Lock blank combined automatic cutting machine

A combined, cutting machine technology, applied in shearing devices, metal processing machinery parts, devices for shearing and forming blanks, etc., can solve the problems of inability to meet mass production, low productivity, etc., achieve a clean and environmentally friendly working environment, and increase production capacity , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

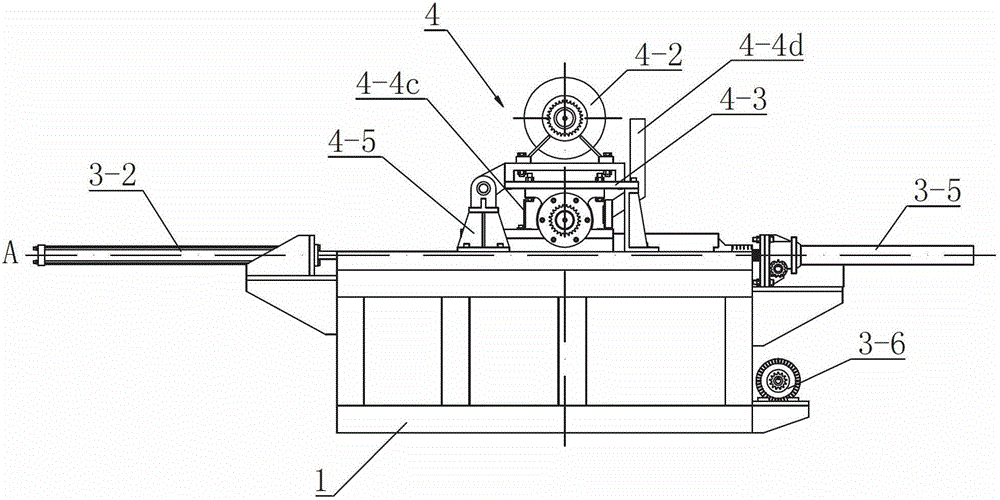

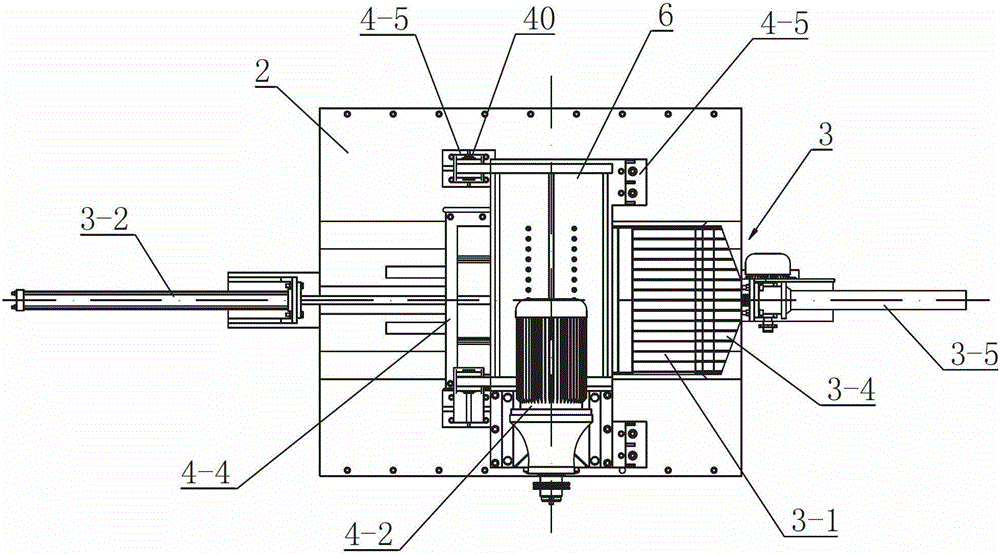

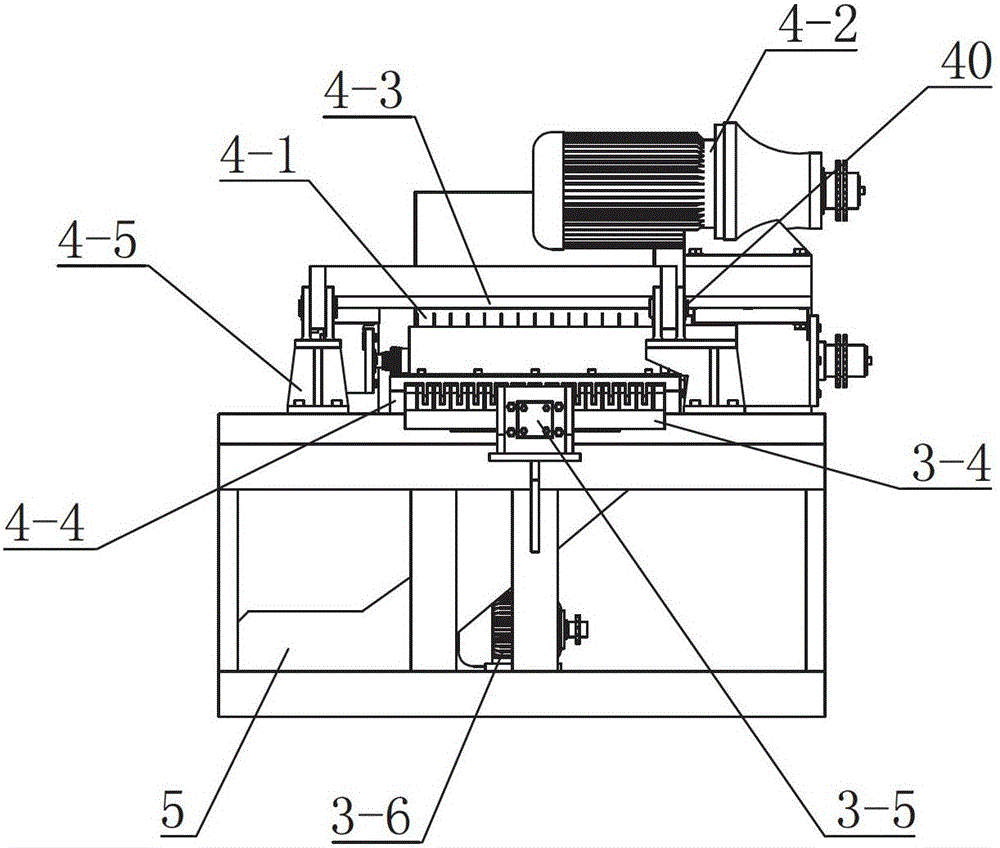

[0027] Such as figure 1 , figure 2 and image 3 As shown, the lock blank combined automatic cutting machine of this embodiment includes a body support 1 , a processing table 2 , a feeding mechanism 3 , a processing mechanism 4 and a discharge chute 5 . Among them, the feeding mechanism 3 includes a material tray 3-1 and a material tray pushing oil cylinder 3-2; the processing mechanism 4 includes a combined cutter head 4-1, a cutting drive motor 4-2, a tool mounting frame 4-3 and a cutting table 4-4 . A blanking opening a is processed on the surface of the processing table 2, and the discharge trough 5 is arranged on the body support 1, and its inlet end is located below the blanking opening a. For ease of description, the figure 1 The direction of the axis A in defines left and right.

[0028] Also refer to Figure 4 and Figure 5 , the processing table 2 is installed on the body support 1, and some bolt holes are processed on the processing table 2 table for installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com