Production method of garnet microwave ferrite with narrow line width and high dielectric constant

A technology with high dielectric constant and manufacturing method, which is applied in the field of microwave technology and magnetic materials, can solve the problems of low dielectric constant and low Curie temperature, etc., and achieve the effect of facilitating debugging and improving debugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

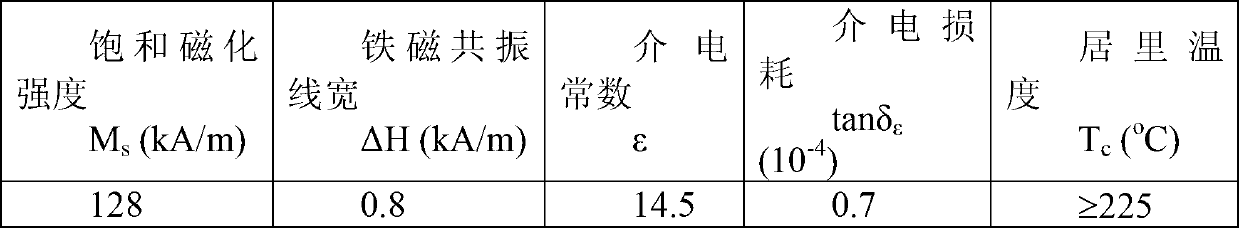

example 1

[0030] The manufacturing process is: 1) Raw material processing → 2) Calculation and weighing according to the formula → 3) Primary ball milling (raw material mixing) → 4) Pre-calcination → 5) Secondary ball milling → 6) Drying and granulation → 7) Compression molding → 8) Sintering.

[0031] ①According to the chemical formula

[0032] Y 3-x′-2x-z-p-q Bi x′ Ca 2x+z+p+q V x Gez In y sn p Ti q mn w Al w′ Fe 5-x-y-z-p-q-w-w′-δ o 12

[0033] Take: x=0.15;y=0;z=0.07;x'=0;p=0.20;q=0.05;w=0;w'=0, calculate the required raw materials. Use Y with a purity of ≥99.9% and burnt treatment 2 o 3 , and analytically pure Fe 2 o 3 ,CaCO 3 ,V 2 o 5 ,GeO 2 ,SnO 2 , TiO 2 As the raw material, weigh out the corresponding weight of the raw material. ② Put the weighed raw materials into the ball mill jar, and add stainless steel balls and alcohol according to the ratio of material: ball: alcohol = 1: 3: 1, and discharge the material after 12 hours of ball milling. The ball mi...

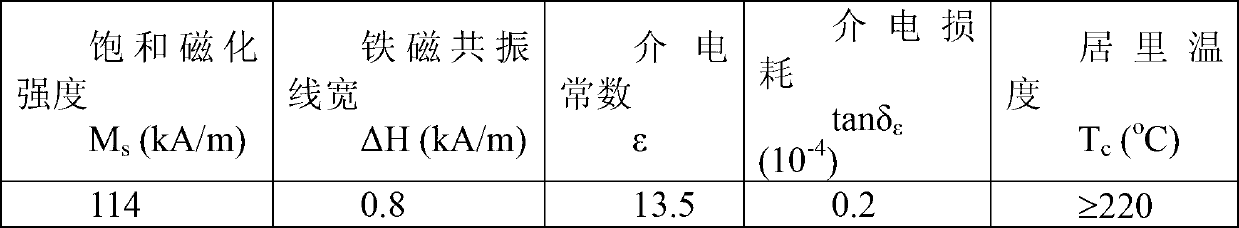

example 2

[0038] ①According to the chemical formula

[0039] Y 3-x′-2x-z-p-q Bi x′ Ca 2x+z+p+q V x Ge z In y sn p Ti q mn w Al w′ Fe 5-x-y-z-p-q-w-w′-δ o 12

[0040] Take: x=0.23;y=0.10;z=0.10;p=0.12;q=0.05;x′=0;w=0;w′=0, and calculate the required raw materials. Use Y with purity ≥ 99.9% and burnt treatment 2 o 3 and analytically pure Fe 2 o 3 ,CaCO 3 ,V 2 o 5 ;In 2 o 3 ,SnO 2 , TiO 2 ,GeO 2 As the raw material, weigh out the corresponding weight of the raw material. ② Put the weighed raw materials into a ball mill jar, and add steel balls and alcohol according to the ratio of material: balls: alcohol = 1: 3: 1.0, and discharge after 12 hours of ball milling. The ball milling tank is made of stainless steel to reduce the abrasive Fe entering the material during the ball milling process. After the slurry is dried, pass through a 30-mesh sieve and put it into a special sagger. ③Put the sagger containing the powder into a furnace with an oxidizing atmosphere for...

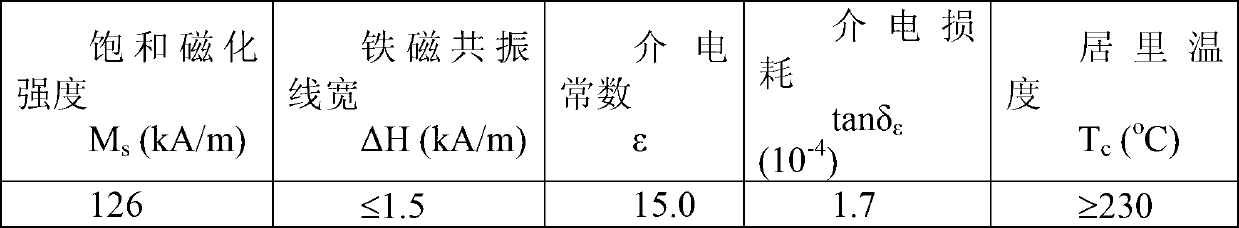

example 3

[0045] ①According to the chemical formula

[0046] Y 3-x′-2x-z-p-q Bi x′ Ca 2x+z+p+q V x Ge z In y sn p Ti q mn w Al w′ Fe 5-x-y-z-p-q-w-w′-δ o 12

[0047] Take: x=0.20; x′=0.45; y=0; z=0.05; p=0.20; q=0.05; w=0; w′=0, and calculate the required raw materials. Use Y with a purity of ≥99.9% and burnt treatment 2 o 3 and analytically pure Bi 2 o 3 , Fe 2 o 3 ,CaCO 3 ,V 2 o 5 ,SnO 2 ; TiO 2 ; GeO 2 As the raw material, weigh out the corresponding weight of the raw material. ② Put the weighed raw materials into the ball mill jar, and add stainless steel balls and alcohol according to the ratio of material: ball: alcohol = 1: 3: 1, and discharge the material after 12 hours of ball milling. The ball milling tank is made of stainless steel to reduce Fe worn during ball milling into the material. The slurry is dried and passed through a 30-mesh sieve, and put into a special corundum crucible. ③Put the corundum crucible with the powder into a furnace with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ferromagnetic resonance linewidth | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap