Low-emission and low-pollution EPDM (Ethylene-Propylene-Diene Monomer) rubber and preparation method thereof

A low-pollution, low-emission technology, applied in the field of EPDM rubber and its preparation, can solve the problem of odor emission, there is no good way to solve and improve, rubber smell, discomfort, etc., to improve the air quality in the car, low emission , to meet the effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

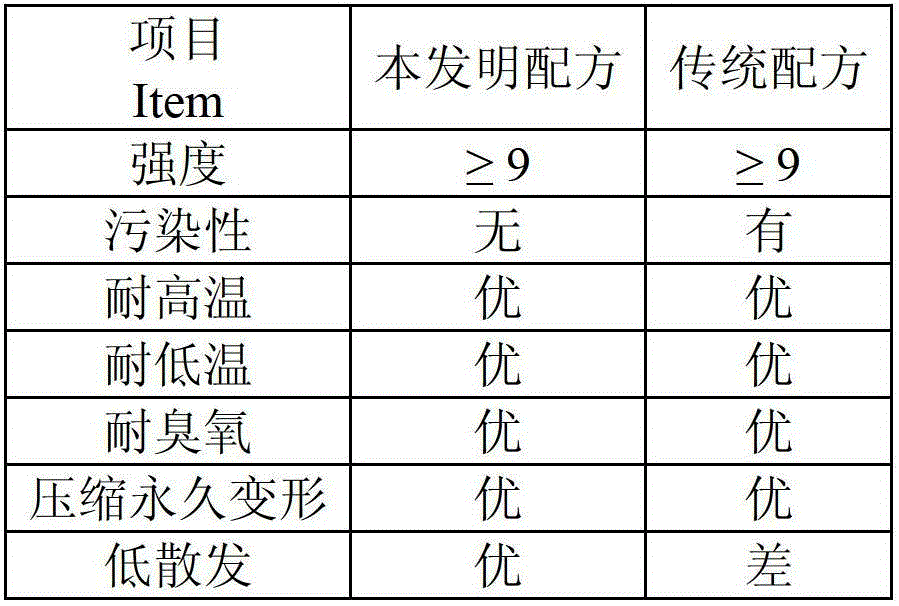

Image

Examples

Embodiment 1

[0013] The formula ratio is as follows in parts by weight: 90 parts of EPDM rubber, 3.5 parts of zinc oxide, 0.8 parts of stearic acid, 40 parts of carbon black N55040 parts, 228025 parts of paraffin oil, 3.5 parts of peroxide vulcanizing agent DCP, and 0.3 parts of sulfur 1.5 parts of anti-aging agent RD, 0.3 parts of accelerator DTDM;

[0014] The preparation method of the EPDM rubber of described low emission and low pollution, the steps are as follows:

[0015] (1) Mixing: Put EPDM rubber into the open mill, adjust the roller distance to 5mm, and masticate at 35°C for 8 minutes; after the mastication is completed, put in zinc oxide, stearic acid, and anti-aging agent RD, and mix well , continue to put in carbon black N550 and paraffin oil 2280, mix evenly, continue to put in accelerator DTDM, sulfur, and peroxide vulcanizing agent DCP, after 4 minutes of feeding, adjust the roller distance to 1mm, make four triangle bags, and finally put the roller Adjust the distance to ...

Embodiment 2

[0019] The formula ratio is as follows in parts by weight: 110 parts of EPDM rubber, 6.5 parts of zinc oxide, 1.2 parts of stearic acid, 60 parts of carbon black N55060 parts, 228035 parts of paraffin oil, 6.5 parts of peroxide vulcanizing agent DCP, and 0.7 parts of sulfur , 2.5 parts of anti-aging agent RD, 0.7 parts of accelerator DTDM;

[0020] The preparation method of the EPDM rubber of described low emission and low pollution, the steps are as follows:

[0021] (1) Mixing: Put EPDM rubber into the open mill, adjust the roller distance to 6mm, and masticate at 45°C for 12 minutes; after the mastication is completed, put in zinc oxide, stearic acid, and anti-aging agent RD, and mix evenly , continue to put in carbon black N550 and paraffin oil 2280, mix evenly, continue to put in accelerator DTDM, sulfur, and peroxide vulcanizing agent DCP, after 6 minutes of feeding, adjust the roller distance to 1mm, make four triangle bags, and finally put the roller Adjust the distan...

Embodiment 3

[0025] The formula ratio is as follows in parts by weight: 100 parts of EPDM rubber, 5 parts of zinc oxide, 1 part of stearic acid, 50 parts of carbon black N55050, 228030 parts of paraffin oil, 5 parts of peroxide vulcanizing agent DCP, 0.5 parts of sulfur, anti-aging 2 parts of agent RD, 0.4 parts of accelerator DTDM;

[0026] The preparation method of the EPDM rubber of described low emission and low pollution, the steps are as follows:

[0027] (1) Mixing: Put EPDM rubber into the open mill, adjust the roller distance to 6mm, and masticate at 40°C for 10 minutes; after the mastication is completed, put in zinc oxide, stearic acid, and anti-aging agent RD, and mix evenly , continue to put in carbon black N550 and paraffin oil 2280, mix evenly, continue to put in accelerator DTDM, sulfur, and peroxide vulcanizing agent DCP, after 4 minutes of feeding, adjust the roller distance to 2mm, make four triangle bags, and finally put the roller Adjust the distance to 7mm for the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com