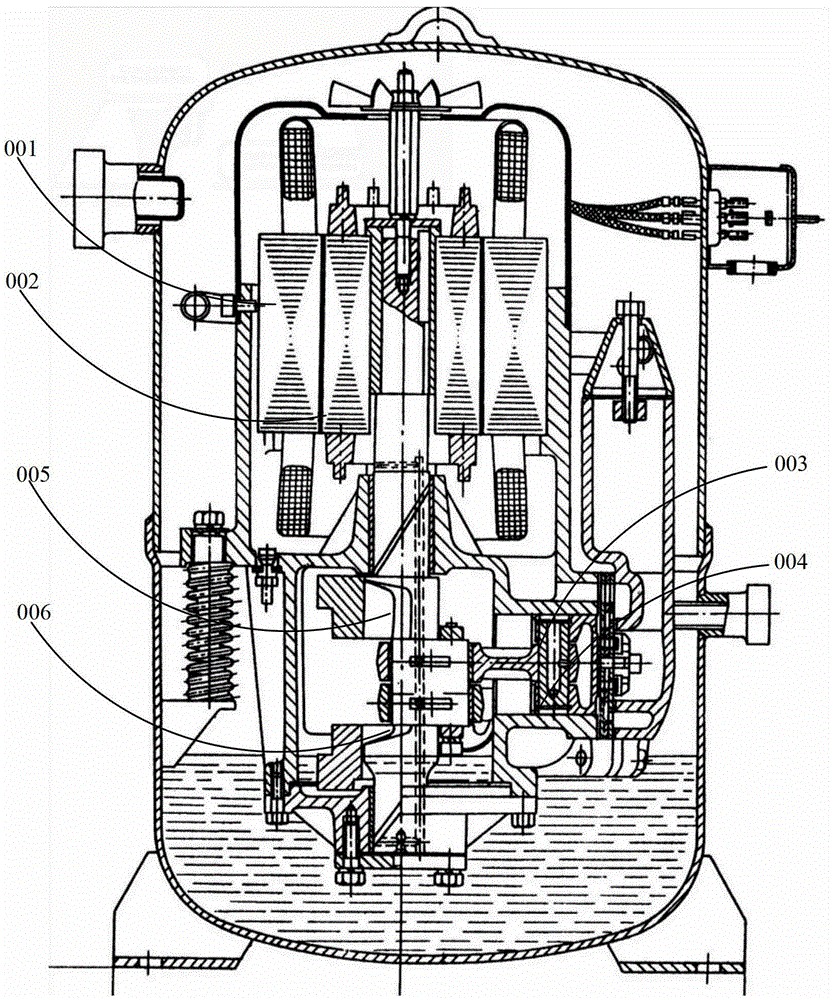

a ring compressor

A compressor and annular technology, which is applied in the field of annular compressors, can solve the problems of not considering the effect of gas force on the stationary slider, not giving an operable driving method, and the difficulty of keeping the stationary slider stationary, etc., so as to improve the electromechanical conversion Efficiency, simple structure, and improved electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing and example.

