Baking cooling equipment

A kind of cooling equipment and equipment technology, which is applied in lithium battery manufacturing, lithium battery baking and cooling fields, can solve the problems of inability to detect whether the pressure meets the demand, improper heating of the baking oven, uneven heating of the battery, etc., to achieve value maximization, Easy model change and precise operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

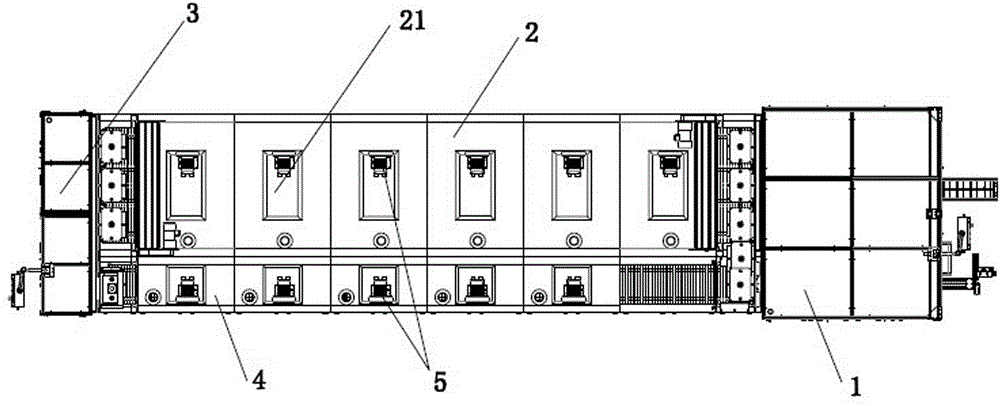

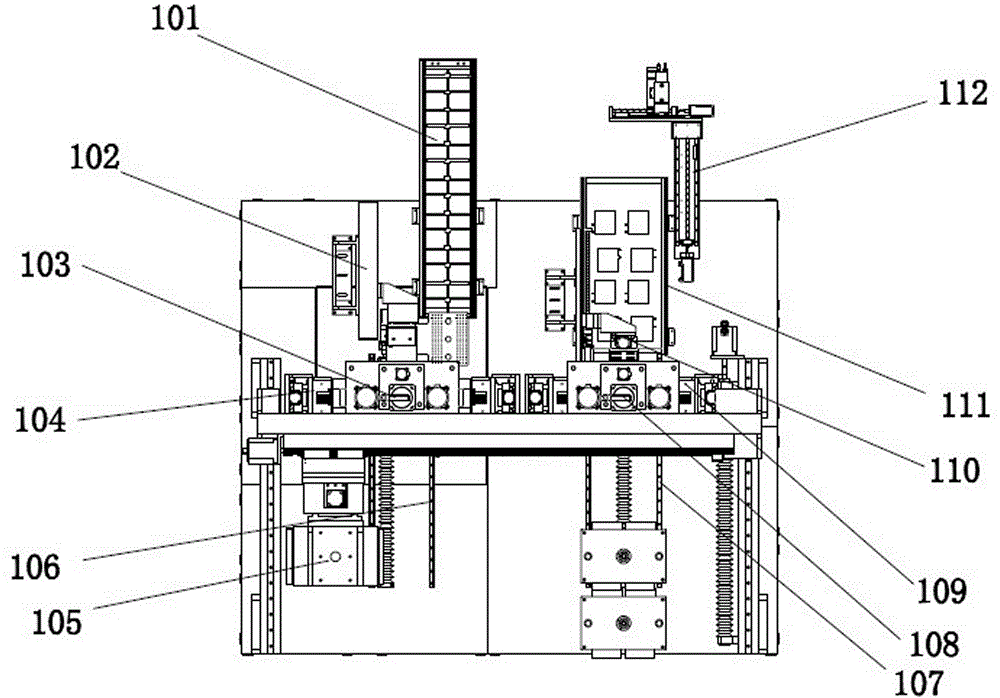

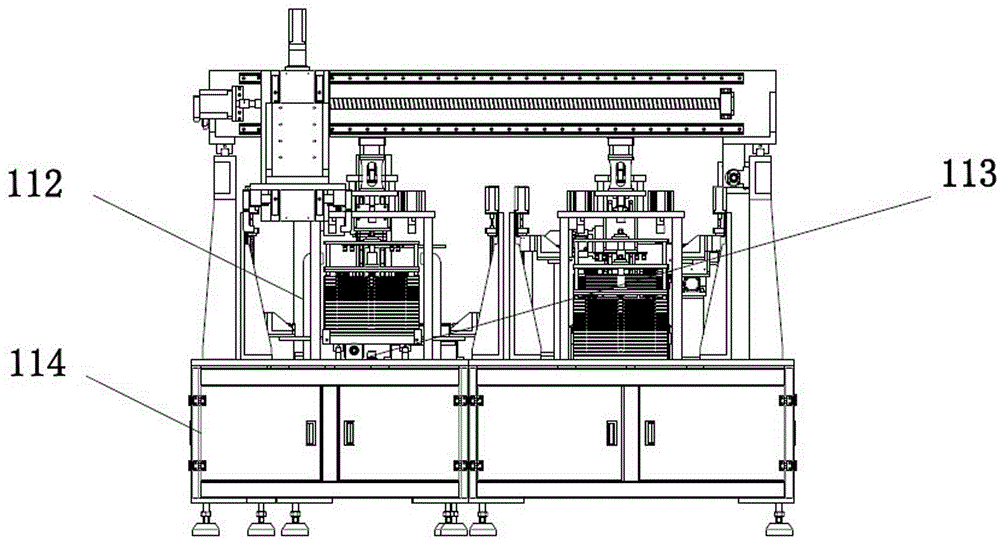

[0022] see Figure 1 to Figure 7 The baking and cooling equipment of the present invention includes a baking area 2, a cooling area 4 juxtaposed with the baking area 2, the conveying starting point of the baking area 2 is provided with an automatic upper and lower clamp device 1, and the conveying end point of the baking area 2 There is a fixture transfer area 3. The automatic upper and lower fixture equipment 1 includes a side-by-side loading mechanism and a blanking mechanism. The loading mechanism is facing the baking area 2. According to the conveying direction of the baking area 2, a feeding pull belt 101, a positioning and locking nut mechanism 103 and Fixture transfer slide table one 106, the upper battery manipulator 102 is arranged on the feeding pull belt 101, a pair of clamp lifting manipulators one 104 is arranged on the lateral direction of the positioning and locking nut mechanism one 103, and the positioning and locking nut mechanism one 103 is provided below T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com