Structures with surface-embedded additives and related manufacturing methods

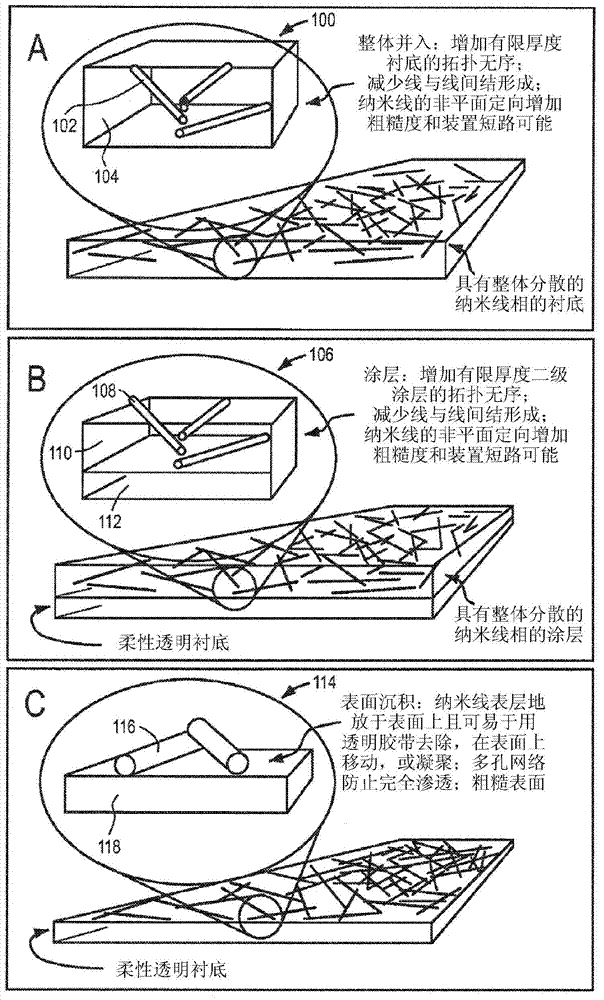

A technology of embedding structure and additives, which is applied to the device of coating liquid on the surface, pretreatment of the surface, transportation and packaging, etc., which can solve the problems of environmental damage, acid and alkali sensitivity, and ITO coating is fragile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