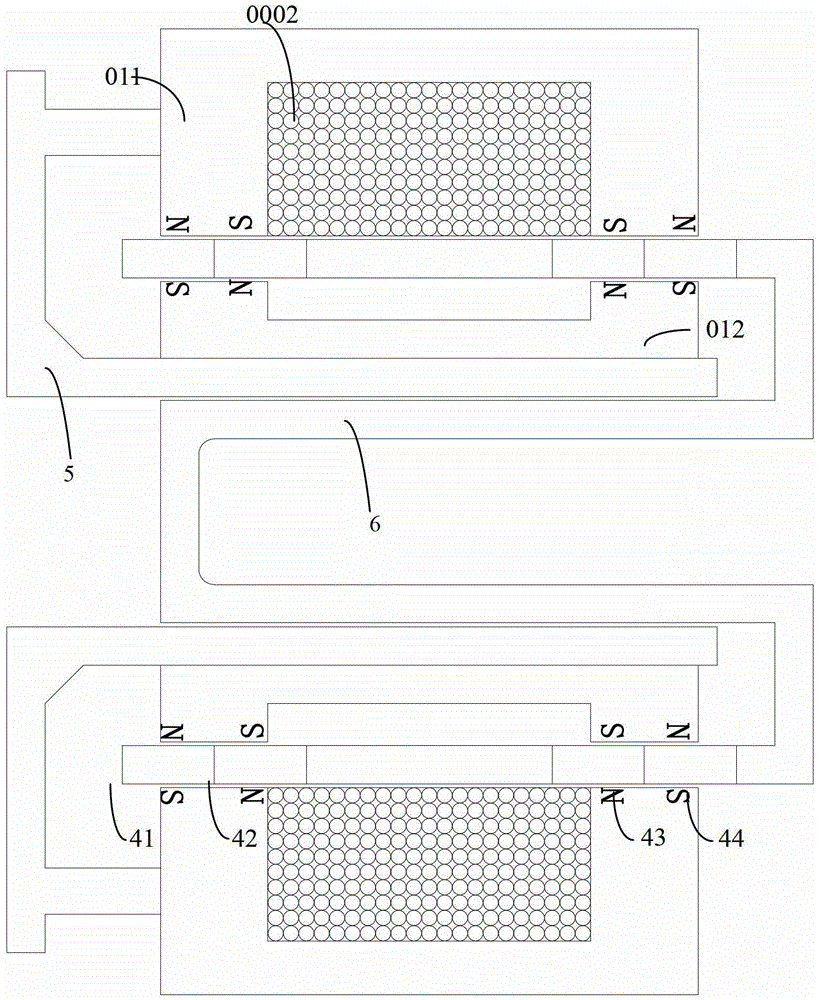

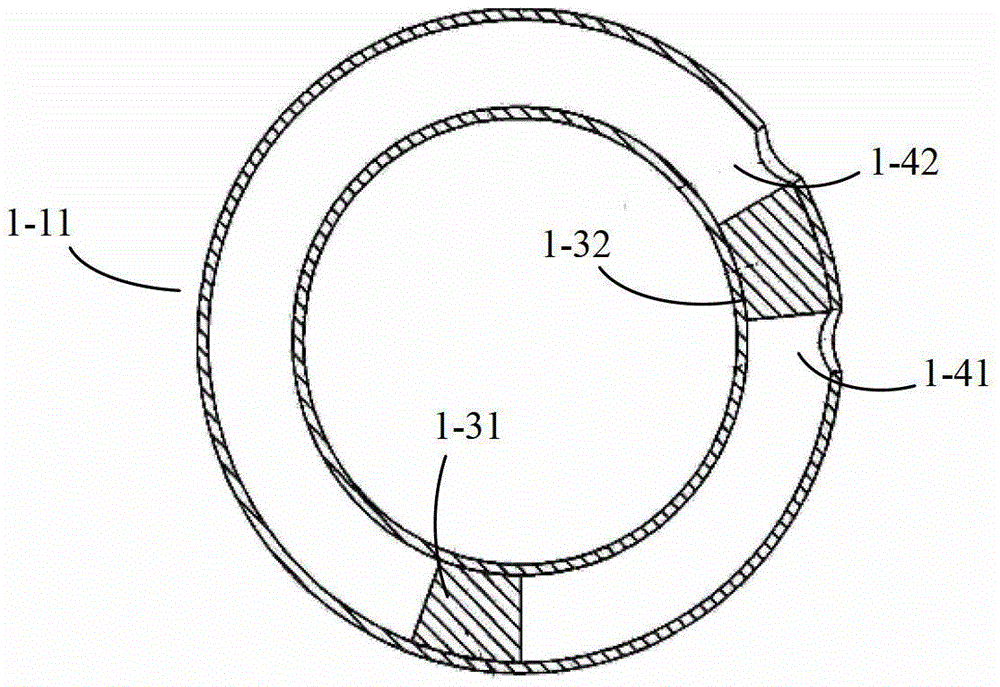

[0033] image 3 An embodiment of the annular compressor of the present invention is given, including an annular cavity 1, an annular stator yoke 2 with a tooth groove structure, the annular cavity 1 is located inside the annular stator yoke 2, the two are concentric, and there is no or only a small Clearance (within 3mm). The inner surface of the yoke 2 has a cogged structure, and a coil is wound on the cogged structure, and the coil is connected to an external power source. The slider 4 is located inside the annular cavity, the slider 4 is in close contact with the inside of the annular cavity, and can slide along the entire circumference of the inner wall of the annular cavity. The slider 4 is equipped with permanent magnets, so that at least one single magnetic pole or at least one pair of alternating magnetic poles are formed on its outer circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com