Nanofiber low-voltage electro-spinning device with auxiliary electrodes

An auxiliary electrode, nanofiber technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of large difference in fiber diameter, discontinuous production process, high injection voltage threshold, and achieve complete solvent evaporation, Improve quality and achieve the effect of directional deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

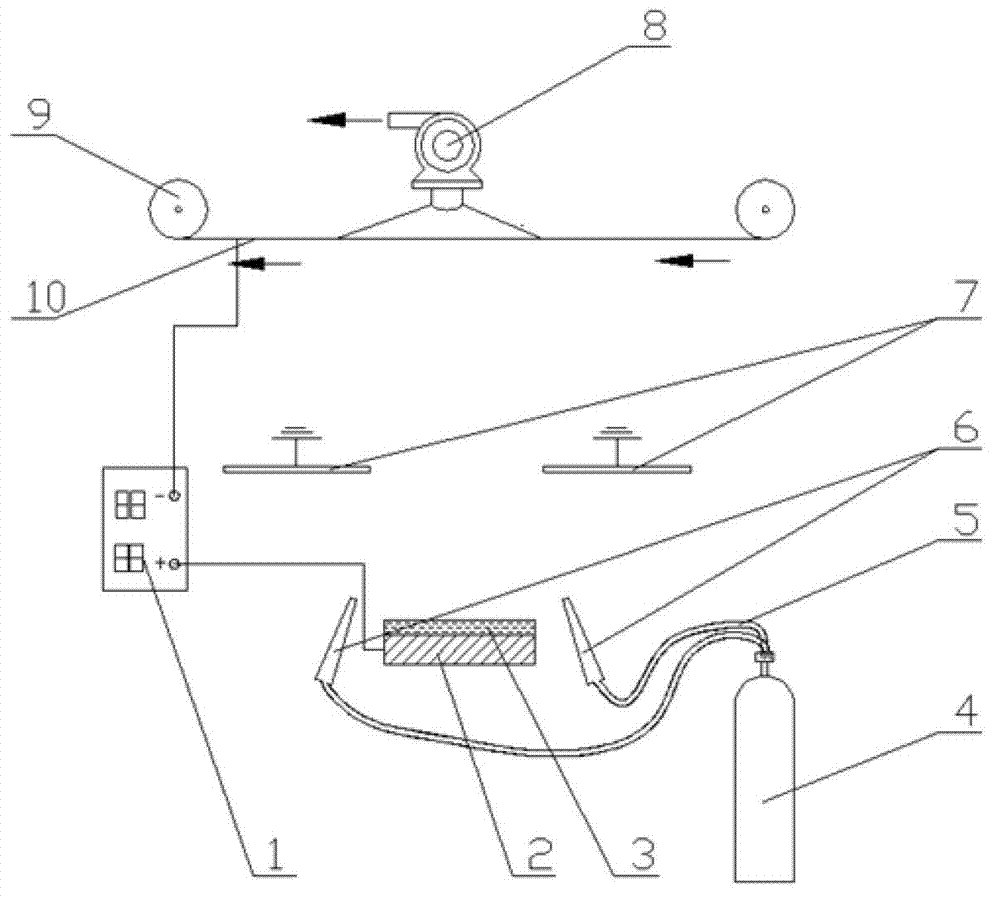

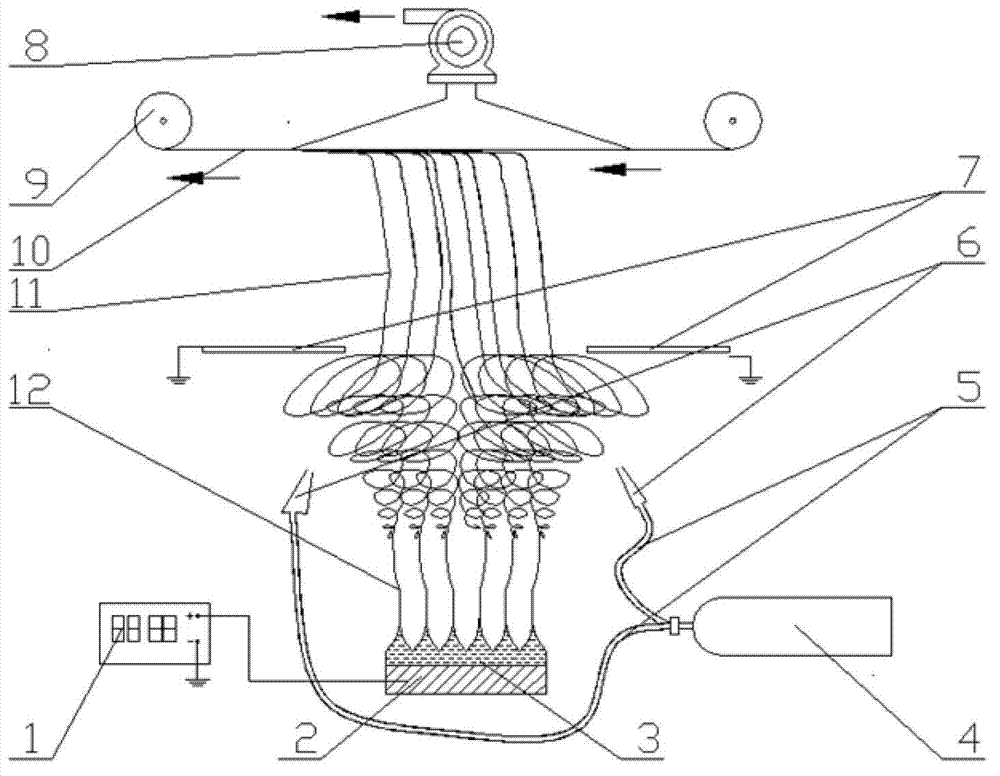

[0011] see figure 1 with 2 , The embodiment of the present invention is provided with a DC high-voltage power supply 1, a conductive electrode plate 2, a high-pressure gas source 4, an air duct 5, an array nozzle 6, an auxiliary electrode 7, a fan 8, a roller 9 and a collecting plate 10. DC high-voltage power supply 1 is used to generate high voltage, the positive electrode is connected to the conductive electrode plate 2, and the negative electrode is grounded; the polymer solution 3 is arranged on the conductive electrode plate 2, and jet jet 12 is generated on the upper surface of the solution during electrospinning; The gas pipe 5 is connected to the array nozzle 6 to provide high-pressure gas for the array nozzle 6; the array nozzle 6 is arranged between the auxiliary electrode 7 and the conductive electrode plate 2, and the gas ejected is used to change the flight direction of the fiber 11, and the nanofiber 11 follows the air flow from the auxiliary The gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com