Thermal insulating layer for hot channel of hypersonic-velocity wind tunnel

A hypersonic, heat pipe technology, applied in the testing, measuring devices, instruments, etc. of machine/structural components, can solve the problems of contamination flow field of thermal insulation materials, loss of thermal insulation materials, damage to test equipment, etc., and achieve good economic benefits , prolong the service life and eliminate the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

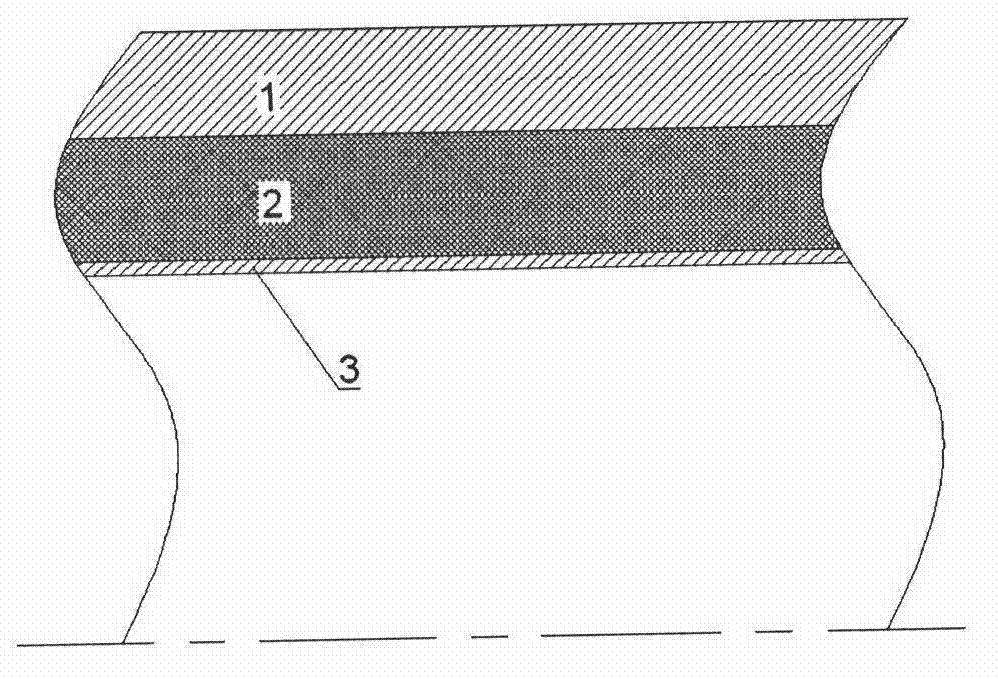

[0026] A heat insulation layer for a heat pipe of a hypersonic wind tunnel. The heat pipe of a hypersonic wind tunnel is composed of a pressure-bearing shell, a heat insulation layer and an inner lining from outside to inside; no pressure balance holes are provided on the lining;

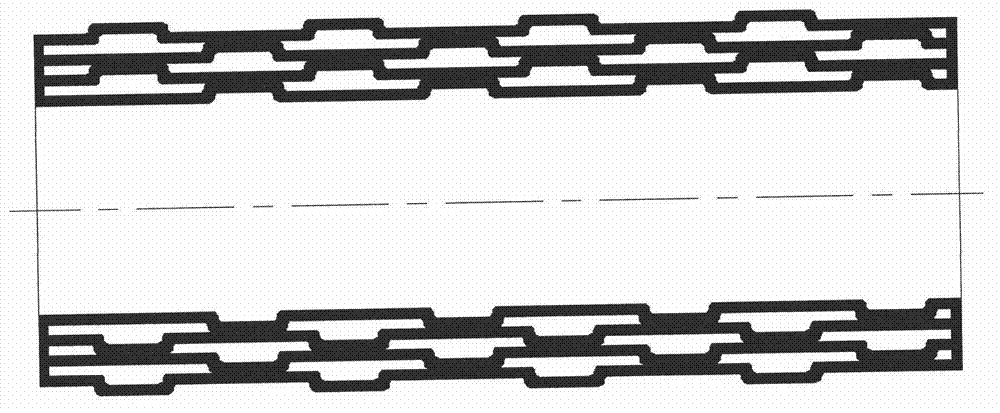

[0027] The heat insulation layer has a cylindrical structure, including a cylinder body and two bucket covers;

[0028] The barrel body is made of multiple layers of stainless steel plates; the barrel cover is made of a single layer of stainless steel plates;

[0029] The two barrel covers are respectively welded to the two ends of the barrel body;

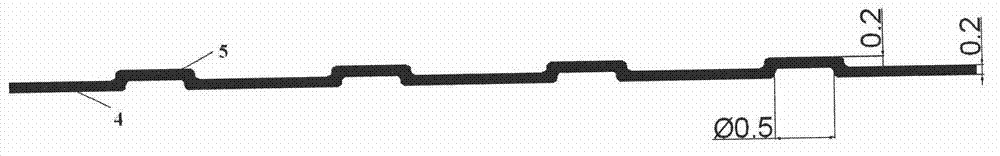

[0030] Each layer of the multi-layer stainless steel plate has a convex structure, and the convex structure is made by using a knurling process; the convex area on each layer of stainless steel plate accounts for 40% of the total area of the stainless steel plate;

[0031] The thickness of each layer of stainless steel plate 4 is 0.2 mm, the diameter of the pro...

Embodiment 2

[0038] The only difference from the embodiment is that a non-metallic heat insulating material 6 is also provided between two adjacent layers of stainless steel plates, such as Figure 4 Shown; the non-metallic insulation material is glass fiber wool, glass fiber shaped blocks or porous silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com