Steel strip feeding system of continuous casting crystallizer

A continuous casting crystallizer and crystallizer technology, applied in the field of metallurgy, can solve problems such as loose defects in the core of the slab, unsuitable feeding amount of the steel strip, and unsteady operation of consumable cold materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

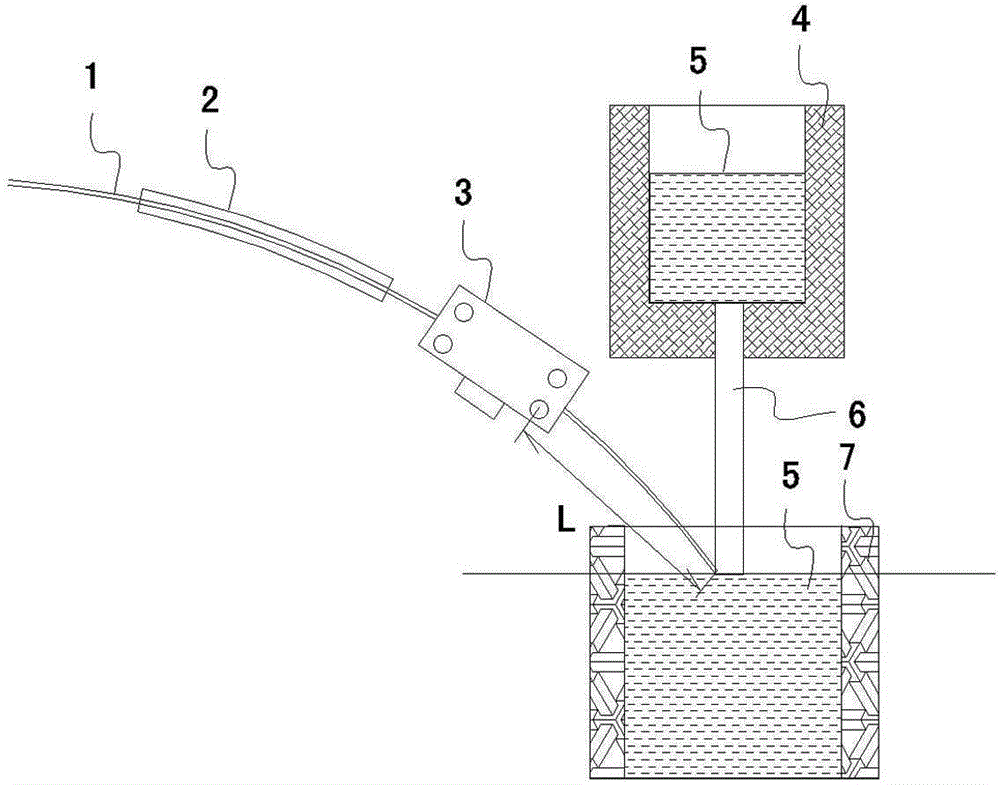

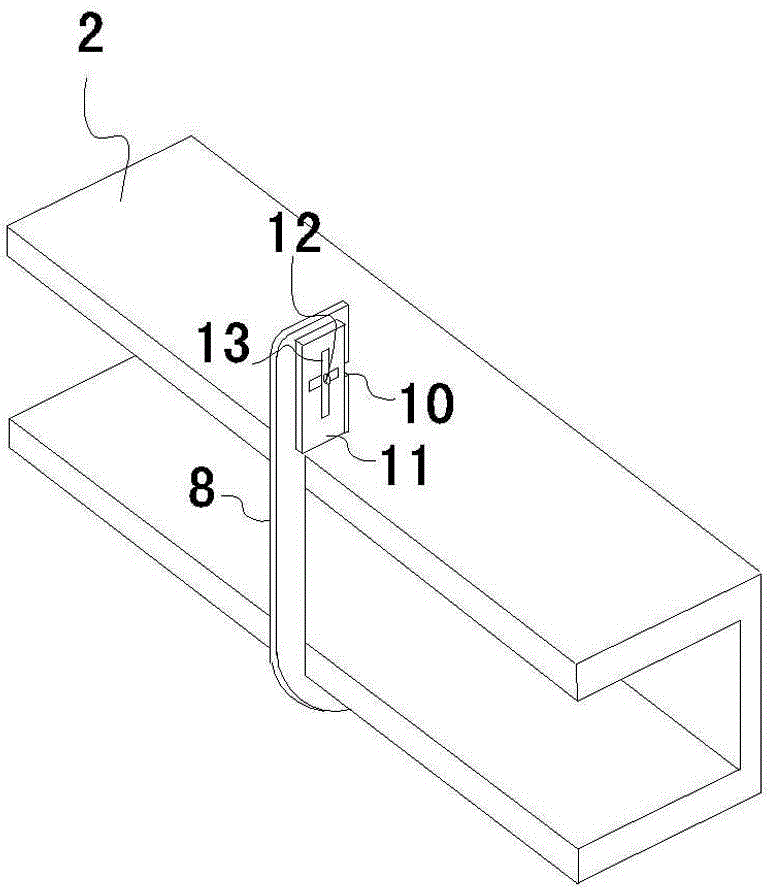

[0014] As shown in the figure, the belt feeding system of the continuous casting crystallizer includes guide pipe 2, electromagnetic vibrator 3, tundish 4 and crystallizer 7; steel belt 1 enters electromagnetic vibrator 3 from guide pipe 2 and then enters mold 7 , to the crystallizer 7 into the steel strip 1; the molten metal 5 is continuously fed into the crystallizer 7 from the tundish 4 through the submerged nozzle 6 fixedly connected with the bottom of the tundish 4, and the billet for the next step is continuously Pulled out from the crystallizer 7; when the steel strip 1 is sent into the crystallizer 7, the electromagnetic vibrator 3 of the electromagnet gives the steel strip 1 a forced resonance; it is characterized in that the guide tube 2 adopts ì-shaped; a sealing jig 8 is fixed at the longitudinal opening of the guide tube 2; one end of the jig 8 can rotate around the rotating shaft, and the other end of the jig 8 is connected to the locking member 11 through the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com