Ti80 titanium alloy standard substance and preparation method thereof

A standard material, titanium alloy technology, applied in the field of analysis and detection, can solve the problems of lack of Ti80 titanium alloy series standard material, difficult to guarantee uniformity, difficult to achieve uniformity, etc., and achieve a reliable and easy preparation method, accurate control and guarantee. The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of Ti80 titanium alloy standard substance of the present invention specifically implements according to the following steps:

[0042] (1) Ingredients: The ingredients are calculated according to the content requirements of each element of the Ti80 titanium alloy standard substance, and the grade 0 sponge titanium, AlMo50 master alloy, AlNb50 master alloy, AlSi24 master alloy, sponge zirconium, pure iron, Pure aluminum and graphite are used as raw materials. The use of grade 0 sponge titanium can avoid the influence of impurities in the sponge titanium, and the selection of sponge titanium with a diameter of 3~5mm can make the distribution of the sponge titanium more uniform. Since the melting point of sponge titanium is 1668±4°C, the density is 4.51g / cm 3 ;The melting point of metal aluminum is 600°C, and the density is 2.70g / cm 3 ; The melting point of metal molybdenum is 2610°C, and the density is 10.2g / cm 3 ; The melting point of metal niobi...

Embodiment

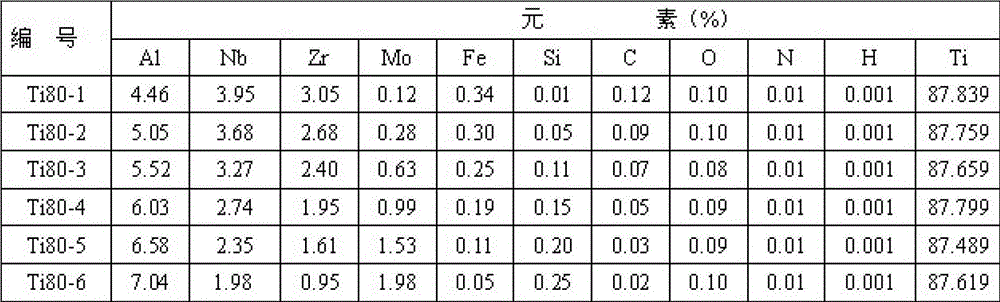

[0053] Example, Ti80 titanium alloy standard substance and preparation method thereof, Ti80 titanium alloy standard substance Ti80-1, Ti80-2, Ti80-3, Ti80-4, Ti80-5 and Ti80-6 were prepared. Its weight components are shown in Table 1,

[0054] The specific ingredients are shown in Table 2.

[0055] 1. Preparation of Ti80-1

[0056] Concrete preparation steps are as follows:

[0057] (1) Ingredients: Calculated on the basis of 100kg of feeding material, 87.5kg of titanium sponge, 0.19kg of AlMo50 master alloy, 8.08kg of AlNb50 master alloy, 3.03kg of sponge zirconium, 0.36kg of pure iron, 0.71kg of pure aluminum and 0.13kg of graphite are taken as raw materials. The use of grade 0 sponge titanium can avoid the influence of impurities in the sponge titanium, and the selection of sponge titanium with a diameter of 3~5mm can make the distribution of the sponge titanium more uniform. Since the melting point of sponge titanium is 1668±4°C, the density is 4.51g / cm 3 ;The melting ...

Embodiment T

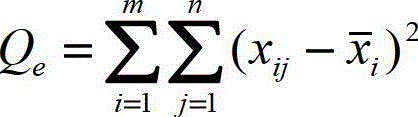

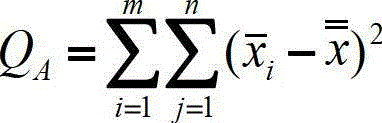

[0085] Table 3 embodiment Ti80 titanium alloy standard substance homogeneity

[0086]

[0087] Fixed value analysis: Use the Grubbs test criterion to test the original fixed value data to eliminate suspicious values, and then examine the normality of the data distribution. The test results are all in line with normal or quasi-normal distribution. Check whether the accuracy of each group of data is equal, after checking there is no abnormal data group, and then determine the standard value and uncertainty according to GB / T15000.3-2008.

[0088] Working curve inspection: In order to test the applicability of this set of standard materials, a set of standard materials was randomly selected, and the best conditions were selected for excitation with the ARL4460 photoelectric spectrometer to collect its light intensity, and the working curve was drawn with the standard value and light intensity. The meshing coefficients of the working curves are all above 0.99 (see Table 4 for de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com