Integrated energy extracting device for power electronic equipment

An energy harvesting device and power electronics technology, applied in the directions of transformer/inductor coil/winding/connection, reactive power compensation, reactive power adjustment/elimination/compensation, etc. Performance requirements, cable threading difficulties and other problems, to achieve the effect of shortening the production cycle, easy implementation, and good heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

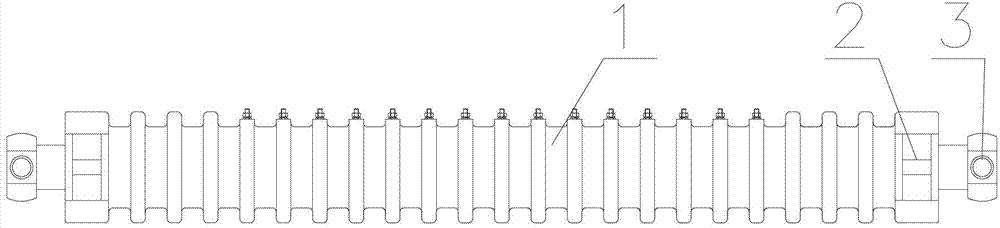

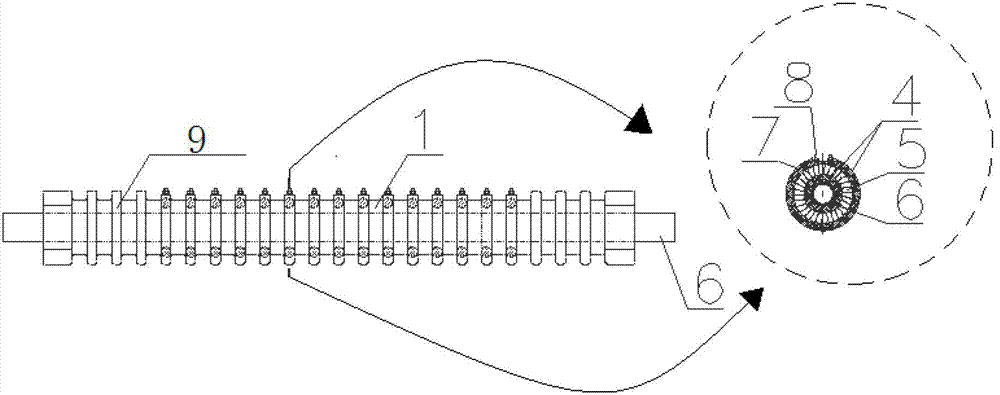

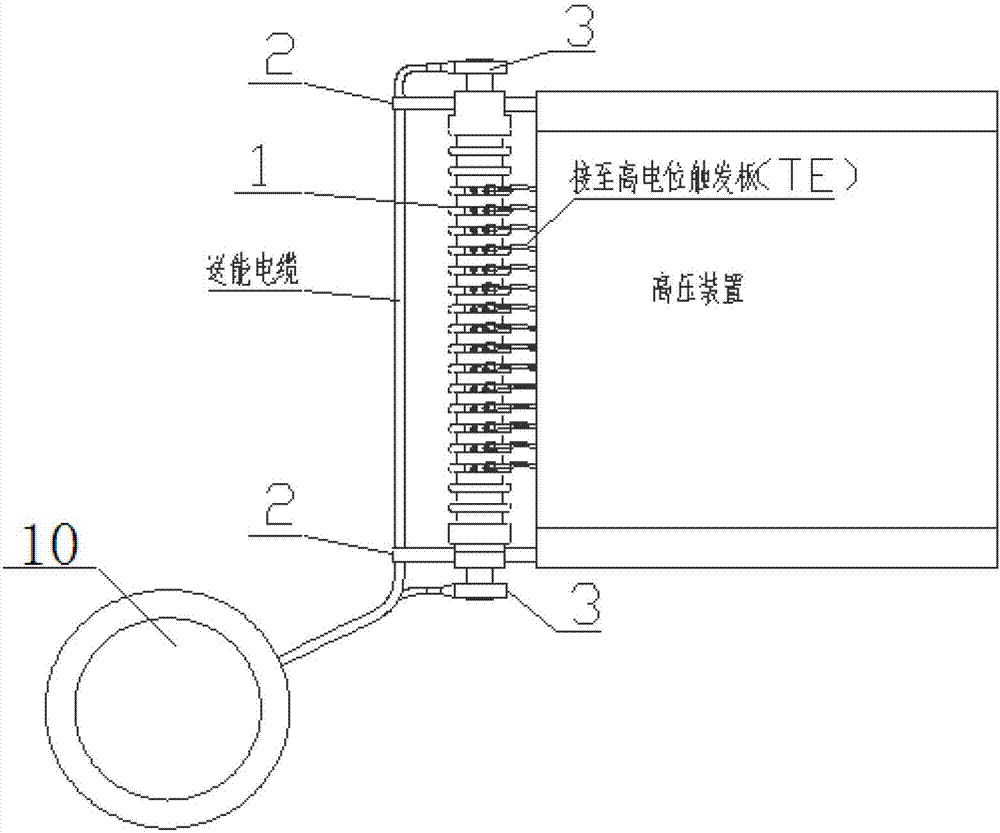

[0028] An integrated energy harvesting device for power electronic equipment provided in this embodiment, its structure diagram is as follows figure 1 As shown, it includes a current converter 1, a cable fixing device 2, a primary side terminal 3 and a transformer 10; this embodiment takes two cable fixing devices as an example for illustration. In the axial direction of the current transformer 1, there are two symmetrical cable fixing devices 2 that pass through the center of the current transformer 1; at the same time, two primary side terminals 3 are respectively arranged at both ends of the current transformer 1, each One end of each primary-side terminal 3 is connected to the lead-out cable of the power transformer, and the other end is connected to the hard conductor 6 of the primary winding of the current transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com