Method for fabricating side rough surfaces of prefabricated part

A production method and technology for prefabricated components, which are applied in the field of building construction, can solve the problem of inability to make rough surfaces by washing, and achieve the effects of prolonging the hardening time and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to facilitate a further understanding of the structure of the present invention, the present invention will be further described below in conjunction with specific examples.

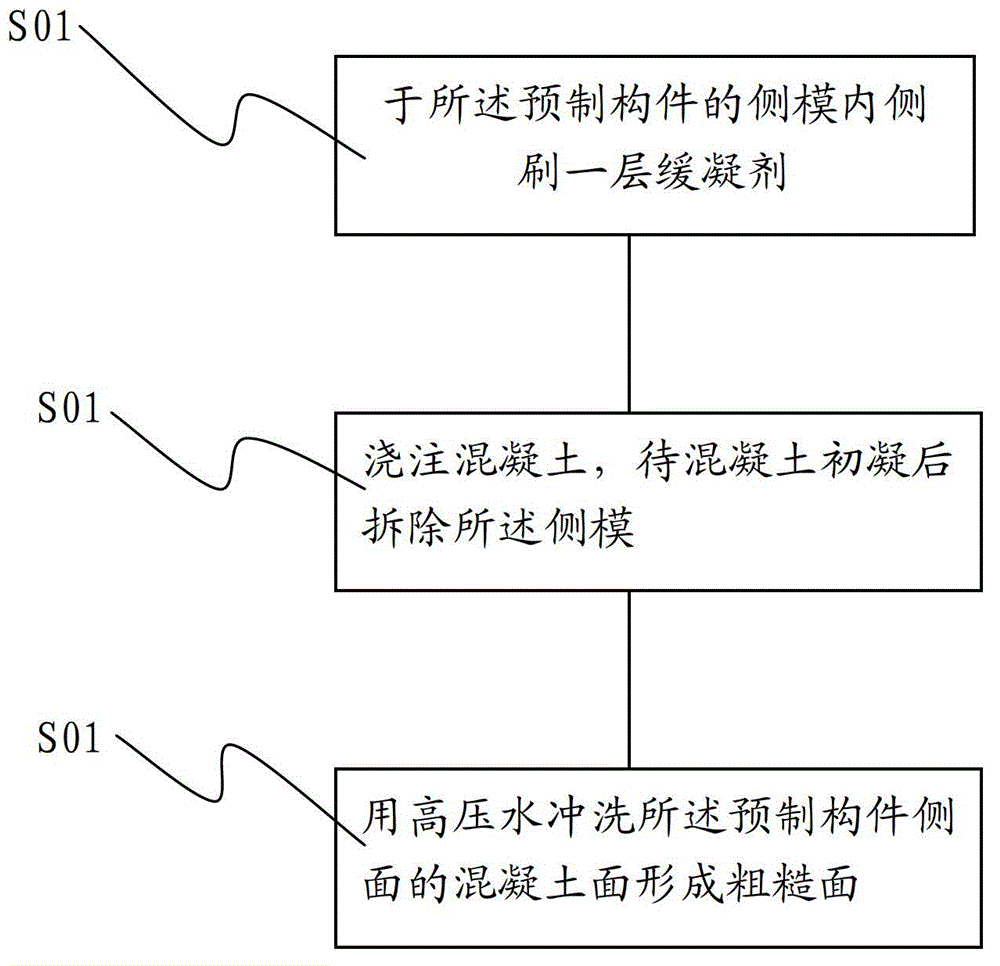

[0012] The preparation method 1 of the rough side surface of the prefabricated component of the present invention uses a layer of retarder on the inside of the side form of the prefabricated component. The retarder is an admixture that delays the setting time of concrete and has no obvious influence on the strength of the later stage. The main component is Polyhydroxyl compounds, hydroxycarboxylates and their derivatives, high-sugar lignosulfonate, also known as retarded water-reducers because of their water-reducing effect, in addition, some inorganic salts such as zinc chloride, borate , Various phosphates also have retarding effect, the dosage is 0.1-0.6% of the cement dosage, the retarder is suitable for continuous pouring concrete, mass concrete, ready-mixed concrete and pumped concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com