Cathode wire connector for electric dust collector

A connection device, electrostatic precipitator technology, applied in the direction of electrode conveying device, electrostatic separation, etc., can solve the problems of unreliable fastening method, insufficient cathode wire strength, unreliable connection device, etc., to ensure the operating voltage and rapping effect , to ensure the efficiency of operation and dust collection, to ensure long-term reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

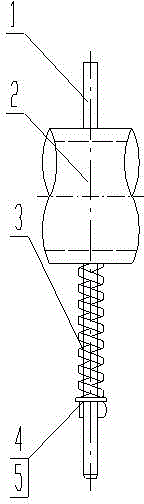

[0012] from figure 1 It can be seen that the present invention includes a cathode wire 1, a cathode frame 2, and a spring connection assembly, the spring connection assembly is composed of a spring 3, a washer 4 and a back-stop pin 5; the upper end of the cathode wire 1 is fixed on the upper frame of the cathode frame 2 by bolts; The lower frame of the cathode frame 2 has a through hole, and the cathode wire 1 passes through the through hole of the cathode frame 2, the center of the spring 3 and the washer 4, and is limited and fixed by the stop pin 5. According to the thickness of the wire diameter of the cathode wire 1, a spring with a tension force of 10-100 N can be selected. During the operation of the electrostatic precipitator, the high-temperature flue gas causes the length of the heated wire body of the cathode wire 1 to expand and contract, and the tension force of the spring 3 of the spring connection component is automatically adjusted to ensure the straightness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com