Polypropylene toughening modifying agent and polypropylene modified product thereof

A toughening modifier, polypropylene technology, applied in the field of polypropylene toughening modifier and its polypropylene modified products, can solve the problem of affecting the safety of PPR pipeline transportation water system, affecting the construction and installation of PPR pipeline, PPR pipe material brittleness and other problems, to achieve good economic and social benefits, improved impact strength, and good toughening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

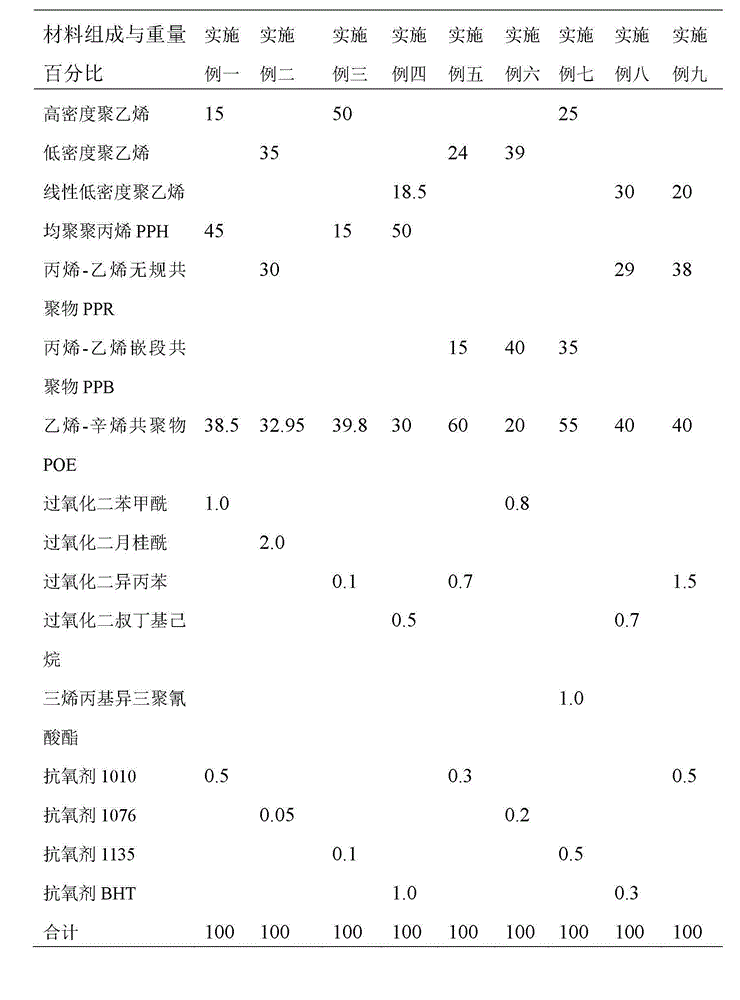

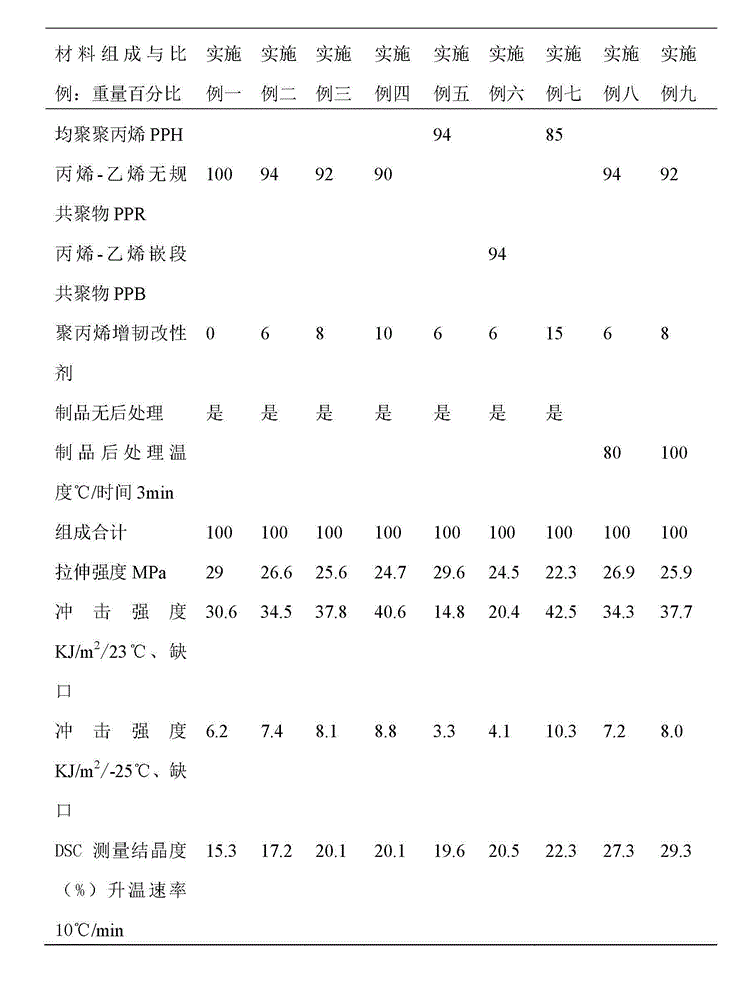

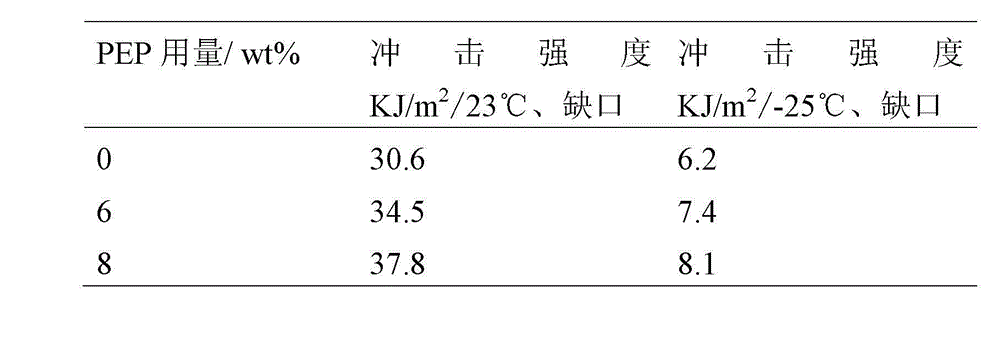

[0023] A kind of polypropylene toughening modifier of the present invention, composition and ratio:

[0024] Polyethylene 15-50wt.%, polypropylene 15-50wt.%, ethylene and octene copolymer POE 20-55 wt.%, initiator 0.1-2.0 wt.%, antioxidant 0.05-1.0 wt.%.

[0025] Polyethylene includes high-density polyethylene, low-density polyethylene, and linear low-density polyethylene; polypropylene includes homopolypropylene PPH, propylene and ethylene random copolymer PPR, propylene and ethylene block copolymer PPB; ethylene and octene Copolymer POE; initiators include dibenzoyl peroxide, dilauroyl peroxide, dicumyl peroxide, di-tert-butyl hexane [2,5-dimethyl-2,5 bis(tert Butylperoxy)hexane], triallyl isocyanurate, antioxidants include 1010, 1076, 1135, BHT.

[0026] Preferably, polyethylene 18-40wt.%, polypropylene 20-45wt.%, ethylene-octene copolymer POE 25-50 wt.%, initiator 0.3-1.5 wt.%, antioxidant 0.1-0.8 wt. %.

[0027] Preferably, the initiator is dicumyl peroxide or di-tert-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com