Remote monitoring device of trenchless drilling machine

A remote monitoring, non-excavation technology, applied in the direction of electrical program control, comprehensive factory control, signal transmission system, etc., can solve the problems of reduced life of drilling rigs, prolonging construction time, increasing conflicts between users and manufacturers, etc., to improve service life , Simple structure, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

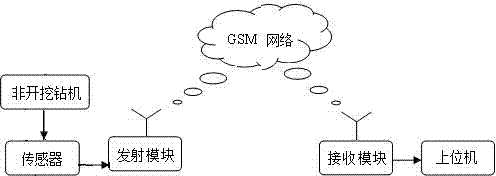

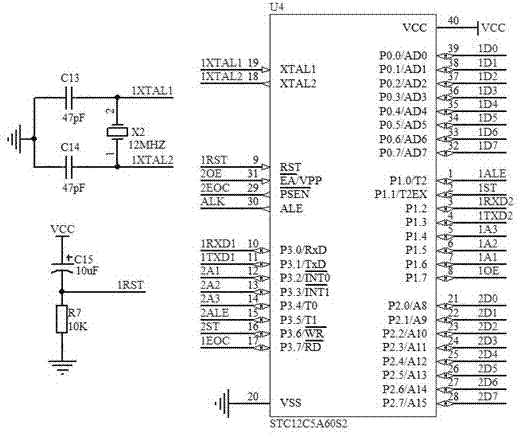

[0043] Embodiment 1: The structure of a remote monitoring device for a non-excavation drilling rig of the present invention is as follows figure 1 As shown, it includes a sensor installed on the non-excavation drilling rig, a transmitting module, a receiving module and a host computer. The sensor is connected to the transmitting module, the transmitting module communicates with the receiving module through the GSM network, and the receiving module is connected to the host computer.

[0044] There are 16 sensors installed on the corresponding positions of the non-excavation drilling rig, such as the pressure sensor and flow sensor installed at the oil outlet of the non-excavation drilling rig hydraulic pump station, and the temperature sensor installed in the oil tank of the non-excavation drilling rig hydraulic pump station , the speed sensor installed at the power head of the non-excavation drilling rig, etc., the sensor is used to collect the working condition parameters and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com