene, 30% d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com