Drill rod detaching device for hydraulic rig

A technology of dismantling device and hydraulic drilling rig, applied in drill pipe, drill pipe, drilling equipment, etc., can solve problems such as deformation of drill pipe, excessive handle, and injury caused by misfit, so as to avoid personal injury accidents, reduce labor intensity, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

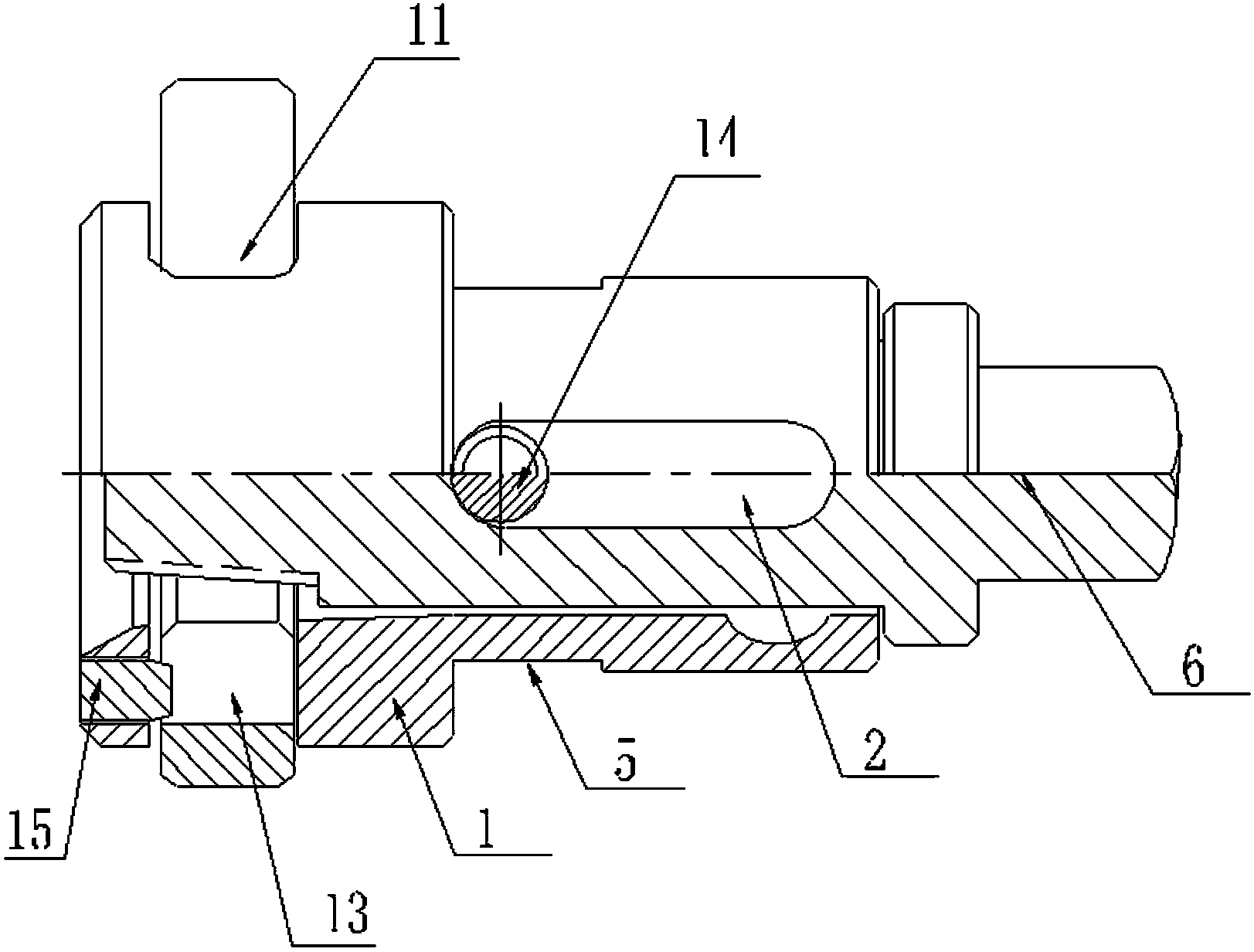

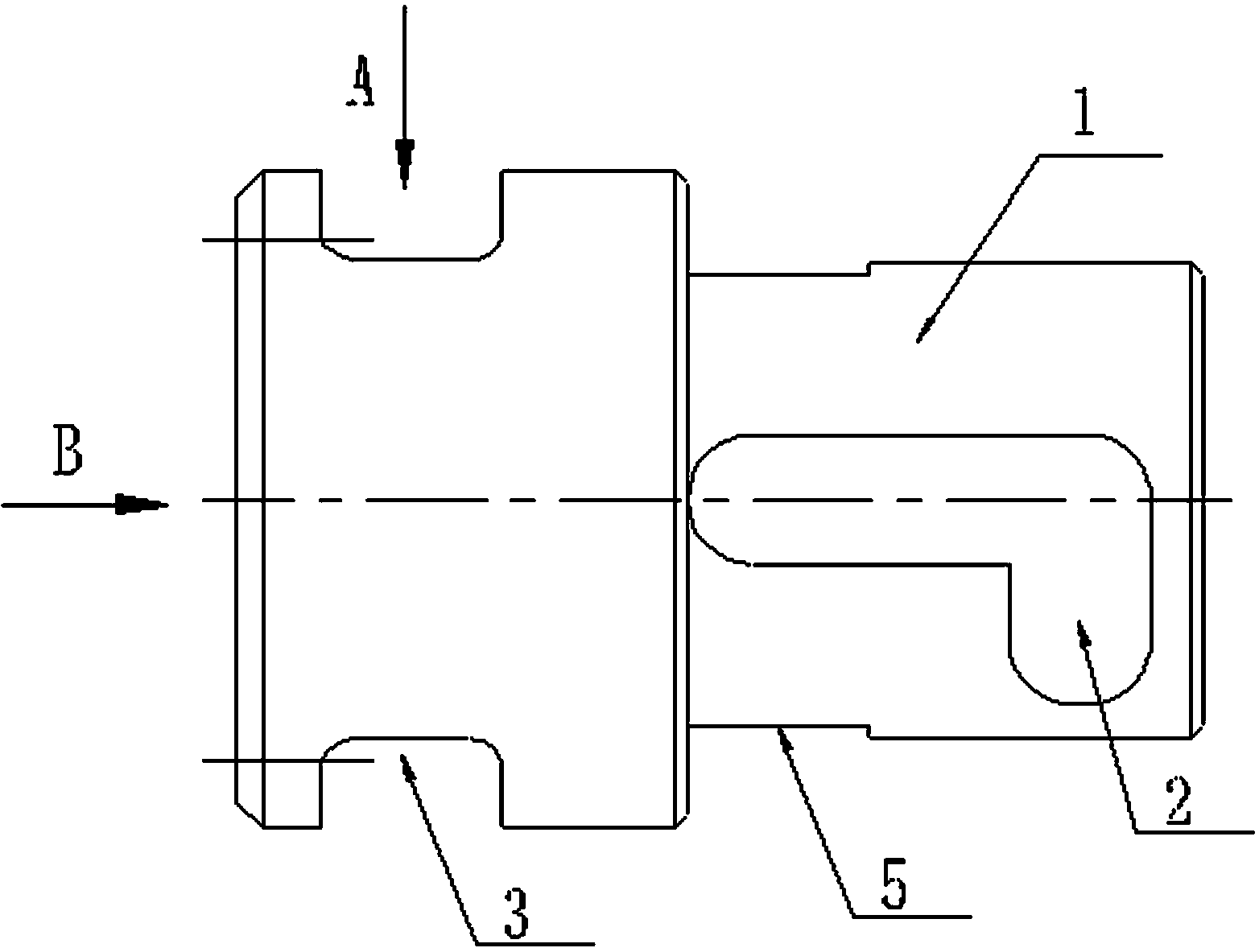

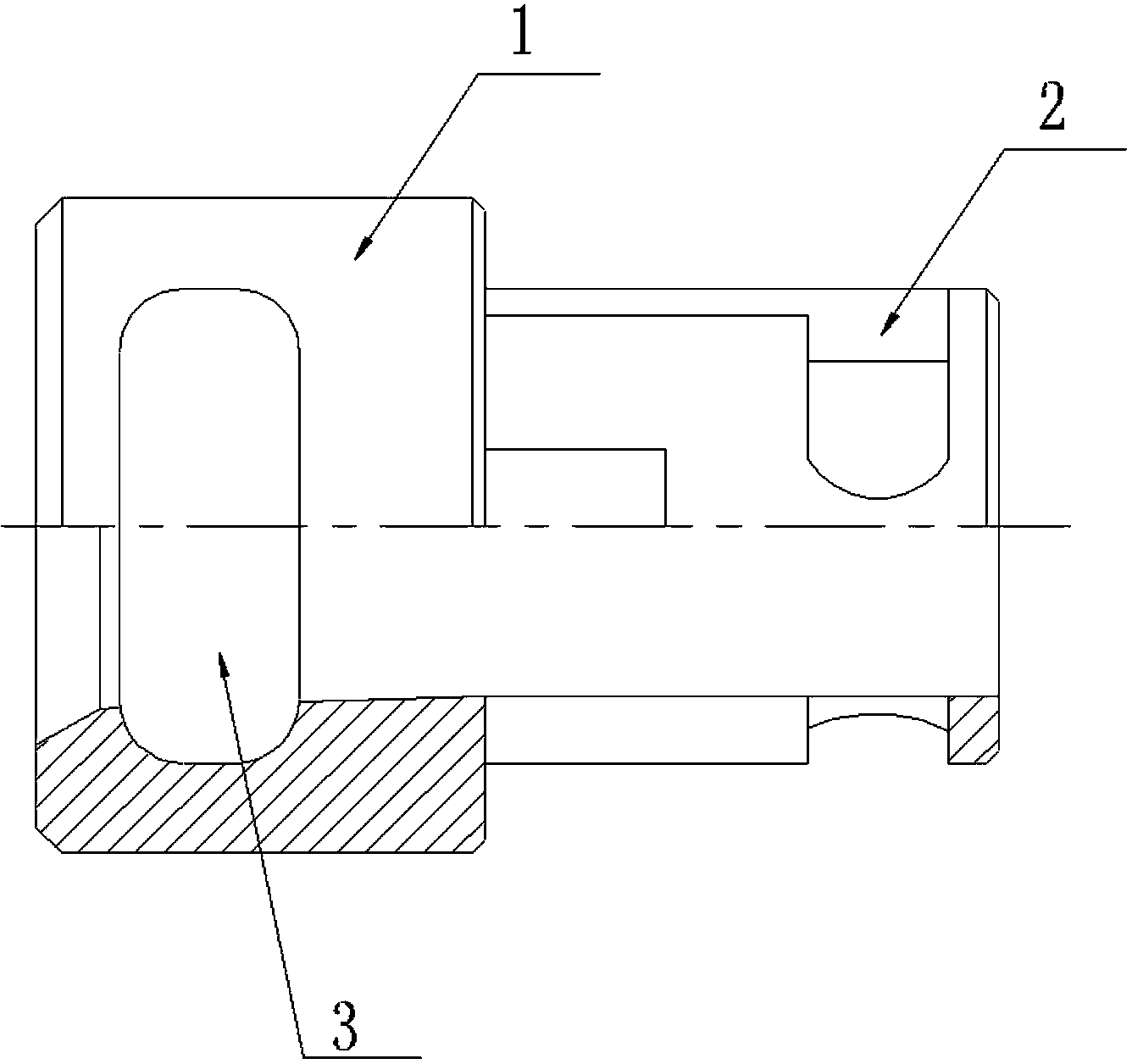

[0024] Reference Figure 1 to Figure 9 The drill rod disassembly device of the hydraulic drilling machine includes a sleeve 1, a cylindrical guide rod 6 and a clamp 11 for clamping the drill rod. One end of the sleeve 1 is provided with a clamp socket 3 radially penetrating the sleeve, and on the sleeve wall An L-shaped positioning guide groove 2 is provided. Preferably, the sleeve 1 is provided with two L-shaped positioning guide grooves 2, and the two L-shaped positioning guide grooves 2 are located on the same diameter of the sleeve 1. The sleeve 1 is symmetrically provided with a cutting plane 5 on the circumferential surface, which is convenient for holding the sleeve 1 for axial movement or circumferential rotation. The sleeve 1 is provided with two symmetrical axial end faces at the end where the clip socket 3 is provided. The positioning holes 4 for limiting the position of the clip 11 are respectively arranged beside the sleeve barrel holes. The clip 11 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com