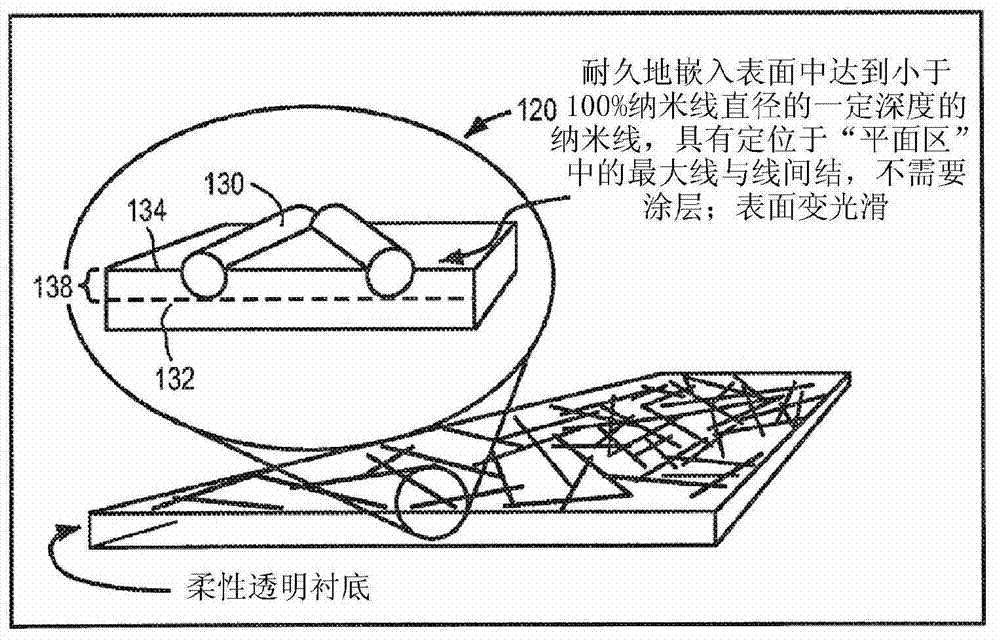

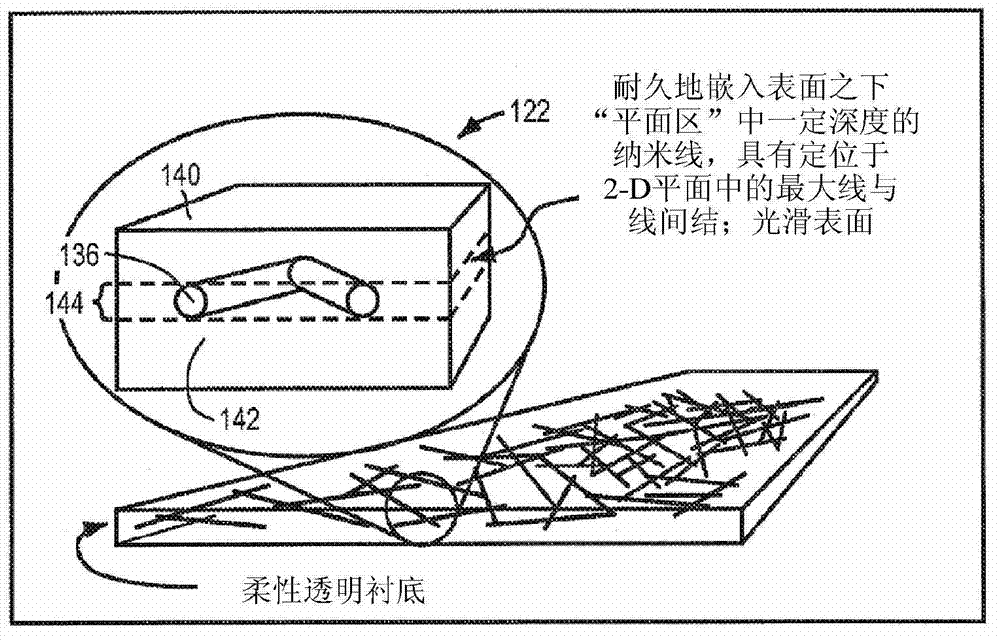

Method used

Image

Examples

example 1

[0178] Formation of transparent conductive electrodes via one-step embedding

[0179]Silver nanowires (diameter = 90 nm and length = 60 μm) were vortexed for 5 s and dispersed in isopropanol (50 vol %) and 2,2,2-trifluoroethanol (50 vol %) at a concentration of 5 mg / ml ( Alfa Aesar (Alfa Aesar, 99%+) solution. Blades spaced 1 mil apart with flat sheets of clear acrylic (polymethyl methacrylate, Sign Mart, Inc.) pulled at 3 in / sec at 20°C and 23% humidity , to cup a solution containing silver nanowires onto an acrylic sheet. 0.5 ml of the nanowire-containing solution adequately covered a half square foot of acrylic sheet. This formulation and procedure yielded efficient solvent-embedded silver nanowires such that the nanowires were partially exposed to the surface of the acrylic sheet, as detected by a Jenway UV-visible spectrophotometer and SP4-Keithley four-point probe The system was measured to exhibit a light transmittance T of 86.6% and a sheet resistance R of 29±6Ω / sq ...

example 2

[0181] Formation of transparent conductive electrodes via two-step embedding

[0182] Silver nanowires (diameter = 90 nm and length = 60 μm) were dispersed in isopropanol at a concentration of 2.5 mg / ml and then pulled with a Mayer wire with a wire separation distance of 20 mils and pulled at a speed of 2.5 in / sec. rod (Gard Co.), to apply it to the surface of clear acrylic (polymethyl methacrylate, Synmate). After coating, the resulting nanowire network was removed by inverting the nanowire network face down onto a circular cross-section container of 100 mm x 20 mm diameter containing 40 ml of tetrahydrofuran (J.T. Baker, 99.5%, stabilized with BHT) at the bottom. The nanowire network and acrylic substrate were exposed to tetrahydrofuran vapor for 40 minutes. This formulation and procedure produced silver nanowires efficiently solvent-embedded into the surface of the acrylic substrate, exhibiting a transmittance T of 74.3% including the acrylic substrate and a sheet resistan...

example 3

[0184] Formation of transparent conductive electrodes via two-step embedding

[0185] Silver nanowires (diameter = 90 nm and length = 60 μm) were dispersed in methanol (Sigma Aldrich, 99%+) at a concentration of 1 mg / ml and then heated at 20°C and 30% humidity It was applied to polycarbonate substrates (Makrolon )superior. The vaporization rate of the methanol, together with the spray gun settings that dispense a very fine atomized cone pattern from the nozzle, produces a substantially vaporized spray before the methanol sprayed from the nozzle reaches 9 inches from the substrate. Methanol was used to effectively suspend the nanowires, and the methanol and atomization air pressure acted as propellants to transport the nanowires to the substrate. However, methanol substantially vaporizes and does not wet the substrate surface, thereby avoiding or reducing uneven wetting of the substrate surface, which can cause migration, agglomeration, coffee ring staining ( coffee-stain r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com